- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Home Made Tools and Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swager

- Thread starter Mad Mick

- Start date

Mad Mick

Member

- Messages

- 186

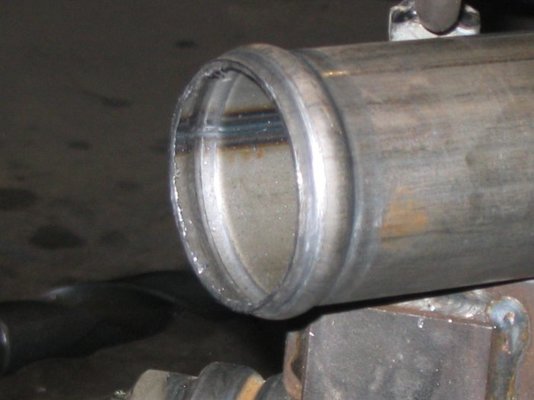

Hi Mr Fluffy,thats what it's mostly for,approx 50mm x 16g and upwards for rad pipes and intercooler pipes etc. It is fairly easy to work,just keep the tube hard up against the stops and keep turning.The business end is just a decent sized bearing with the outer race ground to suit pressed against a heavy boss with matching recess,plus some 40 box,20mm bolts and a self aligning bearing etc.Have you seen what these things normally cost to buy?Will post some pics hopefully ,regards,Mick

Thats exactly what I was thinking of making after having seen the prices. I have had need on a few occasions in the past when I needed to bead ic pipes etc, but I always seemed to get stuck on finding little gears to gear the handle ratio down as pretty much every one I've seen has been geared I thought it HAD to be that way, so it kept getting put on back burner and Id just run a bead of weld on etc. But, if it works direct 1:1 thats perfect for me, Im built like shrek anyway. I can knock up the formers on the lathe to do different profiles and make it into a mini swager or something too.

Nice job, look forward to the other pics.

Nice job, look forward to the other pics.

graffian

Seer unto the end of his beard

- Messages

- 3,812

- Location

- gatwick

I don't have a picture of the business end of my little bead roller. I tried no gears and didn't get on with it. The large roller is over 2" and the small one is cut into the 1" bar the bottom axle is made of.

The gears are from a starter motor, bottom axle runs in old 25mm wheel bearings, the top runs in the remains of my old lathes crossslide nut[chucnk of phoshor bronze] and a bit of tube at the back; the axles are 1" but there is slightly more overhang than I intended though it will bead 12swg tube just as easy as 16swg. The big gear has a clutch in it, didn't really think about it until I chucked the lathe and forgot to save the handle, I now it bolted to the table of my mill and work it with a mole wrench, just goes back and fore as it's got the one way clutch.

The gears are from a starter motor, bottom axle runs in old 25mm wheel bearings, the top runs in the remains of my old lathes crossslide nut[chucnk of phoshor bronze] and a bit of tube at the back; the axles are 1" but there is slightly more overhang than I intended though it will bead 12swg tube just as easy as 16swg. The big gear has a clutch in it, didn't really think about it until I chucked the lathe and forgot to save the handle, I now it bolted to the table of my mill and work it with a mole wrench, just goes back and fore as it's got the one way clutch.