Hi,

Since it was this forum which confirmed my suspicions and suggested a few mods might be in order, I thought I'd share what I've done so far.

Wire feed:

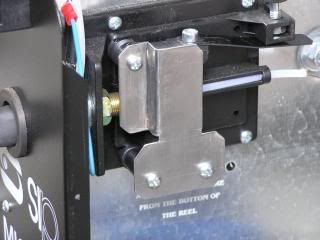

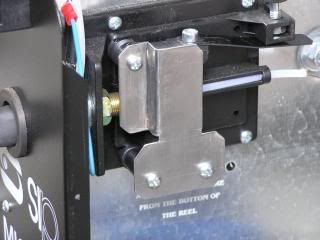

I swivelled the spring out from under the adjuster and pressed it while watching what happened. As I noticed that the lower drive roller support moved as well as the upper one, I made this brace which stops both roller supports moving almost completely. It's a bit more complicated than the brace I've seen others using but I was bored, it was raining and I couldn't work on the car and I have an ever-so slight tendency to over-engineer just a touch...

The other thing... I'd seen a few pics of liner and thought, "I've seen something like that somewhere before." Then it dawned on me.

Curtain wire!

It's the same diameter as the original PVC liner, it fits, it's springy, I had some already, friction is massively reduced over the PVC liner and I can buy a 3m length from the local supermarket for 59p... Seems worth a try

I can now tie a 10" knot in the torch cord and it'll still feed on the slowest setting with the feed roller pressure as low as it will go. A huge improvement; wire feed was highly erratic beforehand and it was driving me nuts!

Doubtless I'll come up with more; the electronics-related bits of my brain are already pondering a way of stabilising the drive to the wire-feed motor while keeping the 'automatic' rough speed selection and avoiding use of an extra transformer. I'll keep quiet about that until I've finished blowing power transistors up and have something figured out which works.

Since it was this forum which confirmed my suspicions and suggested a few mods might be in order, I thought I'd share what I've done so far.

Wire feed:

I swivelled the spring out from under the adjuster and pressed it while watching what happened. As I noticed that the lower drive roller support moved as well as the upper one, I made this brace which stops both roller supports moving almost completely. It's a bit more complicated than the brace I've seen others using but I was bored, it was raining and I couldn't work on the car and I have an ever-so slight tendency to over-engineer just a touch...

The other thing... I'd seen a few pics of liner and thought, "I've seen something like that somewhere before." Then it dawned on me.

Curtain wire!

It's the same diameter as the original PVC liner, it fits, it's springy, I had some already, friction is massively reduced over the PVC liner and I can buy a 3m length from the local supermarket for 59p... Seems worth a try

I can now tie a 10" knot in the torch cord and it'll still feed on the slowest setting with the feed roller pressure as low as it will go. A huge improvement; wire feed was highly erratic beforehand and it was driving me nuts!

Doubtless I'll come up with more; the electronics-related bits of my brain are already pondering a way of stabilising the drive to the wire-feed motor while keeping the 'automatic' rough speed selection and avoiding use of an extra transformer. I'll keep quiet about that until I've finished blowing power transistors up and have something figured out which works.