its been one of those jobs that I've been meaning to do for years, but now I've finally got round to making a new tool post for my Hobbymat MD65 lathe. Here are a few pictures taken along the way. I was originally going to make one which has the tool holder clamp about a circular post, but after I started changed my mind and use an eccentric driven plunger, after having a closer look at how normal qick change tool posts work.

the main post began life as a 60mm dia x 50mm long steel bar, and its amazing how much swarf you can create from one peice of metal

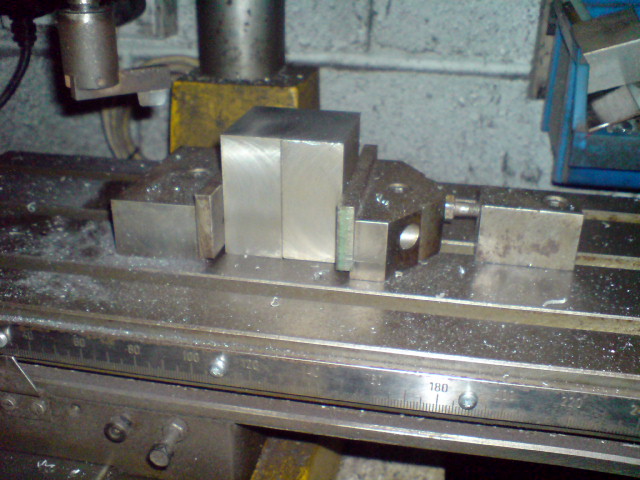

then I started making tool holders from black bar, faced up using a flycutter, in my milling machine using a vice which has jaws which bolt into the T slots, so the vice can be as long as the milling machine table

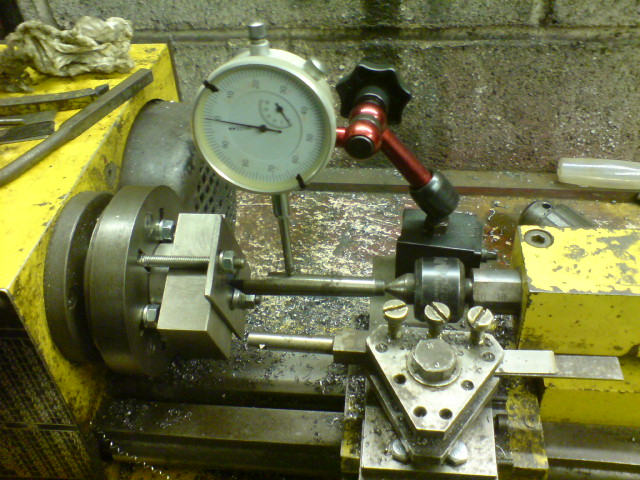

then the tool holder blank needs boring out to fit the post. the cente bore of my 4 jaw chuck was a couple of mm too small, so I needed to use a faceplate on my lathe, but as I needed to bore the centre out and not damage the faceplate, I use an outer race form an old bearing to work as circular parallel and the tool holder blank is then held in place by a metal plate. and is it is being centred on centre punched mark using a spare lathe centre and dial indicator.

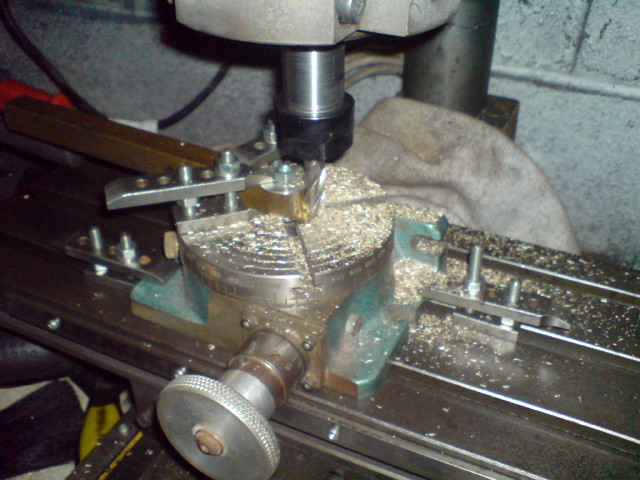

then milling the slot for the lathe tools in the tool holder

then I had a change of plan and decided to fit a a locking plunger in the tool post.

I ended up milling the end of some square brass on a rotary table to match the radius of the tool post, and lucky for me the post is 25mm diameter which is the same diameter as a 5mm penny washer, so one was used as a template. this hole was later bored out so the eccentric would work in it, and then turned in a 4 jaw chuck so that it would fit into a hole in the toolpost

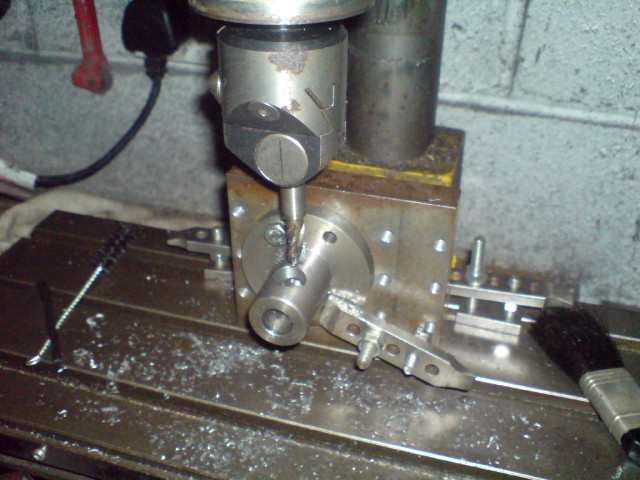

and boring a hole in the toolpost for the plunger. I didnt have a boring bar small enough do ended up using an end mill in a boring head, which ended up working pretty well

and the completed items to assemble in the toolpost. to operate the eccentric, I decided to use a M8 cap head bolt and turned it down to 6mm, and the eccentric was later loctited it to it using a high strength retainer. the eccentric is between the plunger and cap head bolt in the picture below

and how the plunger and eccentric will work in the tool post body

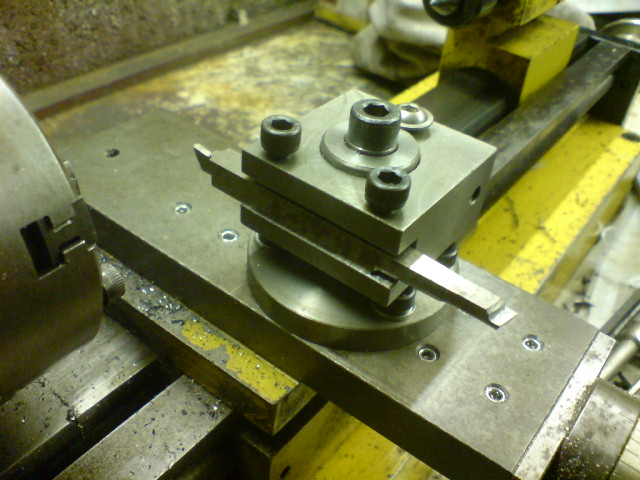

and the assembled tool post

and with a tool holder, the height is adjusted using a flange head cap screw and the tool holder is locked/ released buy using the cap head bolt on the end of the tool post.the tool holder is just under 50mm x 50mmx 25mm

the main post began life as a 60mm dia x 50mm long steel bar, and its amazing how much swarf you can create from one peice of metal

then I started making tool holders from black bar, faced up using a flycutter, in my milling machine using a vice which has jaws which bolt into the T slots, so the vice can be as long as the milling machine table

then the tool holder blank needs boring out to fit the post. the cente bore of my 4 jaw chuck was a couple of mm too small, so I needed to use a faceplate on my lathe, but as I needed to bore the centre out and not damage the faceplate, I use an outer race form an old bearing to work as circular parallel and the tool holder blank is then held in place by a metal plate. and is it is being centred on centre punched mark using a spare lathe centre and dial indicator.

then milling the slot for the lathe tools in the tool holder

then I had a change of plan and decided to fit a a locking plunger in the tool post.

I ended up milling the end of some square brass on a rotary table to match the radius of the tool post, and lucky for me the post is 25mm diameter which is the same diameter as a 5mm penny washer, so one was used as a template. this hole was later bored out so the eccentric would work in it, and then turned in a 4 jaw chuck so that it would fit into a hole in the toolpost

and boring a hole in the toolpost for the plunger. I didnt have a boring bar small enough do ended up using an end mill in a boring head, which ended up working pretty well

and the completed items to assemble in the toolpost. to operate the eccentric, I decided to use a M8 cap head bolt and turned it down to 6mm, and the eccentric was later loctited it to it using a high strength retainer. the eccentric is between the plunger and cap head bolt in the picture below

and how the plunger and eccentric will work in the tool post body

and the assembled tool post

and with a tool holder, the height is adjusted using a flange head cap screw and the tool holder is locked/ released buy using the cap head bolt on the end of the tool post.the tool holder is just under 50mm x 50mmx 25mm