jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

Ive had the afternoon off today so here it is.

First thing I sourced was a beer barrel the one I got was a stainless steel one I don’t know if it makes any different whether you have an ally one or not but heat wise glad I had stainless. Plus it made the build better for welding.

I cut off the top and turn the top over this became the lid.

I cut a hole in the base of the barrel this was to become the drain should I have any molten metal spills.

I also at this time cut the hole in the side for the burner, I new I was using a 65mm tube burner so the hole was cut to suit here you will need to cut what ever size burner tube you’re going to use.

Regarding the height of hole and angle I was aiming for 100mm thickness off the bottom and aiming to have 100mm thick sides so you will need to allow for this when cutting the burner hole. Depending how thick your having your furnace walls, ie the thicker it is the more heat your furnace will hold and how quickly it gets up to temp and how fast it cools. On the down side the thicker your mortar and insulation is, the smaller the melting pot or crucible you will be able to use, these factors will need thinking about before you build.

I then added some steel bar reinforcing bars in the lid I had some off cuts of stainless about so that was used I suppose you could also use standard reinforcing bar or just plain round steel bar.

Inside the barrel still using the off cuts added some reinforcing bars to the bottom and some smaller bars up the side to give the mortar something to bind to I don’t really know if this is really necessary but I am an over builder lol

At this point I started to make up some sort of trolley as I figured it was going to rather heavy with all the cement and luckily I decided that I wanted a way of moving the lid about rather than lifting it on and off. I made a foot pedal so when you push it down it lifts the lid only about an inch or so, the lid can then be swung left or right.

This is what I did but you can build your trolley anyway you like. Oh one thing make sure you get some good strong castors if following my route. This way does work well though, and believe me you do not want to be thinking you’re going to be lifting the lid on and off, the heat and weight is immense.

First thing I sourced was a beer barrel the one I got was a stainless steel one I don’t know if it makes any different whether you have an ally one or not but heat wise glad I had stainless. Plus it made the build better for welding.

I cut off the top and turn the top over this became the lid.

I cut a hole in the base of the barrel this was to become the drain should I have any molten metal spills.

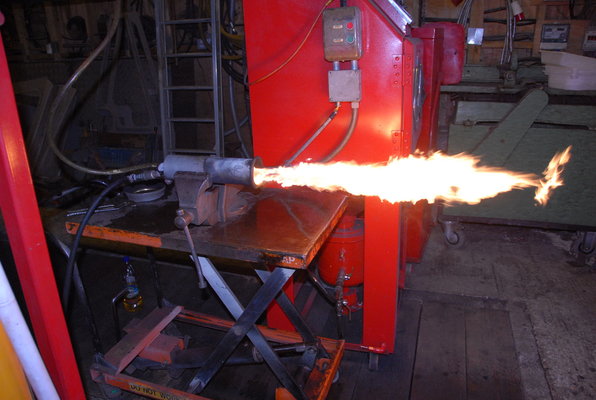

I also at this time cut the hole in the side for the burner, I new I was using a 65mm tube burner so the hole was cut to suit here you will need to cut what ever size burner tube you’re going to use.

Regarding the height of hole and angle I was aiming for 100mm thickness off the bottom and aiming to have 100mm thick sides so you will need to allow for this when cutting the burner hole. Depending how thick your having your furnace walls, ie the thicker it is the more heat your furnace will hold and how quickly it gets up to temp and how fast it cools. On the down side the thicker your mortar and insulation is, the smaller the melting pot or crucible you will be able to use, these factors will need thinking about before you build.

I then added some steel bar reinforcing bars in the lid I had some off cuts of stainless about so that was used I suppose you could also use standard reinforcing bar or just plain round steel bar.

Inside the barrel still using the off cuts added some reinforcing bars to the bottom and some smaller bars up the side to give the mortar something to bind to I don’t really know if this is really necessary but I am an over builder lol

At this point I started to make up some sort of trolley as I figured it was going to rather heavy with all the cement and luckily I decided that I wanted a way of moving the lid about rather than lifting it on and off. I made a foot pedal so when you push it down it lifts the lid only about an inch or so, the lid can then be swung left or right.

This is what I did but you can build your trolley anyway you like. Oh one thing make sure you get some good strong castors if following my route. This way does work well though, and believe me you do not want to be thinking you’re going to be lifting the lid on and off, the heat and weight is immense.