bigbadbugga

Member

- Messages

- 1,004

Hope I have got this in the right section, please move it if not

I need some opinions please.

I am at the point on my subaru/vw project where I need to be welding bracing and new brackets to the chassis. Most of the steel I will be using is 3mm thick, comprising of RHS and flat bar.

My welder is a clarke 105 turbo (the blue one), I've bought a new reel of 0.8mm wire and tips and had a go at laying some beads on an offcut.

Most of the beads seem to lay on top with a high profile, but after a bit of fiddling with settings I managed two beads that look ok.

set on 2-max, wire feed at 5, gas is CO2 (no flow guage but good flow)

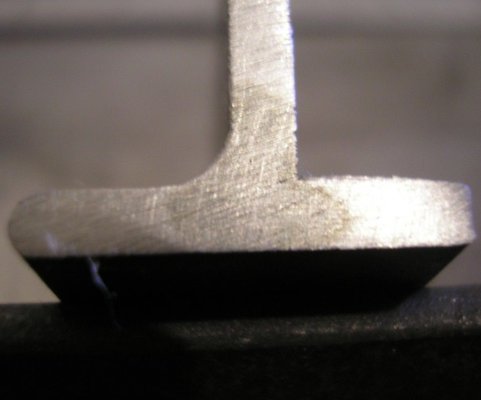

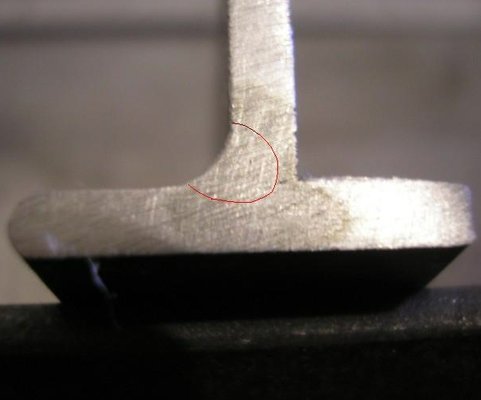

I sectioned the welds on my bandsaw and cleaned up the saw marks...

I suspect my welder is a bit short on power for the job, am I right?

If so, would I be ok tacking everything together using it until I get a more powerful machine?

Is there anything I can do to improve the penetration?

thanks in advance

I need some opinions please.

I am at the point on my subaru/vw project where I need to be welding bracing and new brackets to the chassis. Most of the steel I will be using is 3mm thick, comprising of RHS and flat bar.

My welder is a clarke 105 turbo (the blue one), I've bought a new reel of 0.8mm wire and tips and had a go at laying some beads on an offcut.

Most of the beads seem to lay on top with a high profile, but after a bit of fiddling with settings I managed two beads that look ok.

set on 2-max, wire feed at 5, gas is CO2 (no flow guage but good flow)

I sectioned the welds on my bandsaw and cleaned up the saw marks...

I suspect my welder is a bit short on power for the job, am I right?

If so, would I be ok tacking everything together using it until I get a more powerful machine?

Is there anything I can do to improve the penetration?

thanks in advance