Paul.

Moderator

- Messages

- 7,052

- Location

- Northampton. UK

I know some of you like to see metal being formed up so here's a little job I did this morning, its just an extractor nozzle to fit on the outlet chute of a planer thicknesser, to connect to a vacuum extractor

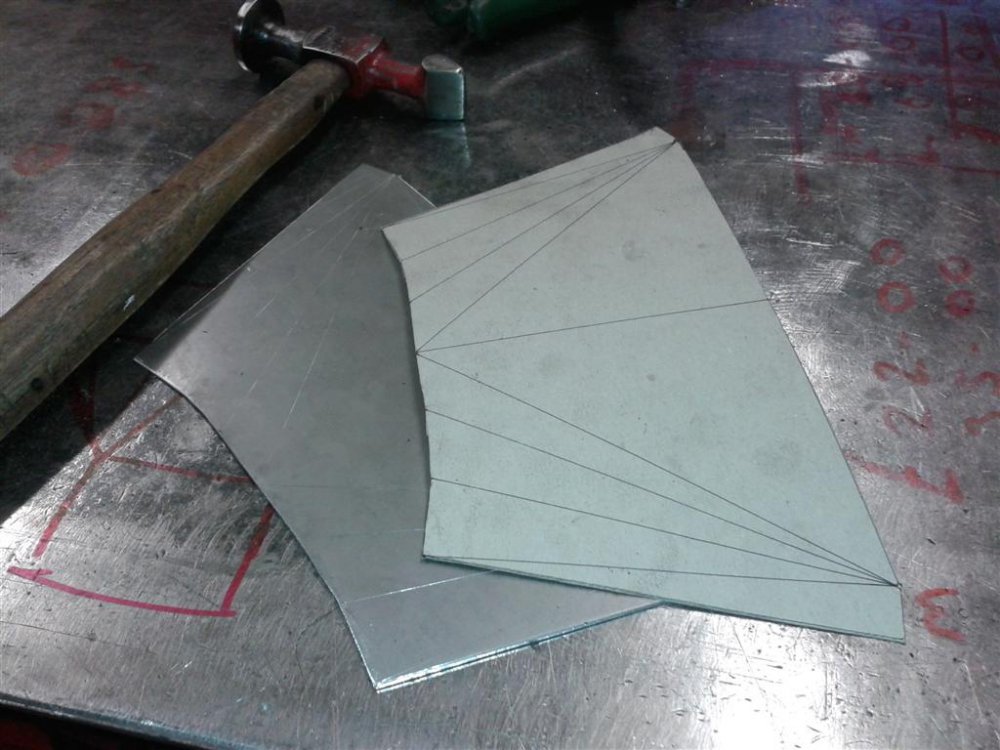

Developed it out first on cardboard, then cut it out to use as a template. material is 18swg mild steel

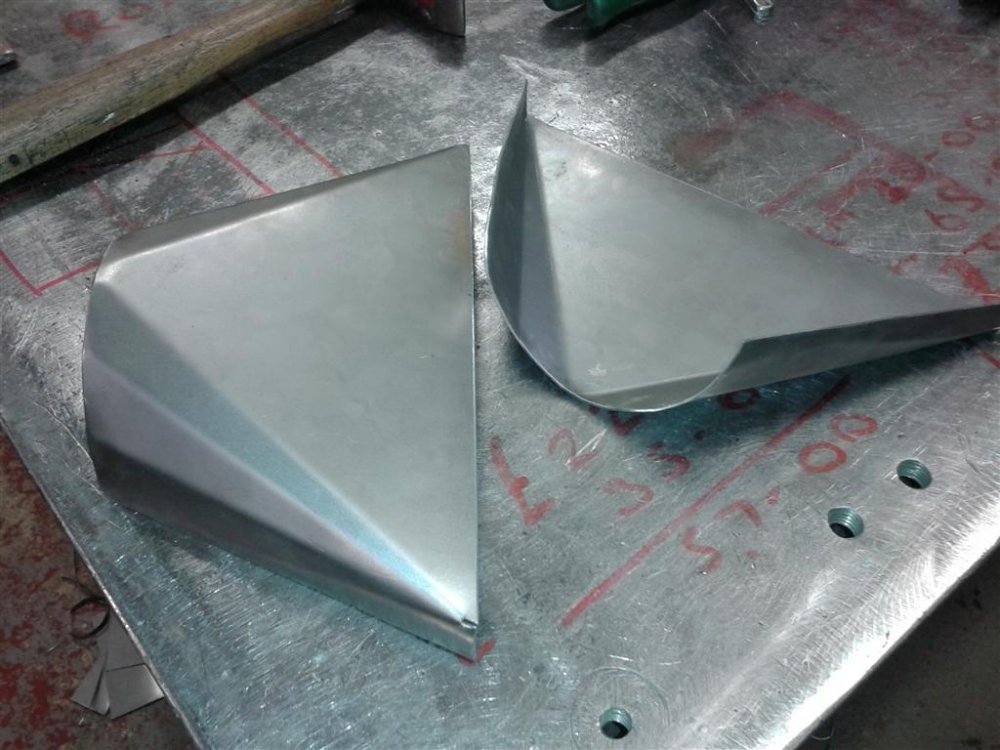

Bending it up in the flypress, note the cut in the corner it helps to keep the corner square, easy enough to weld up afterwards.

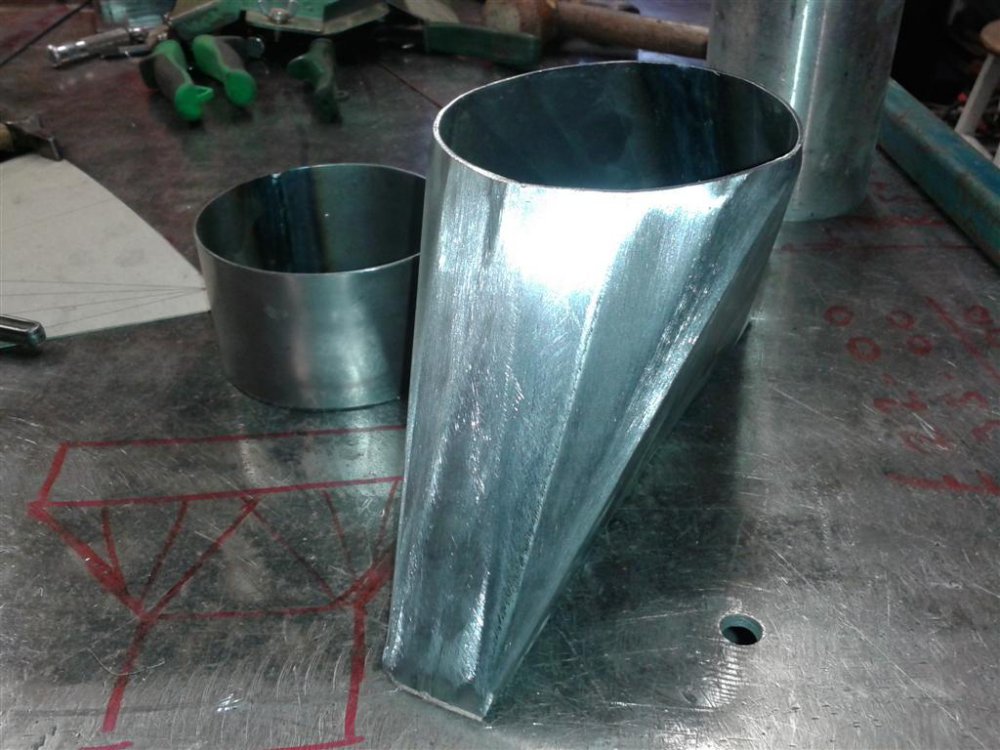

Tigged up and welds cleaned off, and rolled a ring for the vacuum hose, also dressed out the flats to make a nice circle and a good fit up to the ring.

Fully welded here

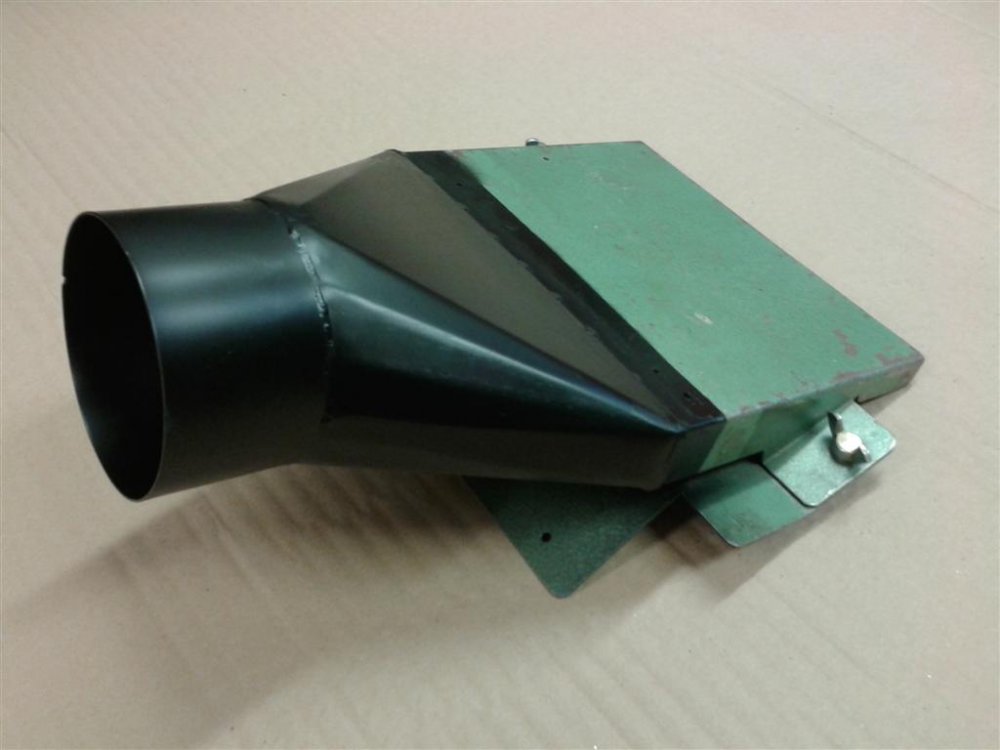

A few mig tacks to hold it to the existing chute, it doesn't need to be fully welded.

And a coat of paint finishes it off, I can do any colour you like as long as its black.

Developed it out first on cardboard, then cut it out to use as a template. material is 18swg mild steel

Bending it up in the flypress, note the cut in the corner it helps to keep the corner square, easy enough to weld up afterwards.

Tigged up and welds cleaned off, and rolled a ring for the vacuum hose, also dressed out the flats to make a nice circle and a good fit up to the ring.

Fully welded here

A few mig tacks to hold it to the existing chute, it doesn't need to be fully welded.

And a coat of paint finishes it off, I can do any colour you like as long as its black.