Hi there,

I own a SIP HandyMIG that I use for car bodywork. Having got fed up with the cost of the disposable gas cylinders (and the fact I weld outdoors) I have fitted a reel of 0.8 SIP gasless wire to my welder. It's working reasonably well but I know that to weld gasless properly, the torch should be negative and the clamp positive.

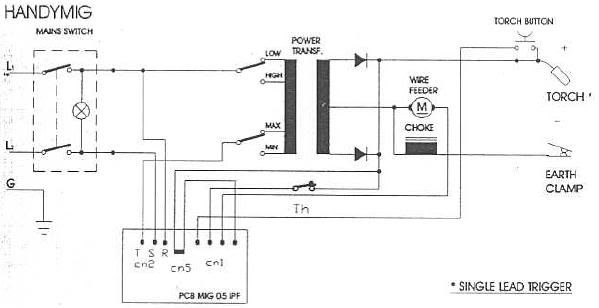

My SIP HandyMIG is the normal torch positive, clamp negative setup. I'd like to modify my welder to reverse the polarity. Looking at the schematic for the HandyMIG it looks to me like I could simply swap the torch and clamp - however - I'm worried about the trigger being shown on the schematic as being supplied by the single positive torch feed. This feeds back to the all important PCB :-

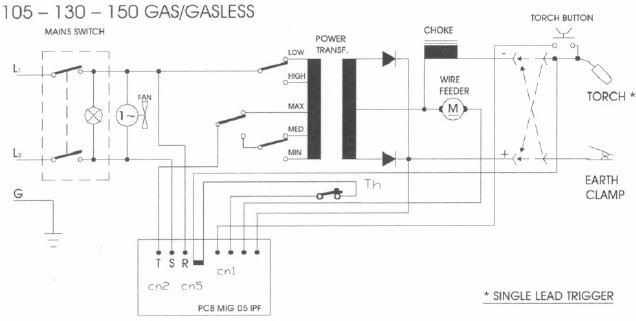

To get an idea of how I might convert my welder I thought I'd check a SIP schematic for a switchable polarity MIG welder. Surprisingly the schematic shows that the trigger can apparently be positive or negative! It also suggests that it's ok to feed either positive or negative back to the PCB which I find confusing?! :-

Does anyone see any reason (from looking at the 2 schematics) why it wouldn't be safe to simply swap the torch and the clamp over on my SIP HandyMIG so that I can weld gasless with the correct polarity?

Thanks in advance!

I own a SIP HandyMIG that I use for car bodywork. Having got fed up with the cost of the disposable gas cylinders (and the fact I weld outdoors) I have fitted a reel of 0.8 SIP gasless wire to my welder. It's working reasonably well but I know that to weld gasless properly, the torch should be negative and the clamp positive.

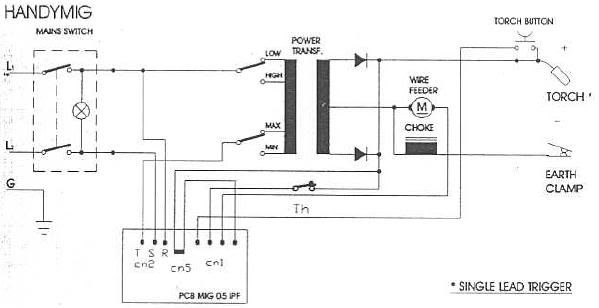

My SIP HandyMIG is the normal torch positive, clamp negative setup. I'd like to modify my welder to reverse the polarity. Looking at the schematic for the HandyMIG it looks to me like I could simply swap the torch and clamp - however - I'm worried about the trigger being shown on the schematic as being supplied by the single positive torch feed. This feeds back to the all important PCB :-

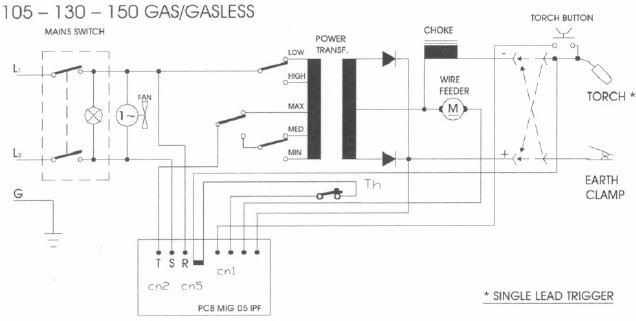

To get an idea of how I might convert my welder I thought I'd check a SIP schematic for a switchable polarity MIG welder. Surprisingly the schematic shows that the trigger can apparently be positive or negative! It also suggests that it's ok to feed either positive or negative back to the PCB which I find confusing?! :-

Does anyone see any reason (from looking at the 2 schematics) why it wouldn't be safe to simply swap the torch and the clamp over on my SIP HandyMIG so that I can weld gasless with the correct polarity?

Thanks in advance!