Sphinx

Member

- Messages

- 198

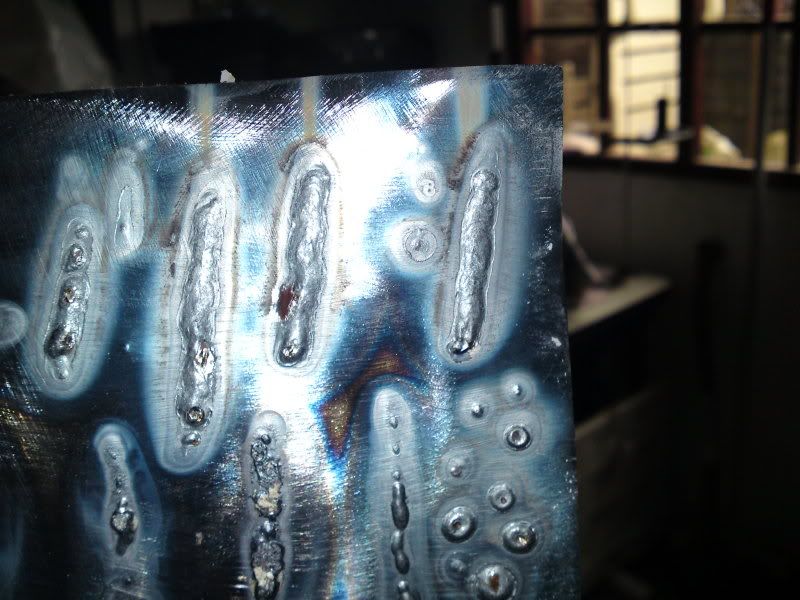

Once I'd prepared some steel to practice on and set everything up, I fired up the welder and gave it a go.

However...after I'd ruled out my novice skills being the cause for some terrible welds I realised there was no gas getting through, so after a bit of a fiddle (pipe had popped off inside the machine) it was time for take 2.

Here are the pics:

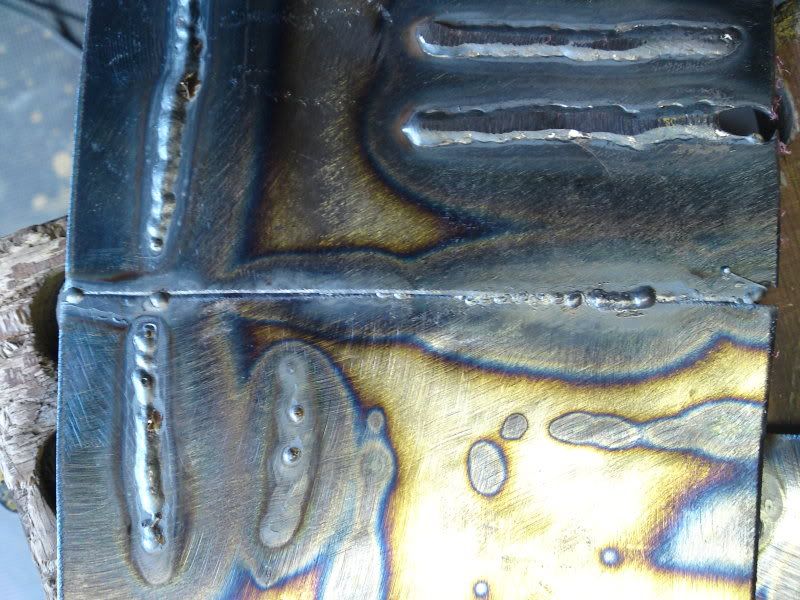

Reverse side:

At this point I was just playing around with various settings and found that I could get a decent enough (in my humble opinion) on either of the lowest settings with a variety of wire speeds by just adjusting my speed. I still find the lowest setting and going fairly slowly produces my neatest work.

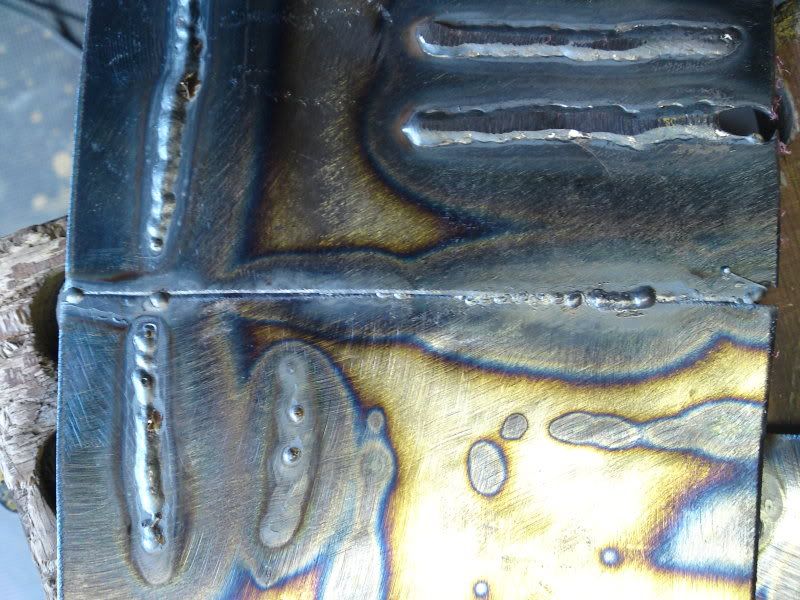

Then I tried some butt welding and overlap welding. I find them both tricky at the moment but overlap joins are the hardest for me.

One of the biggest things I noticed was; it's all well and good getting some neat welds laid onto a single sheet of steel but things get much harder when you actually try and join things together lol

However...after I'd ruled out my novice skills being the cause for some terrible welds I realised there was no gas getting through, so after a bit of a fiddle (pipe had popped off inside the machine) it was time for take 2.

Here are the pics:

Reverse side:

At this point I was just playing around with various settings and found that I could get a decent enough (in my humble opinion) on either of the lowest settings with a variety of wire speeds by just adjusting my speed. I still find the lowest setting and going fairly slowly produces my neatest work.

Then I tried some butt welding and overlap welding. I find them both tricky at the moment but overlap joins are the hardest for me.

One of the biggest things I noticed was; it's all well and good getting some neat welds laid onto a single sheet of steel but things get much harder when you actually try and join things together lol

Last edited: