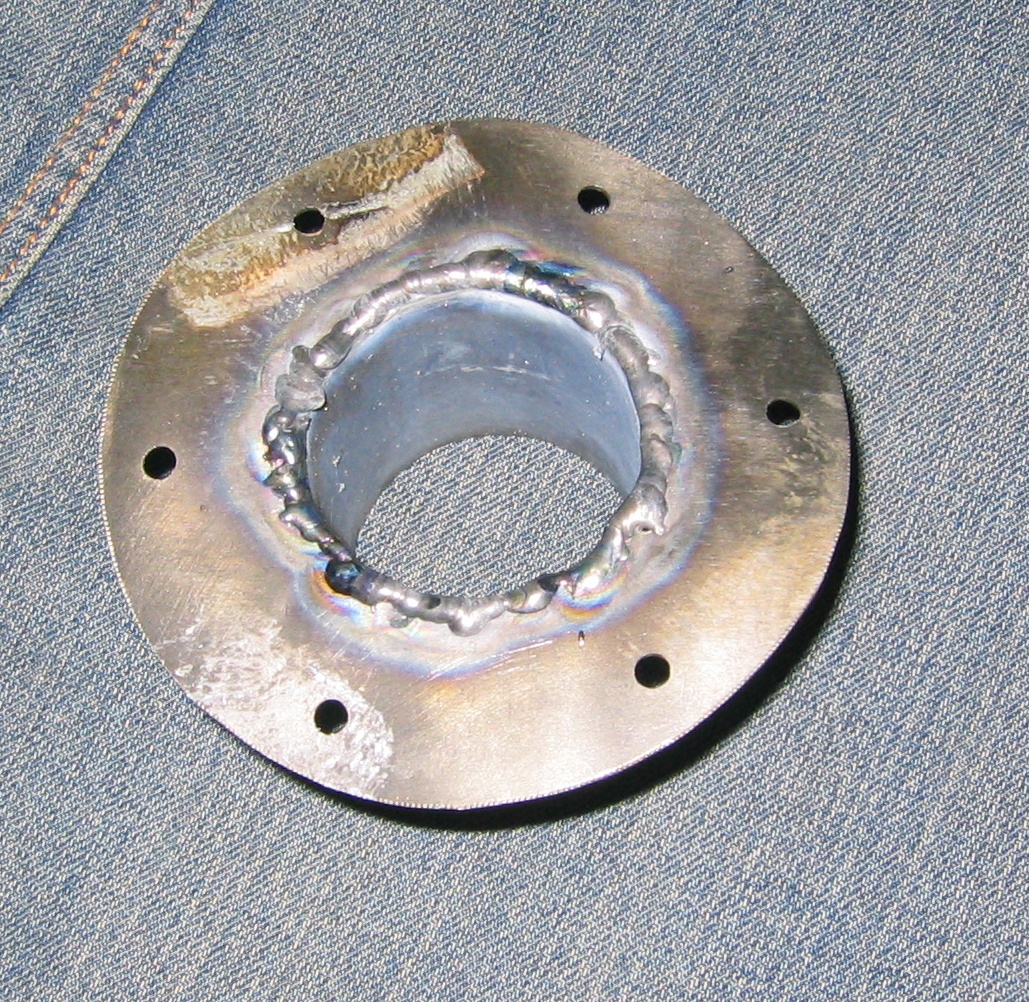

Here's me and the Rehmann's first attempt at welding titanium.

Pretty it aint. It would fail just about every test (see the discolouration) but, for the purpose it's intended for (flange between exhaust and carbon can) it'll do fine. Or, at least, it'll do fine after I've beaten the warping out of it (pretty much an inevitable consequence of using 1mm thick material for the flange -- an opened up section of tube -- but that's all I have!).

Trailing purge from a 2nd flowmeter, back purge from a disposable and a peanut tin with a hole poked in it in which the flange and tube sat. Filler rod was bits of scrap cut as fine as I could with shears (rod would have been better, but............).

I actually like welding this stuff: can't say I like working it, though. I'll look out for a see through blow up plastic thing to make a chamber from.

This here, not to show you what a wonderful welder I am (not ) but to say disregard the nay sayers and press on!

) but to say disregard the nay sayers and press on!

Pretty it aint. It would fail just about every test (see the discolouration) but, for the purpose it's intended for (flange between exhaust and carbon can) it'll do fine. Or, at least, it'll do fine after I've beaten the warping out of it (pretty much an inevitable consequence of using 1mm thick material for the flange -- an opened up section of tube -- but that's all I have!).

Trailing purge from a 2nd flowmeter, back purge from a disposable and a peanut tin with a hole poked in it in which the flange and tube sat. Filler rod was bits of scrap cut as fine as I could with shears (rod would have been better, but............).

I actually like welding this stuff: can't say I like working it, though. I'll look out for a see through blow up plastic thing to make a chamber from.

This here, not to show you what a wonderful welder I am (not

) but to say disregard the nay sayers and press on!

) but to say disregard the nay sayers and press on!

. He's either laughing all the way to the bank or (more likely) sitting by a very quiet phone

. He's either laughing all the way to the bank or (more likely) sitting by a very quiet phone