This came up in another thread, but I reckoned it might be of interest as quite a few folks on here seem to be interested in MIG welding for car restoration.

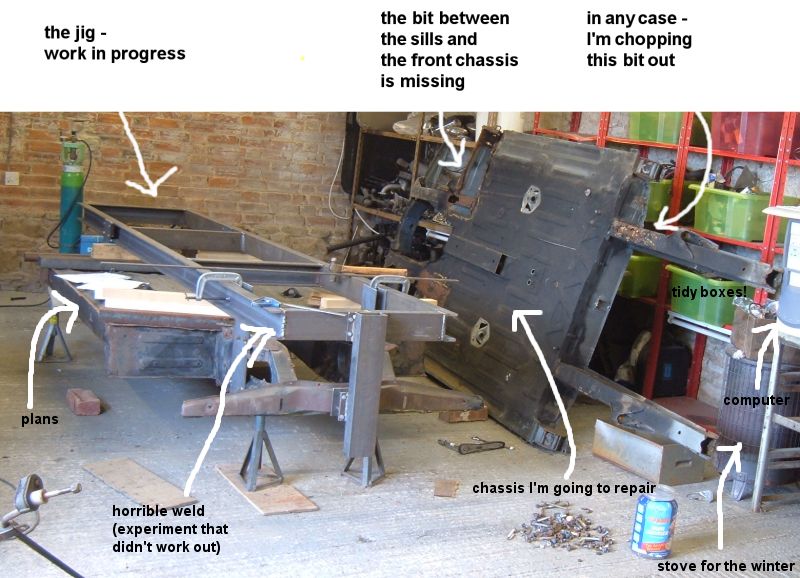

What I was thinking of fabbing as my first project is a "spit" device, possibly with a supporting frame or jig, (malcolms idea!), that would allow you to mount a stripped out bodyshell to it and then rotate the bodyshell through 360 on its long axis.

There are commercial products out there already like the CJAutos Chassis tilter, but at that kind of money it HAS to be cheaper to build something yourself from scratch. It doesn't need to have all the bells and whistles, but the basic spit idea would be perfect for working on the underside of the car. Being able to weld standing up or looking down on the work should improve the quality of the welds too as you will be far more comfortable.

So has anyone fabbed anything like this before? Got any pictures / tips / tricks you would care to share?

I can just see something like this being time well spent at the start of a resto, and hopefully if built with some adjustability in the design could be re-used for subsequent resto / bodywork.

So who is going to get the ball rolling then?

Cheers,

Chris

What I was thinking of fabbing as my first project is a "spit" device, possibly with a supporting frame or jig, (malcolms idea!), that would allow you to mount a stripped out bodyshell to it and then rotate the bodyshell through 360 on its long axis.

There are commercial products out there already like the CJAutos Chassis tilter, but at that kind of money it HAS to be cheaper to build something yourself from scratch. It doesn't need to have all the bells and whistles, but the basic spit idea would be perfect for working on the underside of the car. Being able to weld standing up or looking down on the work should improve the quality of the welds too as you will be far more comfortable.

So has anyone fabbed anything like this before? Got any pictures / tips / tricks you would care to share?

I can just see something like this being time well spent at the start of a resto, and hopefully if built with some adjustability in the design could be re-used for subsequent resto / bodywork.

So who is going to get the ball rolling then?

Cheers,

Chris

.

.

quite rare car' only hundred or so built a nice car in it's day, I built a chassis tilter for the project that I got from street machine magazine I still have the plans for it some where, so simple ,main components are full size Builders trestle, bit of chopping and welding that's it, they worked a treat, they were quite posh back then, most people were still rolling cars on old mattresses, I will dig them out and post them up on here, might be handy/useful on the forum.

quite rare car' only hundred or so built a nice car in it's day, I built a chassis tilter for the project that I got from street machine magazine I still have the plans for it some where, so simple ,main components are full size Builders trestle, bit of chopping and welding that's it, they worked a treat, they were quite posh back then, most people were still rolling cars on old mattresses, I will dig them out and post them up on here, might be handy/useful on the forum.