Having bought a nearly new 160T with the torch absent and Clarke (and their agent) not wanting to talk to me, I got on with converting it to a Euro style torch and decided to take pics so that those of you who'd want to do the same could maybe benefit from my efforts.

The 160T has a sloping front which complicated things a bit. I fashioned a bracket that squared things up and allowed me to position the socket in relation to the drive unit. A far easier solution would be to turn a nylon spacer with a slope but I decided to use the basic tools at hand at the time.

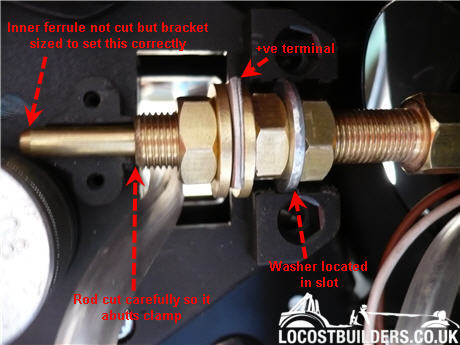

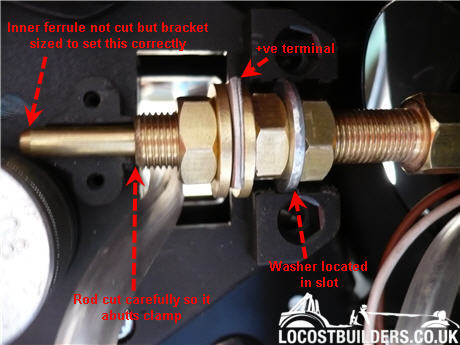

Note that the wire enters the back of the socket offcentre so had to allow for this during the positioning. I fitted the torch lead to the socket as this influences the position of the socket in its housing and acts as a stop for the brass inner ferrule-sleeve.

Drill the clamp to a bit smaller than the new wire ferrule (or leave the clamp screws a teeny bit slack (I think i used a 4.8mm drill for this but check yours first)

Needed a gas solenoid so bought a 240V one and connected it across J1-J3 as per fitting instructions. Had some sound advice from some of the chaps on this forum regarding this and may modify for gas purging later..

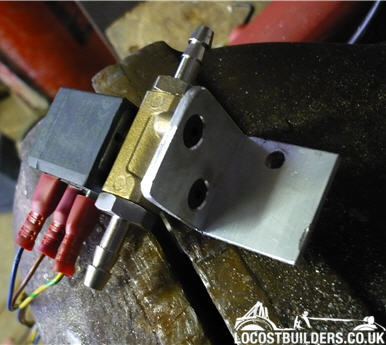

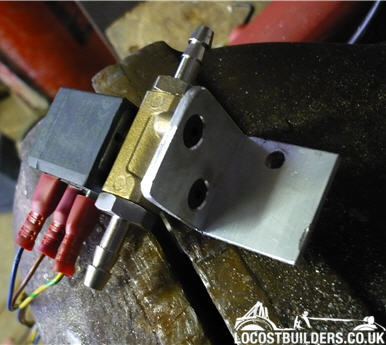

I made a little angle bracket to hold the solenoid valve

I soldered them and used some heat shrink sleeving (as it's 240V !!) The earth was connected too of course !!

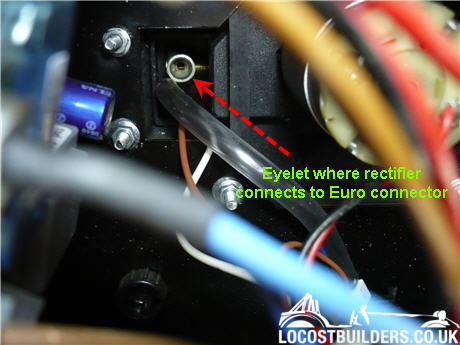

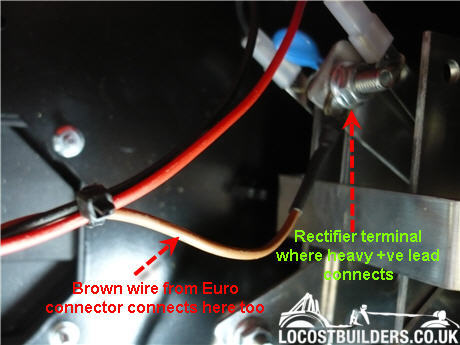

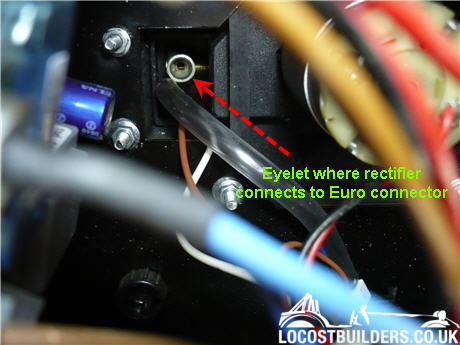

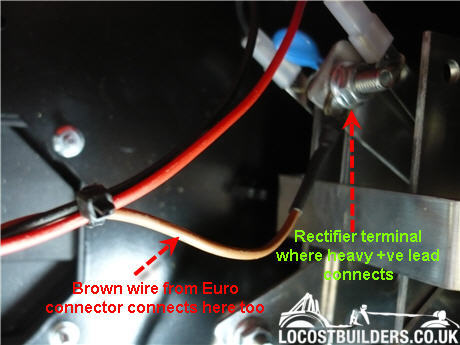

The existing (Clarke) small gauge brown lead I connected to the White torch lead of the Euro socket and the Brown lead i connected to the Torch +VE (the heavy gauge wire that links the rectifier to the Euro connector. I have yet to make a heavy fly lead for this .....

ta da!!

The 160T has a sloping front which complicated things a bit. I fashioned a bracket that squared things up and allowed me to position the socket in relation to the drive unit. A far easier solution would be to turn a nylon spacer with a slope but I decided to use the basic tools at hand at the time.

Note that the wire enters the back of the socket offcentre so had to allow for this during the positioning. I fitted the torch lead to the socket as this influences the position of the socket in its housing and acts as a stop for the brass inner ferrule-sleeve.

Drill the clamp to a bit smaller than the new wire ferrule (or leave the clamp screws a teeny bit slack (I think i used a 4.8mm drill for this but check yours first)

Needed a gas solenoid so bought a 240V one and connected it across J1-J3 as per fitting instructions. Had some sound advice from some of the chaps on this forum regarding this and may modify for gas purging later..

I made a little angle bracket to hold the solenoid valve

I soldered them and used some heat shrink sleeving (as it's 240V !!) The earth was connected too of course !!

The existing (Clarke) small gauge brown lead I connected to the White torch lead of the Euro socket and the Brown lead i connected to the Torch +VE (the heavy gauge wire that links the rectifier to the Euro connector. I have yet to make a heavy fly lead for this .....

ta da!!