Porschemaniac

Member

- Messages

- 305

Firstly, a big thank you to Malcolm, not only for this site - but also for sewing the seed of this idea in my head.

Having recently purchased a new Clarke compressor (2.5 HP, 50 Litre and 8.7 CFM) I had planned to put the old one on e-bay.

After finding the new compressor still somewhat lacking in the power department, and after consulting the fine fellows on this forum, I decided that, rather than get £40 or so, for the old one on the Bay of e, I would plumb them together.

Well, after a trip to Screwfix for copious amounts of compression fittings and PTFE tape, I finally set to plumbing them together this afternoon.

As jobs go, it went swimmingly - all joints gas tight first time (mind you, they should be, with all that tape around them ).

).

The basic setup is shown here:

Kind of following Malcolm's guide, I have plumbed the two into one common drop leg, both independently controlled by a Ball Valve, with a Ball Valve at the bottom of the leg, to allow for drainage.

The drop leg makes it's way up, through the workbench and into a combined filter / regulator / lubricator:

I must confess, that I haven't tested at full pressure (8 Bar) yet, but all is gas-tight at 6 (ish) Bar.

All that remains now is to set the smaller compressor to cut in at a slightly lower pressure than the big one - and, here, I could really use some more help.

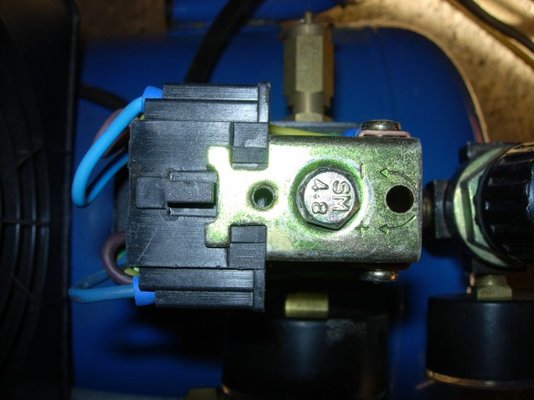

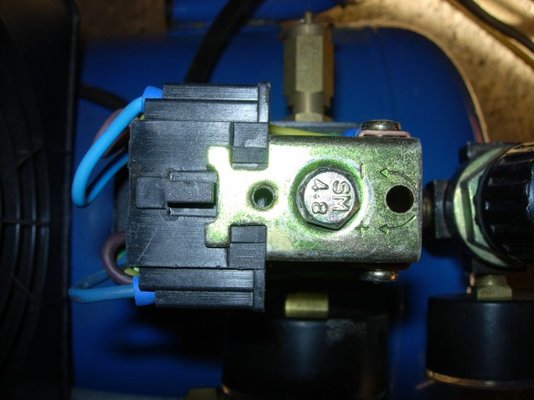

The pressure switch on the smaller unit looks like this:

Now, I'm guessing that this type of switch has a pre-set (and unchangeable) upper cut off (8 Bar, in this case). So, it follows that the adjuster must alter the lower cut off? Can anyone give me some guidance on this.

I'm guessing that I only need a marginal difference between the cut-in pressures (1 Bar, or so?) Again, guidance will be gratefully received.

All in all, I reckon this was a Sunday afternoon well spent; theoretically, it now gives 15.7 CFM and 74 Litres, from a combined 4HP!

If you have an old compressor, which you are thinking of upgrading, I really think that putting the two to use together is the way forward.

Having recently purchased a new Clarke compressor (2.5 HP, 50 Litre and 8.7 CFM) I had planned to put the old one on e-bay.

After finding the new compressor still somewhat lacking in the power department, and after consulting the fine fellows on this forum, I decided that, rather than get £40 or so, for the old one on the Bay of e, I would plumb them together.

Well, after a trip to Screwfix for copious amounts of compression fittings and PTFE tape, I finally set to plumbing them together this afternoon.

As jobs go, it went swimmingly - all joints gas tight first time (mind you, they should be, with all that tape around them

The basic setup is shown here:

Kind of following Malcolm's guide, I have plumbed the two into one common drop leg, both independently controlled by a Ball Valve, with a Ball Valve at the bottom of the leg, to allow for drainage.

The drop leg makes it's way up, through the workbench and into a combined filter / regulator / lubricator:

I must confess, that I haven't tested at full pressure (8 Bar) yet, but all is gas-tight at 6 (ish) Bar.

All that remains now is to set the smaller compressor to cut in at a slightly lower pressure than the big one - and, here, I could really use some more help.

The pressure switch on the smaller unit looks like this:

Now, I'm guessing that this type of switch has a pre-set (and unchangeable) upper cut off (8 Bar, in this case). So, it follows that the adjuster must alter the lower cut off? Can anyone give me some guidance on this.

I'm guessing that I only need a marginal difference between the cut-in pressures (1 Bar, or so?) Again, guidance will be gratefully received.

All in all, I reckon this was a Sunday afternoon well spent; theoretically, it now gives 15.7 CFM and 74 Litres, from a combined 4HP!

If you have an old compressor, which you are thinking of upgrading, I really think that putting the two to use together is the way forward.