Paul.

Moderator

- Messages

- 7,052

- Location

- Northampton. UK

Another little job finished today, A roller track conveyor to feed an X ray cabinet.

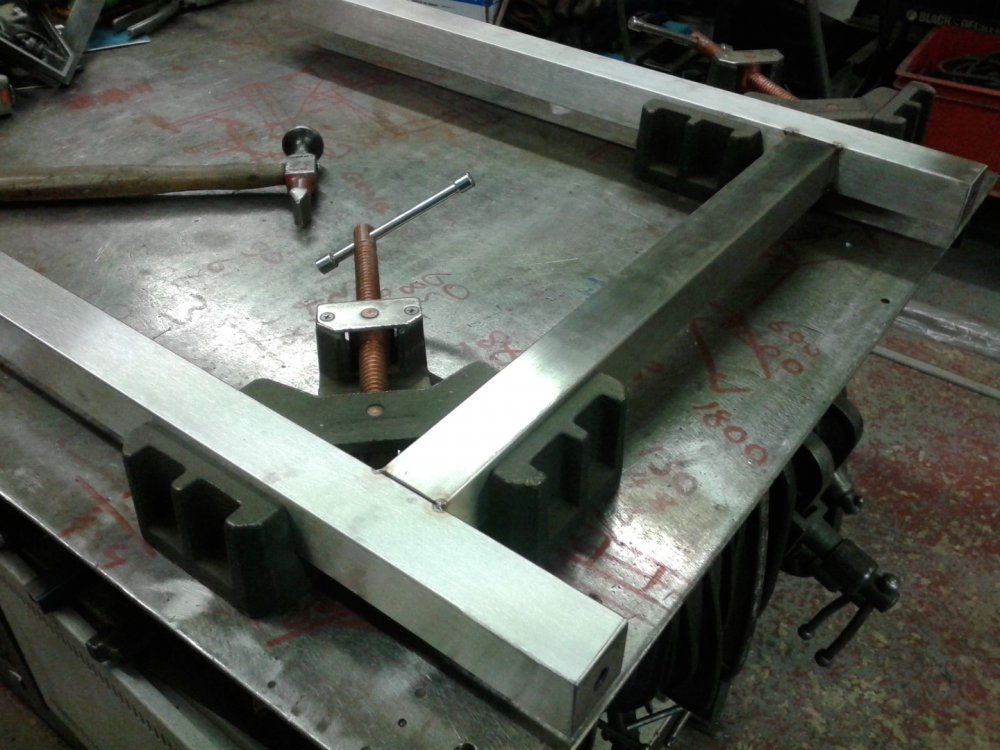

Frame is made from 40 x 40 stainless box section, fab one end up, using some mitre clamps here to keep it square.

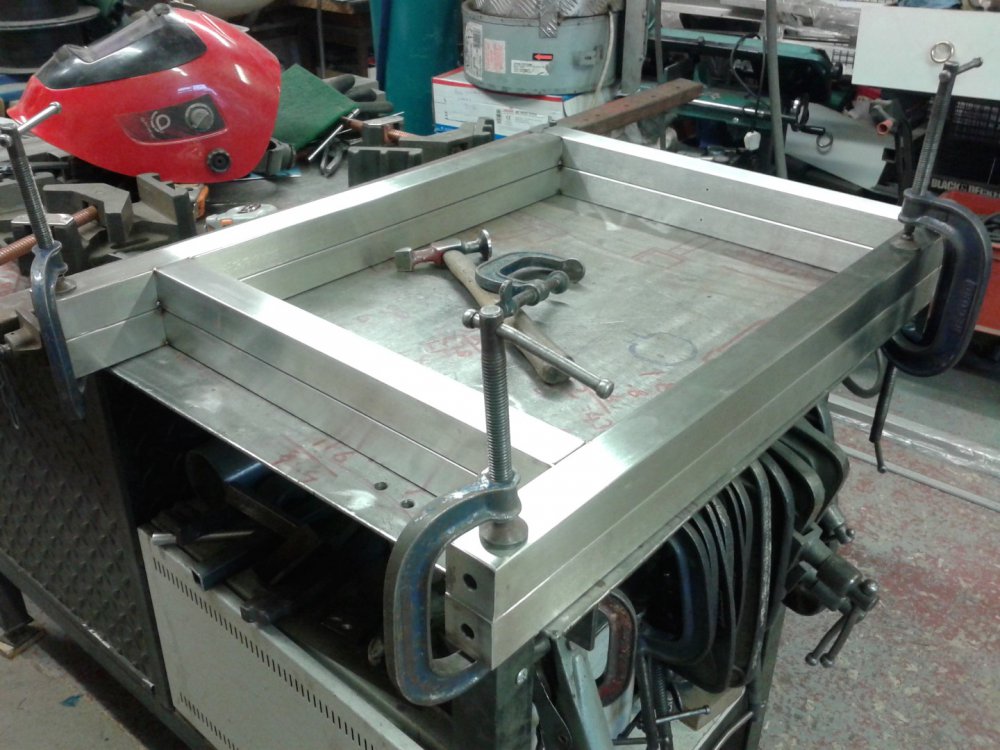

Then build the other end on top of it, the legs have been fitted with a 10mm thick pad at the bottom, drilled and tapped for adjustable feet.

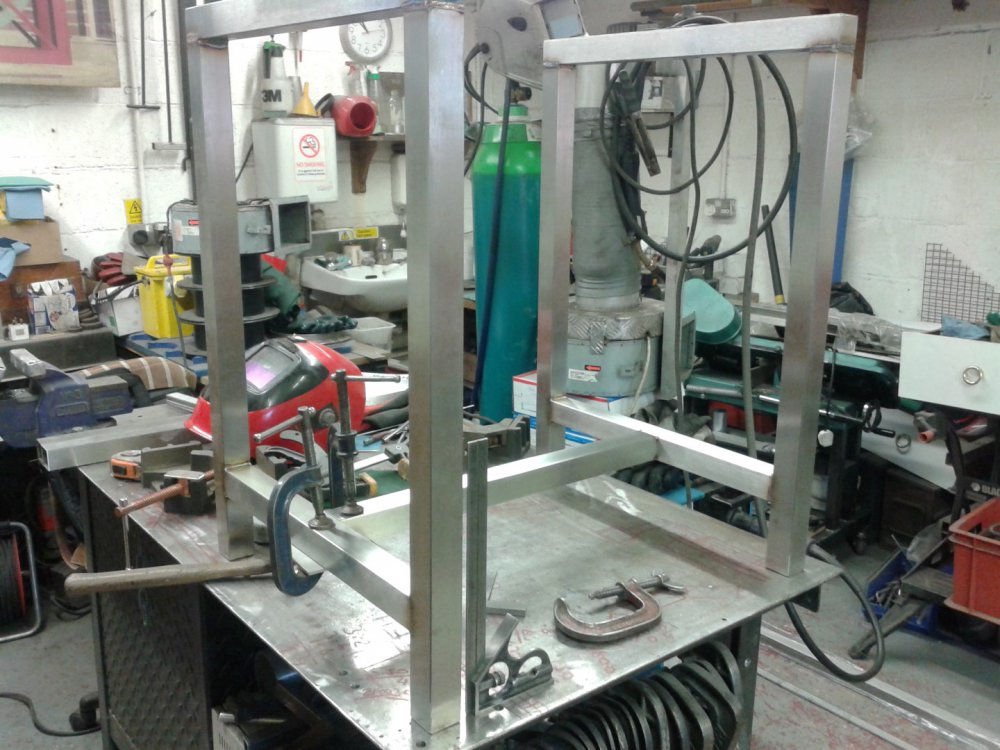

Putting it together.

The frame finished, and fitted with the adjustable feet.

It needs a tunnel to prevent the operators reaching imto the X ray cabinet, so a form a piece of 2mm sheet and some simple bent brackets,, stainless nutserts used to hold it to the frame, the joints have all just had a dose of pickling paste here

Some brackets with slots in every direction to tie it to existing studs on the cabinet

Fit the rollers and job done.

And offered up to the machine, just standing on a couple of trolleys here ready to be moved into the production area

Frame is made from 40 x 40 stainless box section, fab one end up, using some mitre clamps here to keep it square.

Then build the other end on top of it, the legs have been fitted with a 10mm thick pad at the bottom, drilled and tapped for adjustable feet.

Putting it together.

The frame finished, and fitted with the adjustable feet.

It needs a tunnel to prevent the operators reaching imto the X ray cabinet, so a form a piece of 2mm sheet and some simple bent brackets,, stainless nutserts used to hold it to the frame, the joints have all just had a dose of pickling paste here

Some brackets with slots in every direction to tie it to existing studs on the cabinet

Fit the rollers and job done.

And offered up to the machine, just standing on a couple of trolleys here ready to be moved into the production area