darrencambs

Member

- Messages

- 6

Hi all,

I've been registered on this forum for a while now, but have been lurking quietly in the background most of the time! Great site by the way - amazing how much I've managed to learn from here.

Unfortunately, I discovered this forum after I'd purchased a Cosmo welder - probably would have gone for a different machine if I'd have known about the bad reputation SIP / Cosmo have

Anyway, I have run about half a dozen small reels through it over the last few months without any problems. Then within a couple of days of putting in a large reel, I started to experience problems with the wire feed.

The motor was turning, but the rollers were slipping and not feeding the wire through.

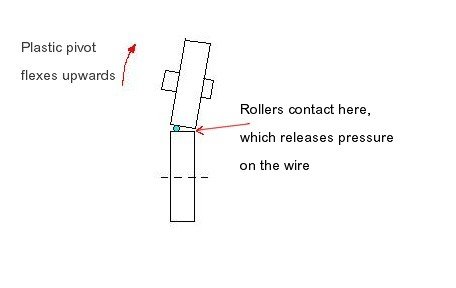

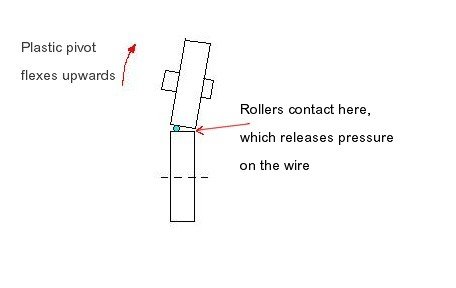

On closer inspection, I could see that the plastic pivot that carriers the idler roller was flexing. This resulted in the rollers being out of true, and losing the grip on the wire.

I came up with a simple solution that stops this from happening. So far, I've run another large reel through without any problems at all - wire feed is much more stable and no signs of slipping.

A couple of photos below to show the simple solution. Hopefully this will be of use to anyone who's suffering these sort of problems with their SIP / Cosmo machine. Probably worth trying before changing to a steel liner?

I've been registered on this forum for a while now, but have been lurking quietly in the background most of the time! Great site by the way - amazing how much I've managed to learn from here.

Unfortunately, I discovered this forum after I'd purchased a Cosmo welder - probably would have gone for a different machine if I'd have known about the bad reputation SIP / Cosmo have

Anyway, I have run about half a dozen small reels through it over the last few months without any problems. Then within a couple of days of putting in a large reel, I started to experience problems with the wire feed.

The motor was turning, but the rollers were slipping and not feeding the wire through.

On closer inspection, I could see that the plastic pivot that carriers the idler roller was flexing. This resulted in the rollers being out of true, and losing the grip on the wire.

I came up with a simple solution that stops this from happening. So far, I've run another large reel through without any problems at all - wire feed is much more stable and no signs of slipping.

A couple of photos below to show the simple solution. Hopefully this will be of use to anyone who's suffering these sort of problems with their SIP / Cosmo machine. Probably worth trying before changing to a steel liner?

, with SIP owners all having meetings over the country showing off the modifications they have made, could be the new fashion for the would be boy racer, custom modified SIP welders

, with SIP owners all having meetings over the country showing off the modifications they have made, could be the new fashion for the would be boy racer, custom modified SIP welders