I did a little demo to illustrate the effect arc length has for someone struggling with a fillet weld recently. Thought it may be helpful for anyone new to TIG...

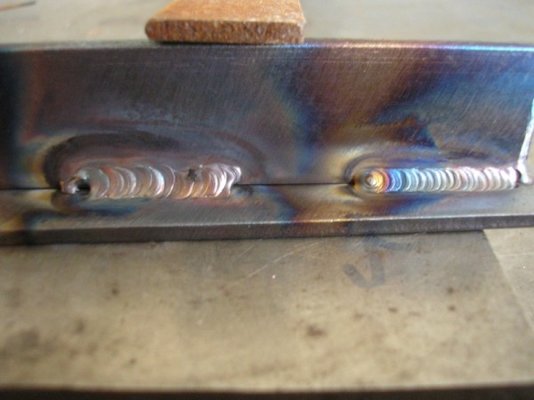

3mm mild steel, 100A, 1 sec slope down, 5L/min argon with a #7 gas lens. After tacking the bits together i added a couple of autogenous tacks using different arc lengths- on the right arc length around 1 - 2mm, on the left had around 5 - 6mm arc length. Too far away to get fusion

Ran short welds keeping the same arc lengths. With a long arc you initially get 2 puddles (unless the juice is cranked way up), adding filler fixes that but the puddle remains crescent shaped. The filler starts to melt before it reaches the puddle and tends to 'wick' towards one side or the other rather than where you aim. Obviously there is a large lack of fusion problem with the long arc weld

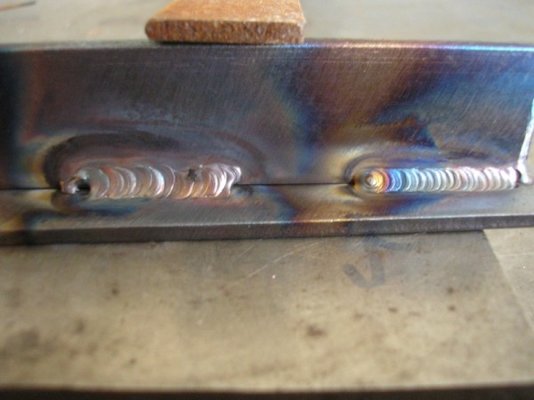

Despite staying at 100A the back of the piece (left and right obviously reversed) shows the differences in heat input

3mm mild steel, 100A, 1 sec slope down, 5L/min argon with a #7 gas lens. After tacking the bits together i added a couple of autogenous tacks using different arc lengths- on the right arc length around 1 - 2mm, on the left had around 5 - 6mm arc length. Too far away to get fusion

Ran short welds keeping the same arc lengths. With a long arc you initially get 2 puddles (unless the juice is cranked way up), adding filler fixes that but the puddle remains crescent shaped. The filler starts to melt before it reaches the puddle and tends to 'wick' towards one side or the other rather than where you aim. Obviously there is a large lack of fusion problem with the long arc weld

Despite staying at 100A the back of the piece (left and right obviously reversed) shows the differences in heat input

, the one on the left looks pretty much like mine at the mo

, the one on the left looks pretty much like mine at the mo  .

. can be a real pain in the harris my eyes seem to zoom in and out all the time, have to really concentrate on focusing....

can be a real pain in the harris my eyes seem to zoom in and out all the time, have to really concentrate on focusing.... any one else have similar isssues...

any one else have similar isssues...