Submariner1

Member

- Messages

- 194

- Location

- Berkshire

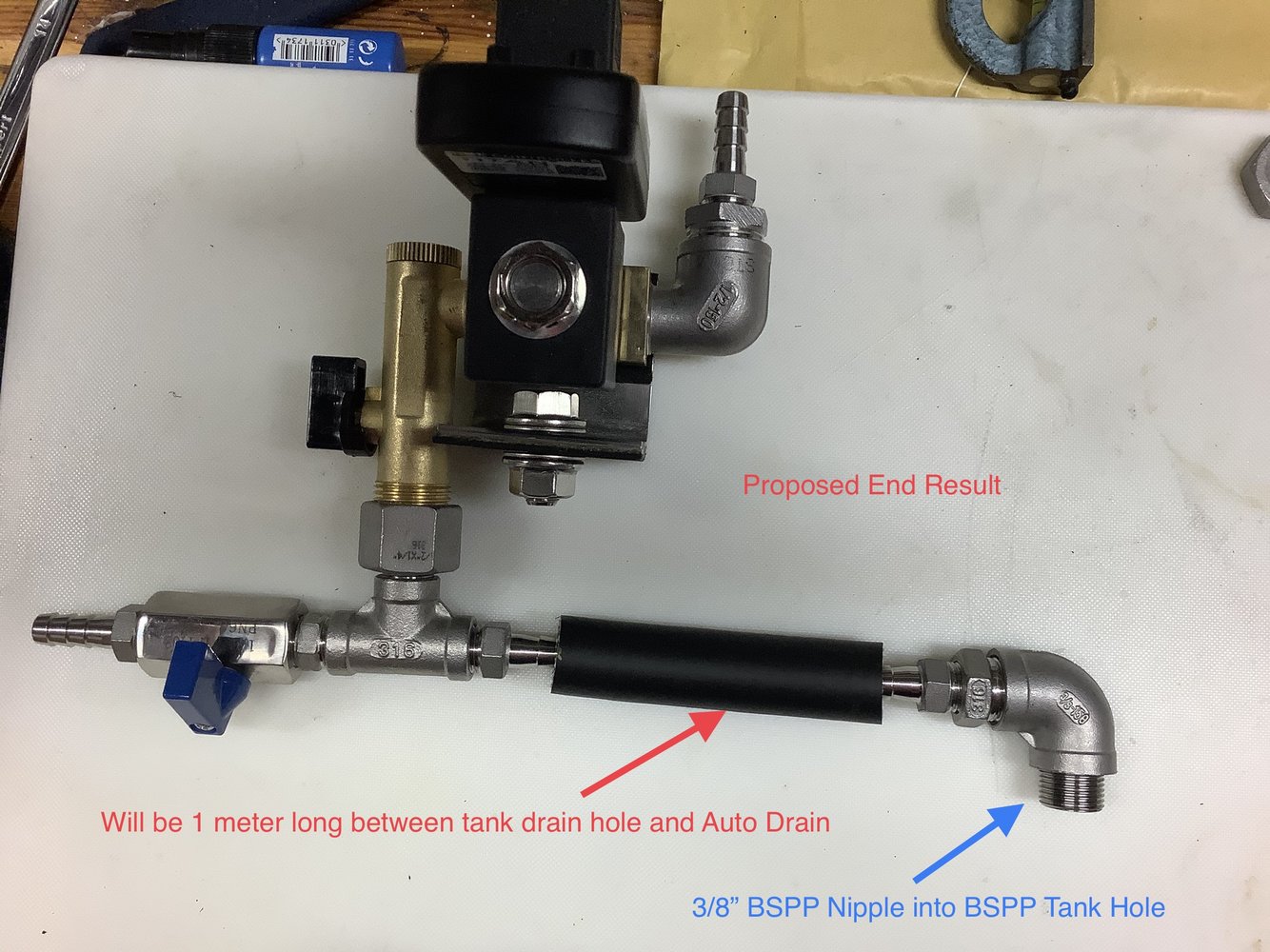

Just got some stainless fittings, but a slight problem. I had hoped the bspp elbow and parallel nipple would be sufficiently tight to cement with Loctitie 577 sealant (that I have) without a leak.

But this joint or mating is really very sloppy. Note I did have my only slight leak using 577, when using BPPT INTO BSPP when they were not tight ( i.e. to get the direction of the fitting correct).

I want to avoid this, because its very fiddly working under the tank with confined access!

I selected a BSPP Nipple rather than a street elbow, to avoid the above leak scenario, and also be able to set the angle of direction exactly as I wanted it.

Note I have not yet removed the std. Drain cock - so no idea if this nipple will lock up into a “shoulder” or will go straight through the tank - hence without this knowledge I need to be able to select the right amount of turns, so the direction is correct, and also avoid the male end going too high in the tank, causing a water trap.

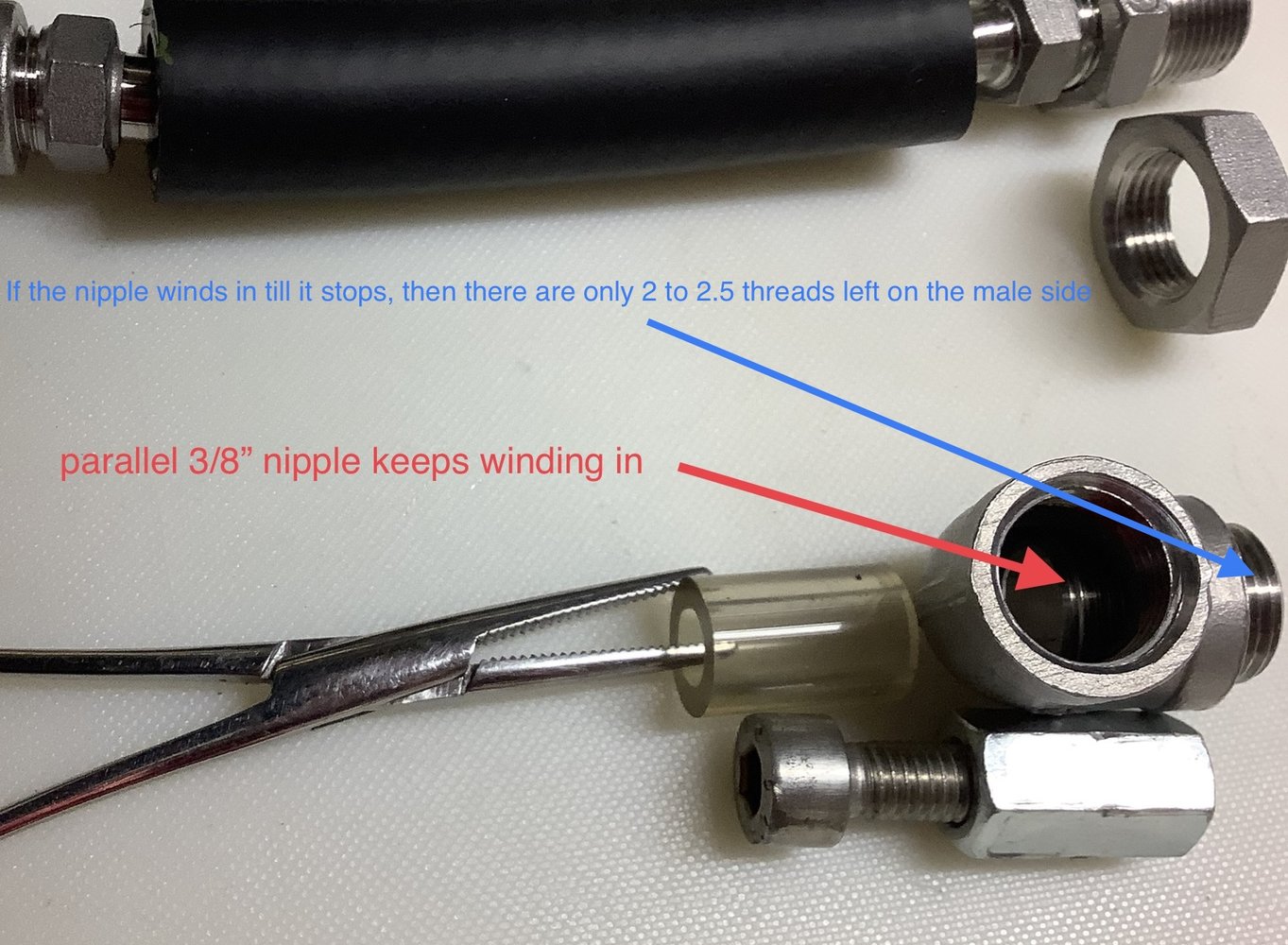

Hence my problem of a sloppy connection - i.e. want to avoid winding in this joint blind, and not sharing the Nipple equally.

Q1. Should BSPP to BSPP fittings be reasonably close, i.e. not wobbly? If so a replacement would solve my issue.

or if its normal to have sloppy fittings ?

Then

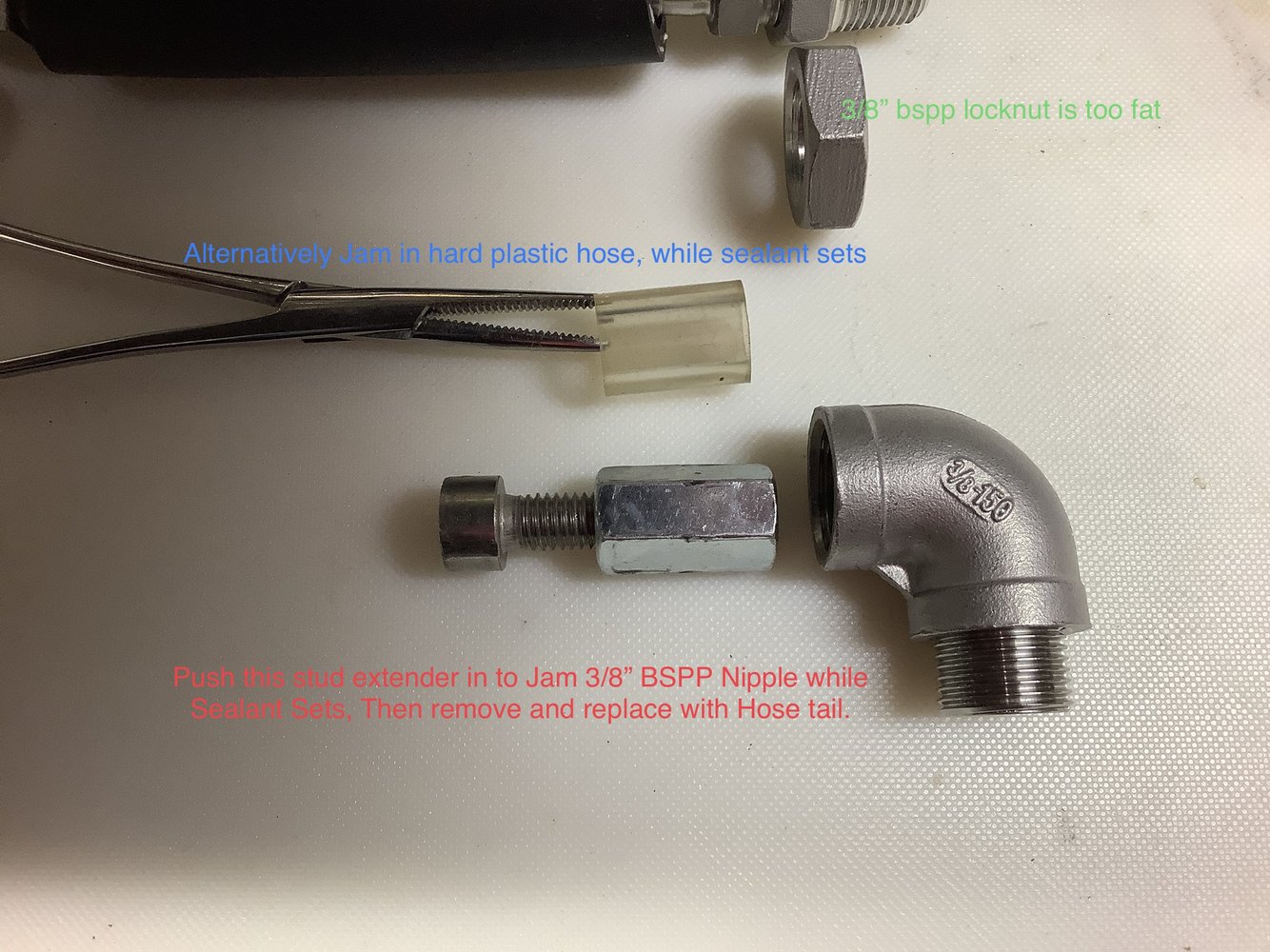

Q2. would jamming the nipple whilst the sealant sets work? Albeit only done up hand tight.

or

Q3. Will the sealant overcome this looseness and not leak because it is BSPP to BSPP.?

Ideas to jam the nipple

Apologies for the long winded explanation, but the devil is in the detail.

if I knew whether the tank drain hole had a shoulder to stop the nipple; then I could just go ahead and lock the nipple into that, and then wind this elbow on until it stopped (pointing In the right direction), and if needed, shim it with washers.

But if both ends are free spinning I wont know if the nipple was winding up into the tank creating a water trap, and the elbow hanging on by 2 threads!

plus once I undo the tanks original drain - then the compressor is unusable till I solve this.

But this joint or mating is really very sloppy. Note I did have my only slight leak using 577, when using BPPT INTO BSPP when they were not tight ( i.e. to get the direction of the fitting correct).

I want to avoid this, because its very fiddly working under the tank with confined access!

I selected a BSPP Nipple rather than a street elbow, to avoid the above leak scenario, and also be able to set the angle of direction exactly as I wanted it.

Note I have not yet removed the std. Drain cock - so no idea if this nipple will lock up into a “shoulder” or will go straight through the tank - hence without this knowledge I need to be able to select the right amount of turns, so the direction is correct, and also avoid the male end going too high in the tank, causing a water trap.

Hence my problem of a sloppy connection - i.e. want to avoid winding in this joint blind, and not sharing the Nipple equally.

Q1. Should BSPP to BSPP fittings be reasonably close, i.e. not wobbly? If so a replacement would solve my issue.

or if its normal to have sloppy fittings ?

Then

Q2. would jamming the nipple whilst the sealant sets work? Albeit only done up hand tight.

or

Q3. Will the sealant overcome this looseness and not leak because it is BSPP to BSPP.?

Ideas to jam the nipple

Apologies for the long winded explanation, but the devil is in the detail.

if I knew whether the tank drain hole had a shoulder to stop the nipple; then I could just go ahead and lock the nipple into that, and then wind this elbow on until it stopped (pointing In the right direction), and if needed, shim it with washers.

But if both ends are free spinning I wont know if the nipple was winding up into the tank creating a water trap, and the elbow hanging on by 2 threads!

plus once I undo the tanks original drain - then the compressor is unusable till I solve this.