vanagon nut

Vanagon Nut

- Messages

- 44

Hi all.

This is for 2" aftermarket pipe and flanges.

Bought 4 flanges, same PN (Walker). 2 fit nicely on pipe and welded fine (un-tested though) 2 had an obviously larger ID.

Is it a general "rule" that a given exhaust flange will actually measure larger than it's stated size? i.e. 2-1/8" for 2" ID flange? (root gap?)

I've welded a few formed (thicker plate) flanges that had the same (nearly) ID as OD of pipe. Welds held up fine.

In image #2, would this idea produce a weak join?

Much thanks,

Neil.

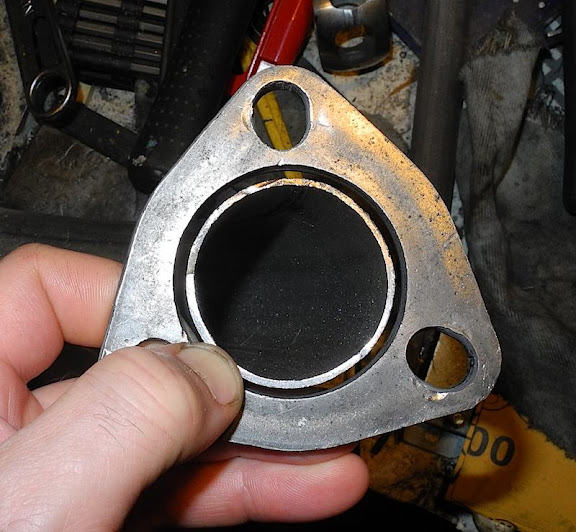

Walker " 2" " ID flange on actual 2" OD pipe:

Weld inside/outside of sleeve to pipe then flange to that? Structurally sound? (ignore gap on sleeve. It's a cut piece of 2" pipe)

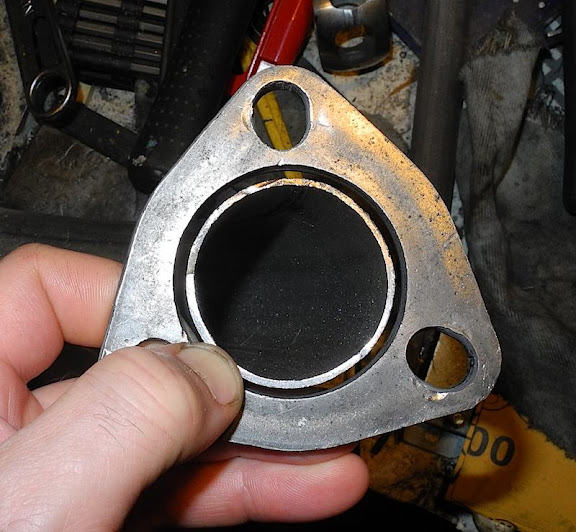

Actual 2" ID flanges on cat. Welds look ok. .... to my amateur eye.

This is for 2" aftermarket pipe and flanges.

Bought 4 flanges, same PN (Walker). 2 fit nicely on pipe and welded fine (un-tested though) 2 had an obviously larger ID.

Is it a general "rule" that a given exhaust flange will actually measure larger than it's stated size? i.e. 2-1/8" for 2" ID flange? (root gap?)

I've welded a few formed (thicker plate) flanges that had the same (nearly) ID as OD of pipe. Welds held up fine.

In image #2, would this idea produce a weak join?

Much thanks,

Neil.

Walker " 2" " ID flange on actual 2" OD pipe:

Weld inside/outside of sleeve to pipe then flange to that? Structurally sound? (ignore gap on sleeve. It's a cut piece of 2" pipe)

Actual 2" ID flanges on cat. Welds look ok. .... to my amateur eye.