peterd51

happy to be here!

- Messages

- 1,593

Hi Guys!

for years I've had a couple of pieces of angle welded at approx 90 degrees, the angle drifted out as the weld cooled, and I've been thinking of repacing that as it was tricky to use. I was looking at a set of these 90 degree clamps a week or two back but decided they looked a bit too flimsy for me (they were cheap), so I thought I'd have a go at making some.

Here's the basic materials for two clamps...

In the photo, the vertical angle will be welded to the flat plates, one with a hole to have a nut welded over it to take the long thread and the other plate is the tail-stop.

Photo 2 shows the slider parts. There's a moving angle piece with a hole in each flange. The bottom flange has a nut welded on so the bolt/washer can be screwed in from underneath and this fixes the angle to the 'bed' while still allowing movement. The hole in the upright is slightly bigger than the head of the smaller screws. This hole had a washed welded over it on the side nearest the long thread, then the screw was fed through and welded to the end of the long thread.

This allows the long thread to turn as it pushes/pulls the angle along the bed and also allows a slight sideways movement of the angle to compensate for any uneven pieces clamped in the jaws.

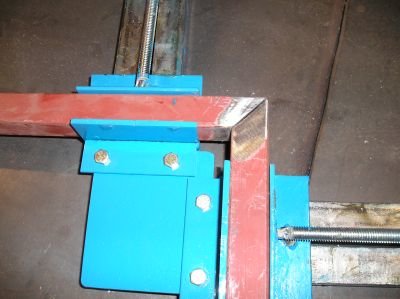

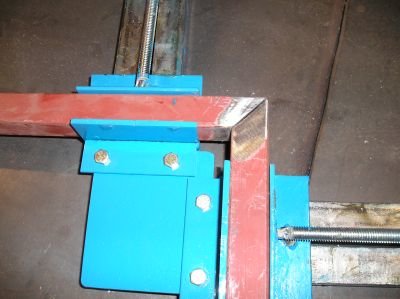

Photo 3 shows the finished clamps. I've welded some 20mm box on the end of the thread as a handle.

On the tail-stops I added small sections of angle with holes and cut some 5mm plate with holes to clamp the whole thing together. I decided on bolts as I didn't want to risk it being off 90 degrees due to welding and also I may want to disassemble these in the future if I need drill clamps, etc.

Finally I painted them and put a plastic blanking plug in the handle, then set the angle at 90 degrees. I left the top of the bed unpainted and put a smear of grease on it to allow smoother operation.

Here's the first job I did with the tool...it's a rectangle of 25mm box about 50" x 14" and I was pleased to find that with 45 degree cuts in the chop-saw everything lined up perfectly on the last angle with no bending required to make it fit!

Regards

Peter

for years I've had a couple of pieces of angle welded at approx 90 degrees, the angle drifted out as the weld cooled, and I've been thinking of repacing that as it was tricky to use. I was looking at a set of these 90 degree clamps a week or two back but decided they looked a bit too flimsy for me (they were cheap), so I thought I'd have a go at making some.

Here's the basic materials for two clamps...

In the photo, the vertical angle will be welded to the flat plates, one with a hole to have a nut welded over it to take the long thread and the other plate is the tail-stop.

Photo 2 shows the slider parts. There's a moving angle piece with a hole in each flange. The bottom flange has a nut welded on so the bolt/washer can be screwed in from underneath and this fixes the angle to the 'bed' while still allowing movement. The hole in the upright is slightly bigger than the head of the smaller screws. This hole had a washed welded over it on the side nearest the long thread, then the screw was fed through and welded to the end of the long thread.

This allows the long thread to turn as it pushes/pulls the angle along the bed and also allows a slight sideways movement of the angle to compensate for any uneven pieces clamped in the jaws.

Photo 3 shows the finished clamps. I've welded some 20mm box on the end of the thread as a handle.

On the tail-stops I added small sections of angle with holes and cut some 5mm plate with holes to clamp the whole thing together. I decided on bolts as I didn't want to risk it being off 90 degrees due to welding and also I may want to disassemble these in the future if I need drill clamps, etc.

Finally I painted them and put a plastic blanking plug in the handle, then set the angle at 90 degrees. I left the top of the bed unpainted and put a smear of grease on it to allow smoother operation.

Here's the first job I did with the tool...it's a rectangle of 25mm box about 50" x 14" and I was pleased to find that with 45 degree cuts in the chop-saw everything lined up perfectly on the last angle with no bending required to make it fit!

Regards

Peter