TIG Welding Tutorial

This tutorial is intended to offer practical advice to complete beginner TIG welders but should also be useful to intermediate welders.

There's no single 'learn to TIG' page, instead each page demonstrates aspects of the technique using different joint types. As usual the tutorial is not a substitute for a college course or time with a professional, but it should cover the basics. Feel free to ask on the forum if you get stuck.

Set Up

Just enough information to get the machine set up for the tutorials.

The page details how to grind the tungsten, how far the tungsten should stick out from the shroud, gas flow and machine settings.

TIG Amp Chart

Learning to TIG weld is tricky enough without having to guess the amps. We've written down the amps, tungsten size and filler rod diameter that we would choose for different joints, materials and thicknesses. You can print them out and stick them to your welder.

There is no definitive chart for this sort of thing - the choice of amps depends a lot on technique and travel speed, but it's handy to have a starting point.

TIG Welding Technique

TIG is a very precise process, much more so than MIG or Arc, so if you are moving from those processes pay attention to the tips on how to set up your body position to achieve the necessary precision.

We've produced a few videos to illustrate how to TIG weld. The page covers the technique itself and what to aim for.

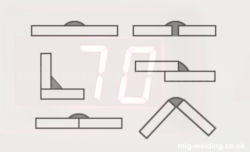

Butt Weld and Tacking

Don't spend too much time laying TIG beads - when you get the hang of moving the weld pool along it's much more fun and informative to try a joint.

We've also covered tacking in this section.

Fillet Welds

Fillet welds are an excellent test of technique. Once you have clicked with fillets all of your other TIG welding should be good.

The earlier pages talk about things like the arc gap and how the filler rod affects the weld. Fillets will force good technique in these areas.

Lap Joints

We've covered the main techniques so for completeness it's worth offering some advice on the other types of joint you might want to do. Lap joints are very much like fillet joints, just you are welding end-on rather than side-on to the sheet on top.

The lap joint page covers the trouble that involves.

Outside Corner Weld

Outside corner joints introduce gas issues as well as positioning issues. That makes them a great way to finish off the technique section of the tutorial.

An inside corner (fillet) will demand more amps and will cope with a smaller shroud than butt welds. An outside corner is the opposite - the gas is not contained by the joint, and there is nowhere for the heat to go so amps need to be reduced.

Credits

Many thanks to Paul Holland who spent several days helping prepare the material for this tutorial and taught me to TIG weld at the same time.

Thanks also to Weldequip for the loan of an Inverter Fusion 200HF when I was struggling with my Syncrowave. The IFL transformed my TIG welding.

Finally a big thanks to all the forum supporters who funded the tutorial. If you found the tutorial useful don't hesitate to donate and help fund more useful stuff. Otherwise you can contribute by helping others on the forum.