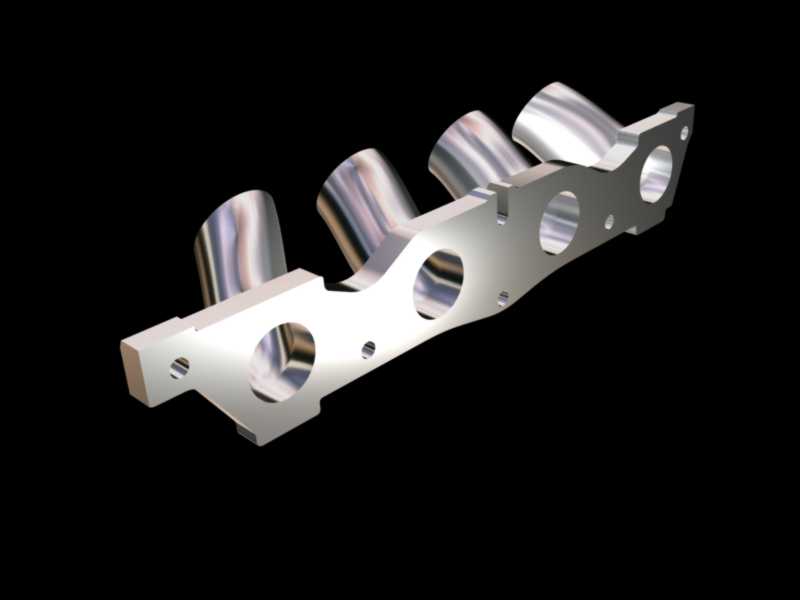

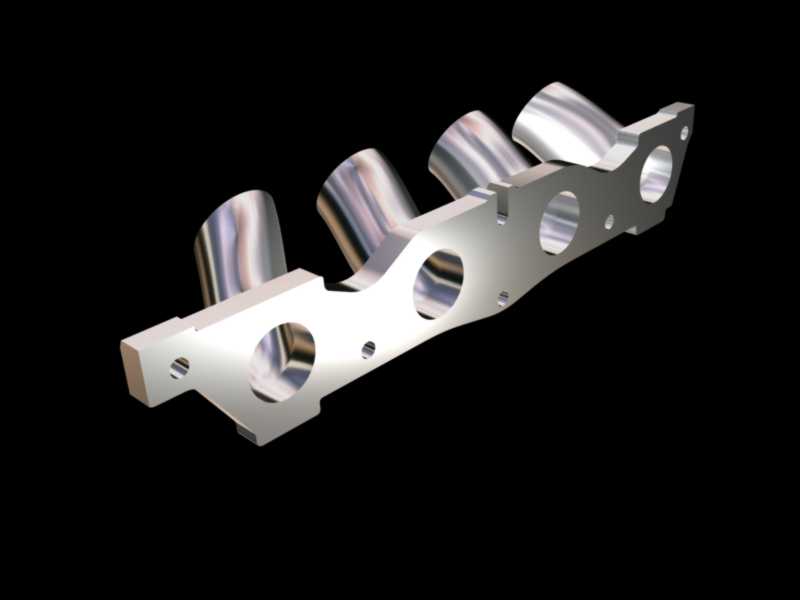

Alright here's one for you....I'm trying to fit a set of motor bike carbs to my Pinto engine kitcar and I've got my manifold designed. Now I've got the tough job of trying to make the thing! I've got some Aluminium pipe 4mm wall, 38 mm I/diameter, and I'm gonna mill up some plates to fit the pipe to. However whats the best way to join the pipe and plate? I've tried welding with aluminium wire and not had much success so I'm inclined to avoid this method! Would I be able to braze aluminium? or has anyone any experience with these sort of Ali brazing rods? Also on a related note I'm about to setup a BOC account for welding gas, what should I get. I'll prob mostly be doing mild steel, chassis and bodywork, though I'm gonna be doing alot of stainless work and aluminium/brazing (hopefully!) What are the disadvantages of having a 100% Argon gas shield?? I wont be welding thick steel prob 2-3 mm max....Or can I use a low 5% CO2 mix and still weld ali and stainless still??? Can't afford 2 bottles unfortunately, and little bottles are proving far too pricey! Thanks...Oli.

Last edited by a moderator: