knoba

...break a leg!

- Messages

- 863

- Location

- Sussex, England

I read a thread on this forum, started by malcolm, about joining two tubes together and then hitch came up with his method. These blocks were inspired by that thread.

They're not extremely accurate, but good enough for what I wanted them for.

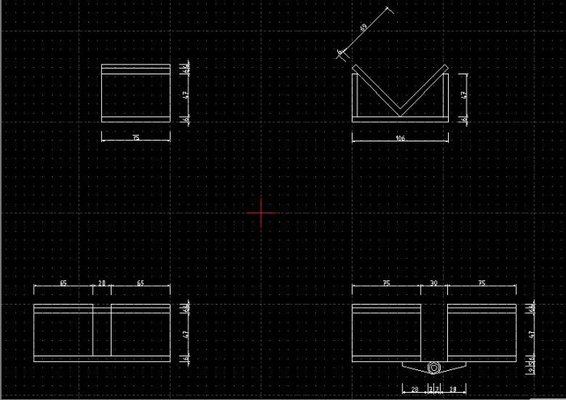

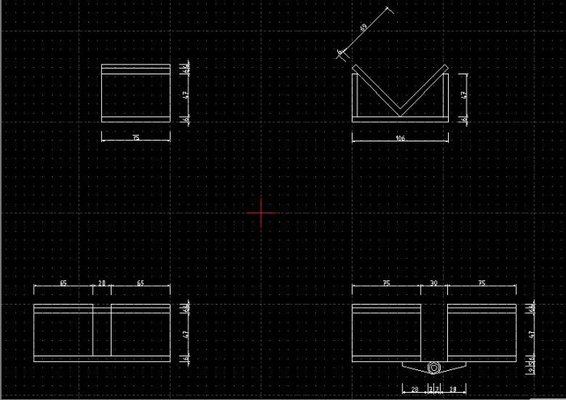

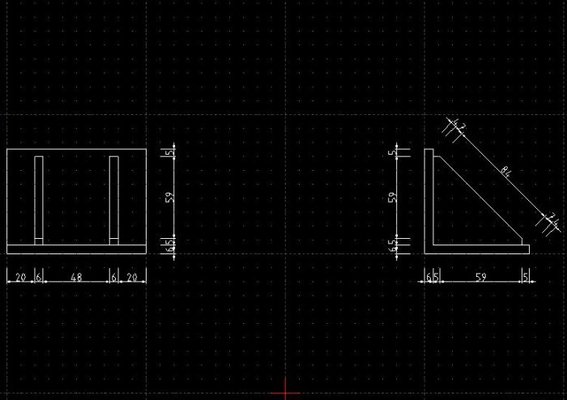

CAD allows me to draw only the views that are useful, to me, to make them. The lower two variations are; left - straight pipe welder & right - adjustable angle pipe welder/setter. They could easily be made at the same time as the 'v' blocks.

When metal working I wear an Esab full grain leather apron & no-name rigger gloves. When angle grinding I have pulsafe full ear defenders and a brow guard from screwfix. (it's not a pretty sight, believe me, but safety is important)

My working area is clean and free of obstacles (own self & bike excluded).

I cut 4 x 100mm of hot rolled, mild steel, equal angle (EA) @ 6mm x 75mm x 75mm. Each piece was marked square and cut with a 125mm angle grinder. And the same again for 4 x 100mm of hot rolled, mild steel, flat section (FS) @ 6mm x 100mm.

I drilled M10 holes in the base plates (the holing could be v. useful in the future and are much easier to do now.).

The centres of the base plates are marked and I set up the assemblies, in pairs, so that they are as true as possible, with a flat heavy weight on top, while I tack them with the MIG. (If the metal wasn't new and rust less I would have cleaned it, carefully, with a twisted knot wire brush on an 125mm angle grinder.)

I clamped the assemblies to a thick & strong piece of steel to stop them warping and to draw away heat from them. 3 MIG tacks down each side should be ample for strength without heat distorting the symetry of the blocks.

The ends are, finally, cleaned up with a flap disc on a 125mm variable speed angle grinder and the the welds are cleaned with a thin hand wire brush.

After that, they're thoroughly cleaned. Painted on all non-used faces and waxed (Colron finishing wax) on used faces. They can be used to set up jobs in this manner;

Material cost - about £1 each block.

Little tools that do a great job. I couldn't have done such a good job on my Tig trolley without them. My Thanks to all!

They're not extremely accurate, but good enough for what I wanted them for.

CAD allows me to draw only the views that are useful, to me, to make them. The lower two variations are; left - straight pipe welder & right - adjustable angle pipe welder/setter. They could easily be made at the same time as the 'v' blocks.

When metal working I wear an Esab full grain leather apron & no-name rigger gloves. When angle grinding I have pulsafe full ear defenders and a brow guard from screwfix. (it's not a pretty sight, believe me, but safety is important)

My working area is clean and free of obstacles (own self & bike excluded).

I cut 4 x 100mm of hot rolled, mild steel, equal angle (EA) @ 6mm x 75mm x 75mm. Each piece was marked square and cut with a 125mm angle grinder. And the same again for 4 x 100mm of hot rolled, mild steel, flat section (FS) @ 6mm x 100mm.

I drilled M10 holes in the base plates (the holing could be v. useful in the future and are much easier to do now.).

The centres of the base plates are marked and I set up the assemblies, in pairs, so that they are as true as possible, with a flat heavy weight on top, while I tack them with the MIG. (If the metal wasn't new and rust less I would have cleaned it, carefully, with a twisted knot wire brush on an 125mm angle grinder.)

I clamped the assemblies to a thick & strong piece of steel to stop them warping and to draw away heat from them. 3 MIG tacks down each side should be ample for strength without heat distorting the symetry of the blocks.

The ends are, finally, cleaned up with a flap disc on a 125mm variable speed angle grinder and the the welds are cleaned with a thin hand wire brush.

After that, they're thoroughly cleaned. Painted on all non-used faces and waxed (Colron finishing wax) on used faces. They can be used to set up jobs in this manner;

Material cost - about £1 each block.

Little tools that do a great job. I couldn't have done such a good job on my Tig trolley without them. My Thanks to all!

)

)

They drastically reduced the price rather than have it all back.

They drastically reduced the price rather than have it all back.