First of all,apologies to the MODs, it's my first post and I know it's in the wrong place but I couldn't find a suitable one under welding machines so put it here in the hope you'll move it rather than delete.

My "Giant" is the same machine as many Chinese offerings under different names, and I know they are treated with distain by serious welders, but for hobbyists like me, they open up real possibilities. I fabricate a lot of different parts for classic racing motorcycles and this machine has served me well for over two years now. I wouldn't call myself a professional welder, but I was trained in the art of TIG welding mild steel, stainless and aluminium by the RAF many years ago so I'm not a complete novice either.

My reason for joining this forum, and why I'm writing this now, is because although my welder works well enough with the amps set on the machine, in both AC and DC, the pedal would do no more than act as a switch. If I flicked the switch to bring in the pot in the footpedal all I got was full power; which tends to blow holes in everything. I spent hours looking for information on why this might be as the Chinese instructions might as well have been written in, well, Chinese! Eventually I got to the bottom of the problem without blowing the machine up in the process so thought I'd share what I'd learned in the hope I might save someone else some pain.

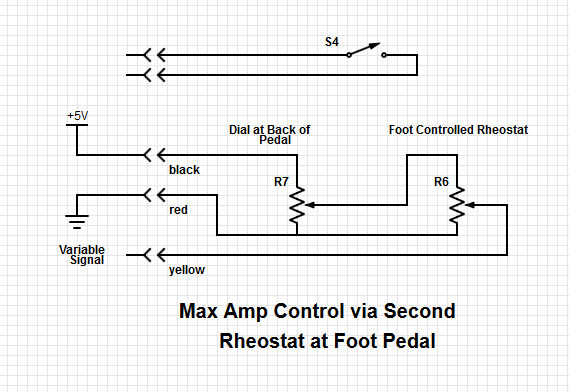

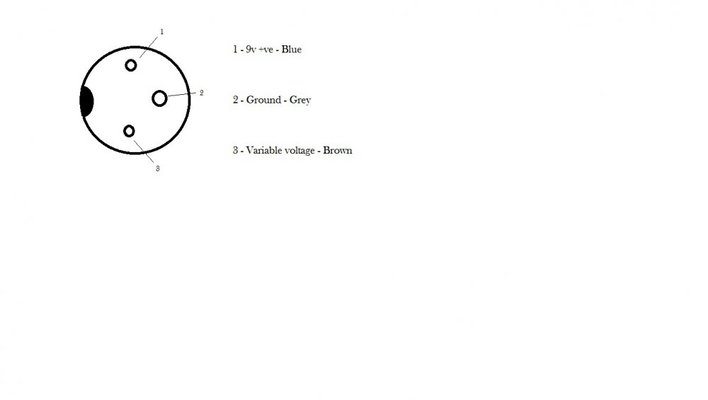

The short story is the pedal was wired correctly, but the connections at the three pin plug where wrong. The wiring is as per the most common 2 plug (2 pin 3 pin) pedal configuration in the second photo. The three-pin socket on the MACHINE is wired as photo three.

Hope that helps, John W

My "Giant" is the same machine as many Chinese offerings under different names, and I know they are treated with distain by serious welders, but for hobbyists like me, they open up real possibilities. I fabricate a lot of different parts for classic racing motorcycles and this machine has served me well for over two years now. I wouldn't call myself a professional welder, but I was trained in the art of TIG welding mild steel, stainless and aluminium by the RAF many years ago so I'm not a complete novice either.

My reason for joining this forum, and why I'm writing this now, is because although my welder works well enough with the amps set on the machine, in both AC and DC, the pedal would do no more than act as a switch. If I flicked the switch to bring in the pot in the footpedal all I got was full power; which tends to blow holes in everything. I spent hours looking for information on why this might be as the Chinese instructions might as well have been written in, well, Chinese! Eventually I got to the bottom of the problem without blowing the machine up in the process so thought I'd share what I'd learned in the hope I might save someone else some pain.

The short story is the pedal was wired correctly, but the connections at the three pin plug where wrong. The wiring is as per the most common 2 plug (2 pin 3 pin) pedal configuration in the second photo. The three-pin socket on the MACHINE is wired as photo three.

Hope that helps, John W