Submariner1

Member

- Messages

- 194

- Location

- Berkshire

I would like to either:-

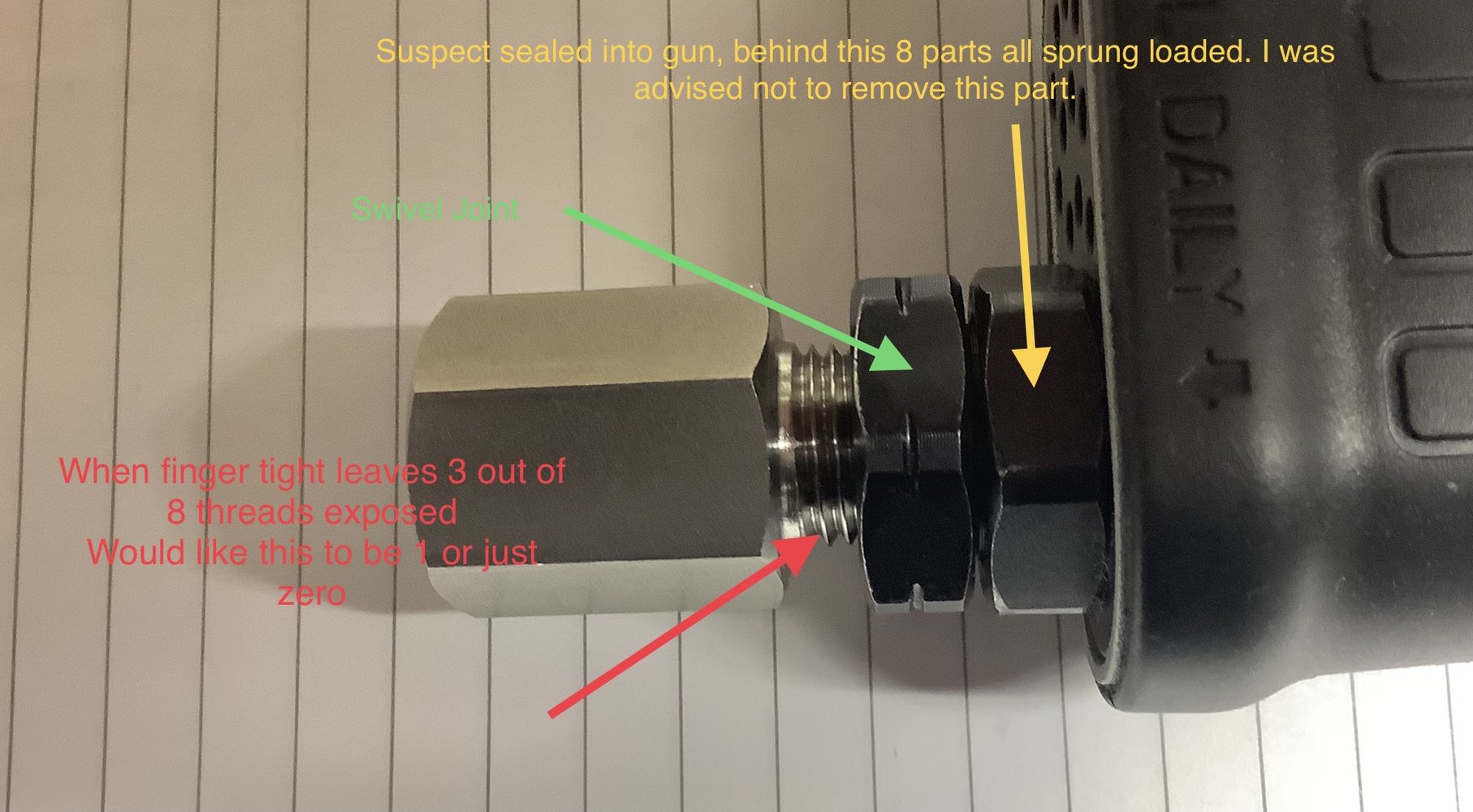

1. Make the existing 1/4” female tapered thread deeper, so the tapered male goes in further i.e. preferably almost flush. (see photo1)

or

2. Ideally I would like to convert the rather shoddily cut 1/4” BSP T (Tapered) Female into a 1/4” BSPP (Parallel) Female.

But I do not want to risk it, as there are no more spares for this expensive gun, that I bought for peanuts.

Main reason:

1. Its not deep enough ... only screws in 4 threads out of 8. See first photo

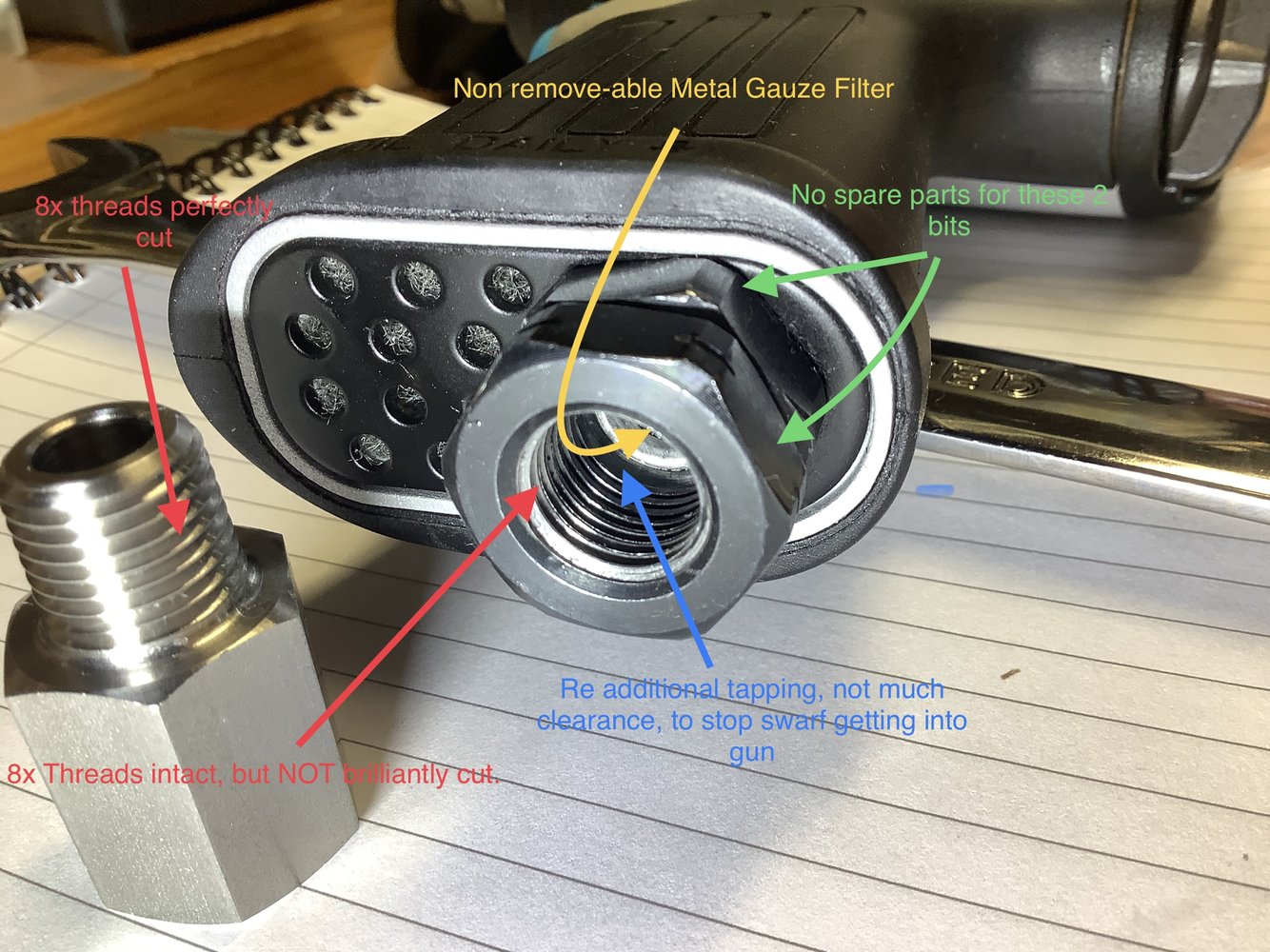

2. As the female thread was badly cut, its a bit rough. See 2nd Photo.

Unfortunately this acts like a cheese grater on the ptfe tape. On the face of it no biggie, as it seals. But it means a procrastinated clean out with a needle after each use, just to inject some oil. I far prefer parallel threads with an O ring for stuff one regularly removes.

By doing either, hopefully the thread quality will also be improved.

Caveat: Although new there are no spares for this gun! Apparently its tricky to reassemble, if you take out the whole swivel joint, as there are 8 small parts all sprung loaded behind this, plus I am sure it would require heating to undo the sealant ... so not an option - any thread cutting has to be done in situ.

I plan to put some blutack on the gauze when tapping, and frequently clean out; and then clean out and remove blutack.

Note: My only experience of tapping threads is limited to cutting or cleaning up parallel threads and I have 4mm to 10mm metric course sets of 3 cutters (Taper - First cut, Second cut & Plug).

I suspect as the Tapered thread is already technically cut; it might be easier to just buy a Plug Tap ( i.e. 3rd Cut Tap for a “1/4” BSP ‘T’ Tapered Thread” and work this down to the last thread already cut.

Q. Can I get away with buying just the final Plug or as some call it the Bottom Cut Tap (for a tapered thread) ?

Q. Or does it not work like that? i.e. would I need to buy a Second Cut and a Plug Tap? (even though you are just “widening” the last threads).

Q. Or does it in fact depend on the angle of the thread, i.e. could I end up just cleaning up the thread, but the male wont go in further. Namely to achieve this I may need to extend the amount of threads in the female? ( which I can’t do in situ ref the filter).

Note: Dont mind investing in a set of 3 for Parallel BSP, but would rather buy the minimum tapered ones, as I hate using them.

Alternatively

Q. Can one “easily” with no more risk tap out and ‘convert’ an existing tapered 1/4” female, into a 1/4” Parallel female? i.e. Would the existing threaded hole be wide enough to easily accept the Parallel Tap cutters. Or is that problematic for any reason?

Q. If its feasible, would I need a Parallel ‘Second Cut’ and ‘Plug cut’ Taps to do this ( cut down to the 8th thread) ? Or all three of the set?

Getting conflicting info from Google re the metric diameter of the drill needed for 1/4” BSP

BSPP Parallel says 11.8mm or 11.5mm?

BSPT Tapered 10.8mm, or 11.2mm?

Q. Which are right?

Anyway my logic was:- if the existing tapered hole is already tapped out to 11.7mm (purely by measuring the well cut fitting) then I wont need pilot drilling?. Or does it mean the hole is too big and therefore the parallel Tap won’t grip or will tear-out before cutting? In the case of converting to parallel will the existing bore be too little, or did the initial tapered cut, make the hole big enough?

Hence be good to know if is it easier to do either a) Deepen a tapered female or b) convert to Parallel.

Note the end clearance before the non remove-able gauze filter.

Not too fussed which method, because if Tapered is the safest and easiest way to go. Then I will choose that. And then just use Loctite 577 into the gun swivel and add another parallel one onto the whip hose.

Any advice much appreciated, as I don’t wan’t to risk an unusable gun, neither waste money on Taps that won’t solve the issue.

The 1/4” BSPT Tapered joint I wan’t to extend or convert

1. Make the existing 1/4” female tapered thread deeper, so the tapered male goes in further i.e. preferably almost flush. (see photo1)

or

2. Ideally I would like to convert the rather shoddily cut 1/4” BSP T (Tapered) Female into a 1/4” BSPP (Parallel) Female.

But I do not want to risk it, as there are no more spares for this expensive gun, that I bought for peanuts.

Main reason:

1. Its not deep enough ... only screws in 4 threads out of 8. See first photo

2. As the female thread was badly cut, its a bit rough. See 2nd Photo.

Unfortunately this acts like a cheese grater on the ptfe tape. On the face of it no biggie, as it seals. But it means a procrastinated clean out with a needle after each use, just to inject some oil. I far prefer parallel threads with an O ring for stuff one regularly removes.

By doing either, hopefully the thread quality will also be improved.

Caveat: Although new there are no spares for this gun! Apparently its tricky to reassemble, if you take out the whole swivel joint, as there are 8 small parts all sprung loaded behind this, plus I am sure it would require heating to undo the sealant ... so not an option - any thread cutting has to be done in situ.

I plan to put some blutack on the gauze when tapping, and frequently clean out; and then clean out and remove blutack.

Note: My only experience of tapping threads is limited to cutting or cleaning up parallel threads and I have 4mm to 10mm metric course sets of 3 cutters (Taper - First cut, Second cut & Plug).

I suspect as the Tapered thread is already technically cut; it might be easier to just buy a Plug Tap ( i.e. 3rd Cut Tap for a “1/4” BSP ‘T’ Tapered Thread” and work this down to the last thread already cut.

Q. Can I get away with buying just the final Plug or as some call it the Bottom Cut Tap (for a tapered thread) ?

Q. Or does it not work like that? i.e. would I need to buy a Second Cut and a Plug Tap? (even though you are just “widening” the last threads).

Q. Or does it in fact depend on the angle of the thread, i.e. could I end up just cleaning up the thread, but the male wont go in further. Namely to achieve this I may need to extend the amount of threads in the female? ( which I can’t do in situ ref the filter).

Note: Dont mind investing in a set of 3 for Parallel BSP, but would rather buy the minimum tapered ones, as I hate using them.

Alternatively

Q. Can one “easily” with no more risk tap out and ‘convert’ an existing tapered 1/4” female, into a 1/4” Parallel female? i.e. Would the existing threaded hole be wide enough to easily accept the Parallel Tap cutters. Or is that problematic for any reason?

Q. If its feasible, would I need a Parallel ‘Second Cut’ and ‘Plug cut’ Taps to do this ( cut down to the 8th thread) ? Or all three of the set?

Getting conflicting info from Google re the metric diameter of the drill needed for 1/4” BSP

BSPP Parallel says 11.8mm or 11.5mm?

BSPT Tapered 10.8mm, or 11.2mm?

Q. Which are right?

Anyway my logic was:- if the existing tapered hole is already tapped out to 11.7mm (purely by measuring the well cut fitting) then I wont need pilot drilling?. Or does it mean the hole is too big and therefore the parallel Tap won’t grip or will tear-out before cutting? In the case of converting to parallel will the existing bore be too little, or did the initial tapered cut, make the hole big enough?

Hence be good to know if is it easier to do either a) Deepen a tapered female or b) convert to Parallel.

Note the end clearance before the non remove-able gauze filter.

Not too fussed which method, because if Tapered is the safest and easiest way to go. Then I will choose that. And then just use Loctite 577 into the gun swivel and add another parallel one onto the whip hose.

Any advice much appreciated, as I don’t wan’t to risk an unusable gun, neither waste money on Taps that won’t solve the issue.

The 1/4” BSPT Tapered joint I wan’t to extend or convert