BChild

SIP - enough with the mods!!!!

- Messages

- 1,023

Hi All

been lurking for a while and picked up a fair bit of information but I haven't found the answers to all my questions or issues although what I have found has certainly been usefull

I'd better give some background first

I bought a Cosmo 170 a while back (we are talking years not months) and it hasn't seen much use - doing the odd plug weld to fix a bracket on my track car and a small patch in the floor to fix a water leak - none of them pretty and thats about the limit of my abilities and apparently this shonky welder!!

and thats about the limit of my abilities and apparently this shonky welder!!

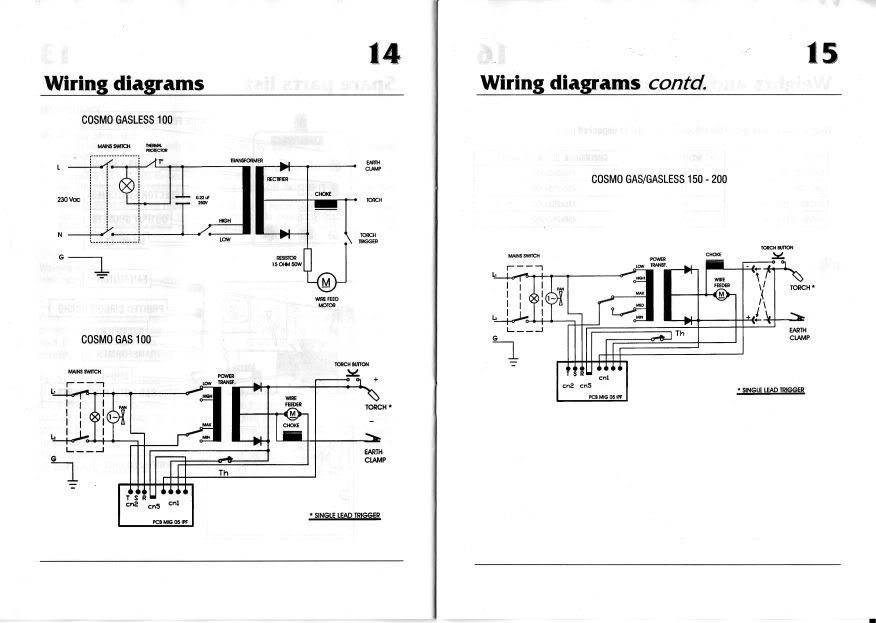

However I've ended up with a bigger task (a mini that needs new sills) and to be frank I'm struggling to get to grips with this welder - it might not help that I've lost the original instruction booklet but from memory when I read it from cover to cover it didn't seem like much help so is probably filed somewhere never to be seen again - I'll try to contact COSMO andsee if I can get another copy as advised elswhere on another thread

Anyway enough dribble - I have a welder that has

- rubbish wire feed (and it certainly is) but there is a fix detailed on here) so first job tommorrow is to do that - slips like crazy and the rollers are way out of line

- doesn't like gassless wire bunches it up after the feeder

- makes bigger holes in things when trying to join metal or has little or no penetration and the wire feed settings and power settings are a lottery to me it seems

So first question

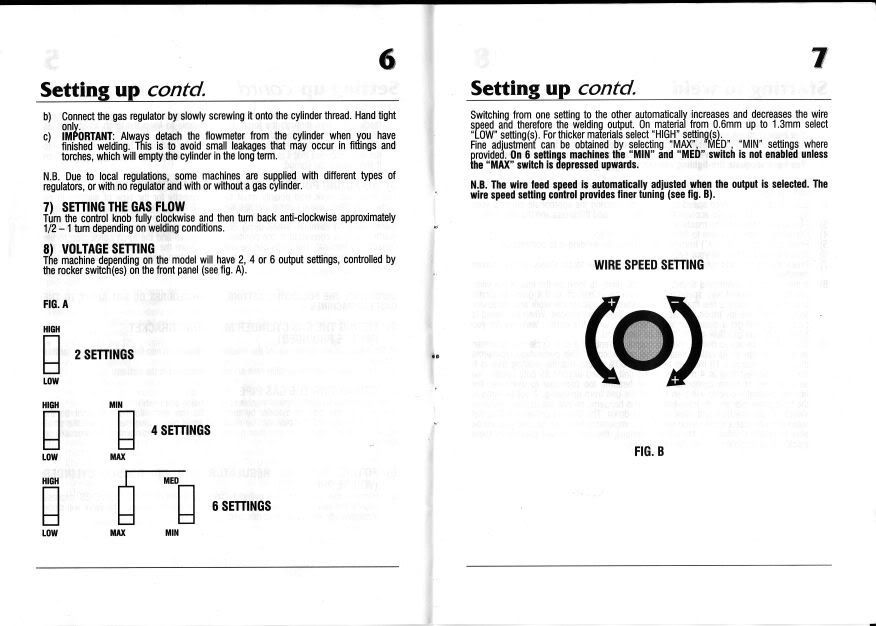

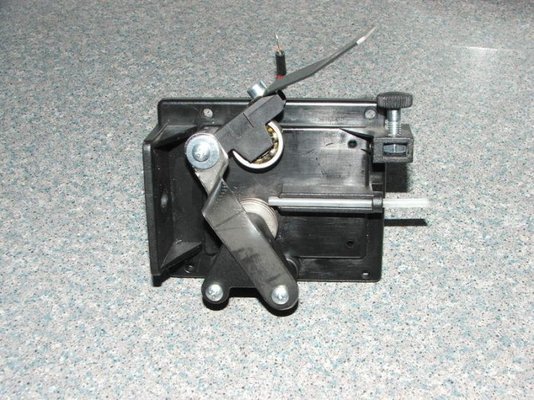

On the front of the welder there are a series of power switches

I may be being a bit thick here but can anyone help with the sequence of switch positions from lowest to highest power output?

I know that on this welder the power settings also make crude changes to the wire feed speed but the wire feed adjuster pot can be trimmed accordingly

Second question

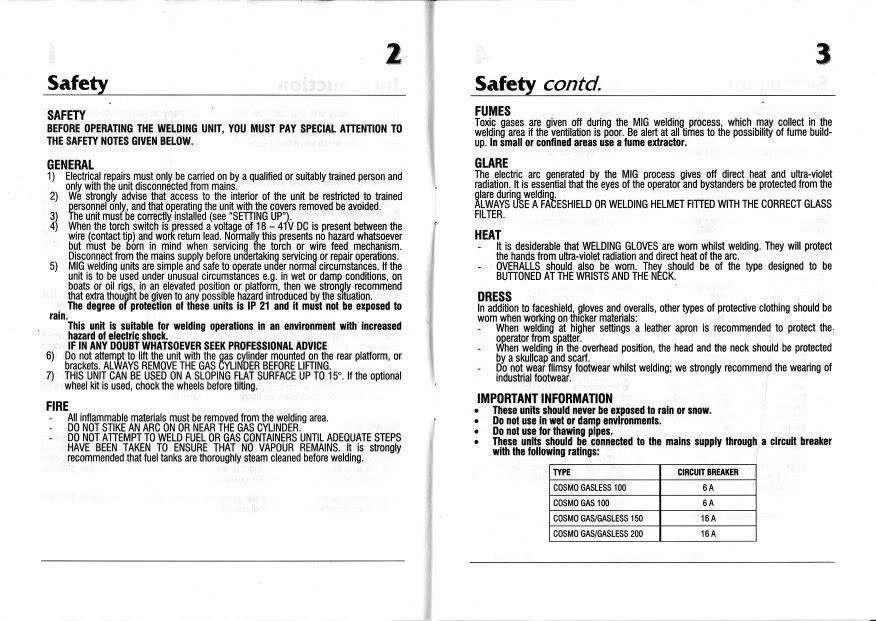

Reading up on this site it seems that polarity is important can someone explain firstly why and secondly what polarity should it be for normal wire as opposed to the gassless stuff

Third question and probably a more basic one

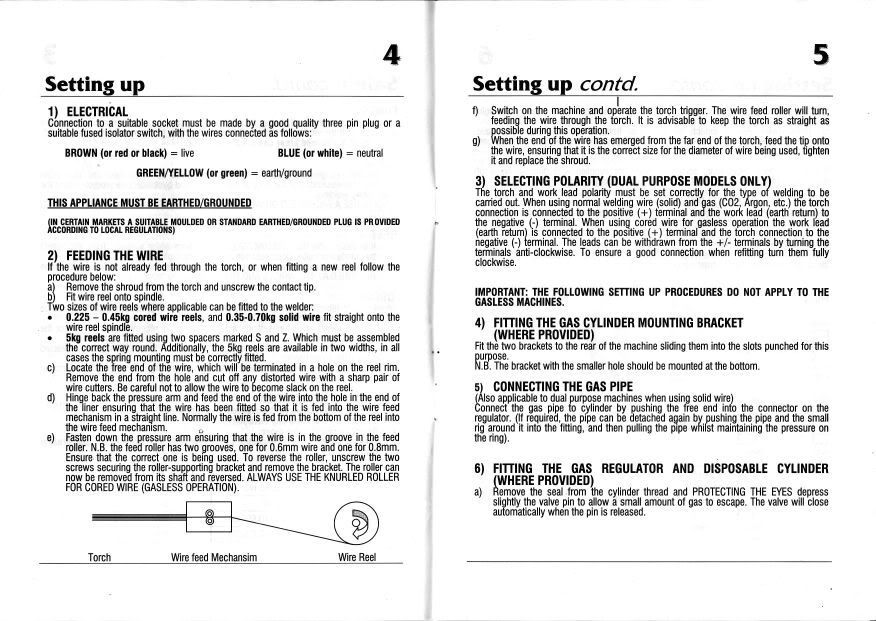

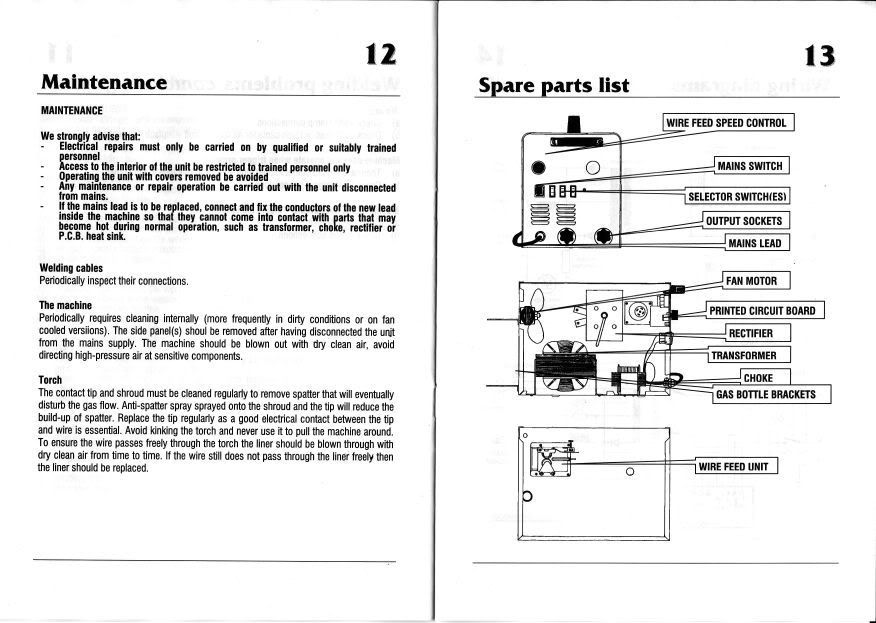

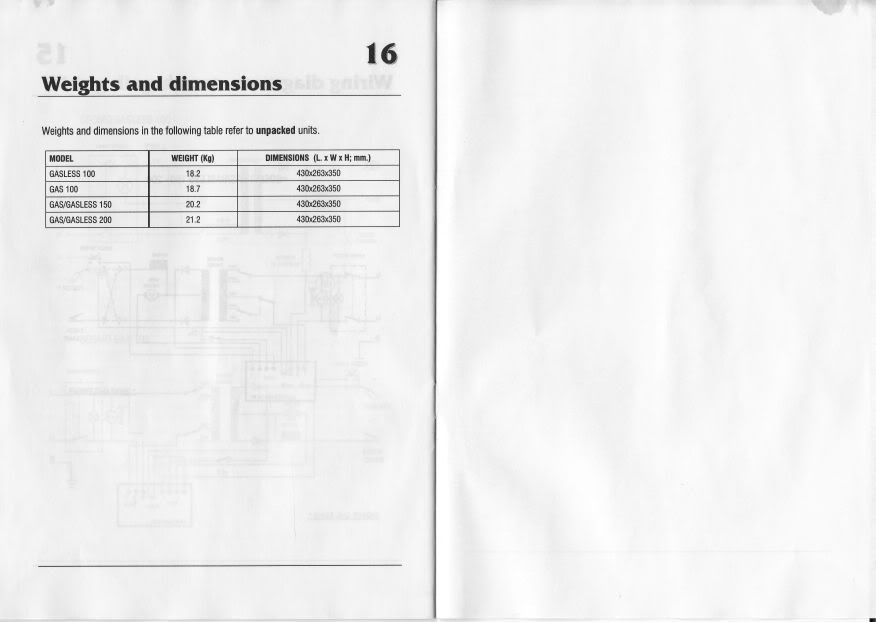

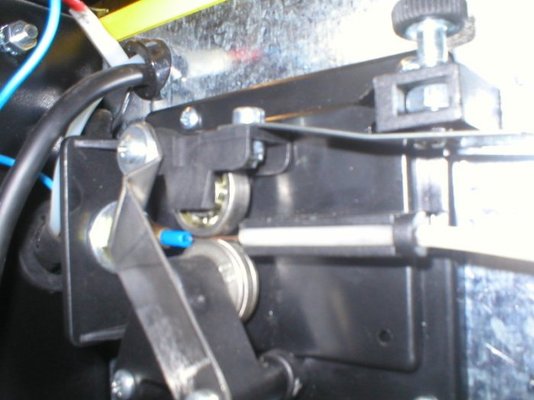

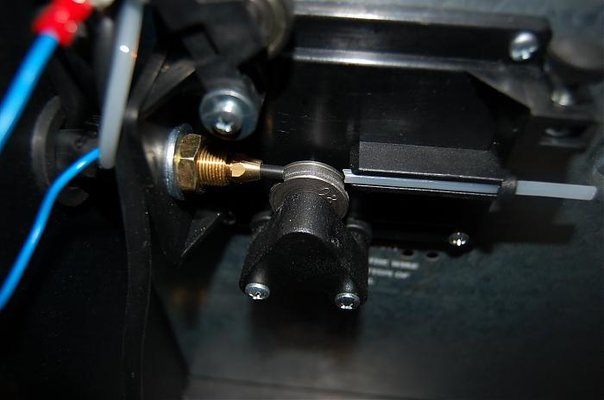

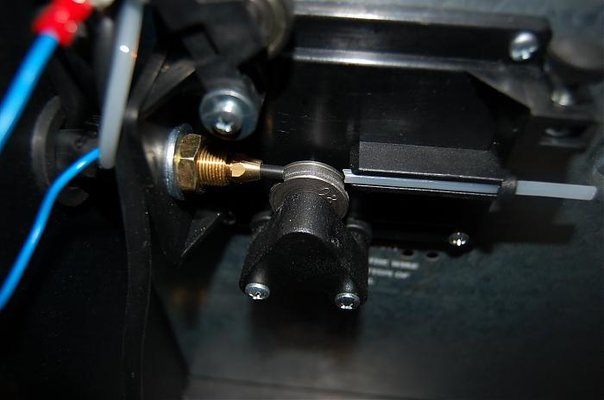

I spotted this picture

And thought oooh now thats different to mine - the liner comes almost to the wire feeder on this picture and I can't even see the liner on mine - this may acount for the poor performance of gassless wire

Anyway thanks in advance for any clues

Regards

Ian

been lurking for a while and picked up a fair bit of information but I haven't found the answers to all my questions or issues although what I have found has certainly been usefull

I'd better give some background first

I bought a Cosmo 170 a while back (we are talking years not months) and it hasn't seen much use - doing the odd plug weld to fix a bracket on my track car and a small patch in the floor to fix a water leak - none of them pretty

However I've ended up with a bigger task (a mini that needs new sills) and to be frank I'm struggling to get to grips with this welder - it might not help that I've lost the original instruction booklet but from memory when I read it from cover to cover it didn't seem like much help so is probably filed somewhere never to be seen again - I'll try to contact COSMO andsee if I can get another copy as advised elswhere on another thread

Anyway enough dribble - I have a welder that has

- rubbish wire feed (and it certainly is) but there is a fix detailed on here) so first job tommorrow is to do that - slips like crazy and the rollers are way out of line

- doesn't like gassless wire bunches it up after the feeder

- makes bigger holes in things when trying to join metal or has little or no penetration and the wire feed settings and power settings are a lottery to me it seems

So first question

On the front of the welder there are a series of power switches

I may be being a bit thick here but can anyone help with the sequence of switch positions from lowest to highest power output?

I know that on this welder the power settings also make crude changes to the wire feed speed but the wire feed adjuster pot can be trimmed accordingly

Second question

Reading up on this site it seems that polarity is important can someone explain firstly why and secondly what polarity should it be for normal wire as opposed to the gassless stuff

Third question and probably a more basic one

I spotted this picture

And thought oooh now thats different to mine - the liner comes almost to the wire feeder on this picture and I can't even see the liner on mine - this may acount for the poor performance of gassless wire

Anyway thanks in advance for any clues

Regards

Ian

Last edited by a moderator: