Hi Guys

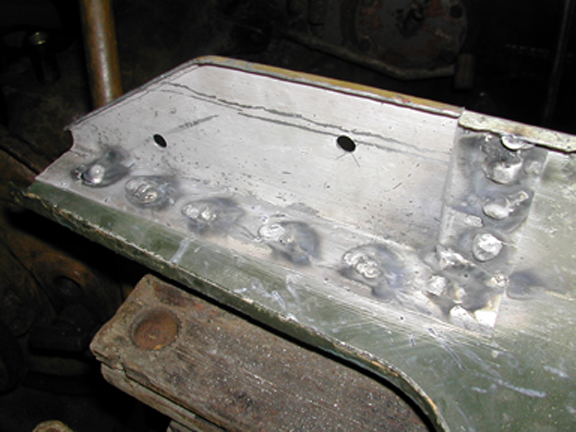

A few months ago I was asking about welding birmabright ally on my land rover. About ready to start to sort the panels out this weekend.

What is the best corrosion / paint removal method. Grinder? stone discs? wire brush etc , without damaging the metal.

I have a small grit blaster which seems to get rid of the white stuff well.

I was thinking of cleaning out behind and patching with same type of ally and glueing (jb weld / silicone? ). Then a smear of filler over the outside? Poss a few pop rivets to hold it?

Basically afraid to weld it unless you guys can inspire me.

(have mig / and mapp gas plumbers torch and pop riverter)

If I can get to a gas set to experiment, is the 'filler' proper ally magnesium rod or can you use strips of original metal?

Any thoughts on stopping the corrosion between steel and ally. Rubber strip?

How about using stainless nuts and bolts? Better than steel?

Where there are stress fractures?? What next?

Thanks and happy christmas all.

A few months ago I was asking about welding birmabright ally on my land rover. About ready to start to sort the panels out this weekend.

What is the best corrosion / paint removal method. Grinder? stone discs? wire brush etc , without damaging the metal.

I have a small grit blaster which seems to get rid of the white stuff well.

I was thinking of cleaning out behind and patching with same type of ally and glueing (jb weld / silicone? ). Then a smear of filler over the outside? Poss a few pop rivets to hold it?

Basically afraid to weld it unless you guys can inspire me.

(have mig / and mapp gas plumbers torch and pop riverter)

If I can get to a gas set to experiment, is the 'filler' proper ally magnesium rod or can you use strips of original metal?

Any thoughts on stopping the corrosion between steel and ally. Rubber strip?

How about using stainless nuts and bolts? Better than steel?

Where there are stress fractures?? What next?

Thanks and happy christmas all.