brewdexta

The biggest tool in the box

- Messages

- 5,756

- Location

- UK

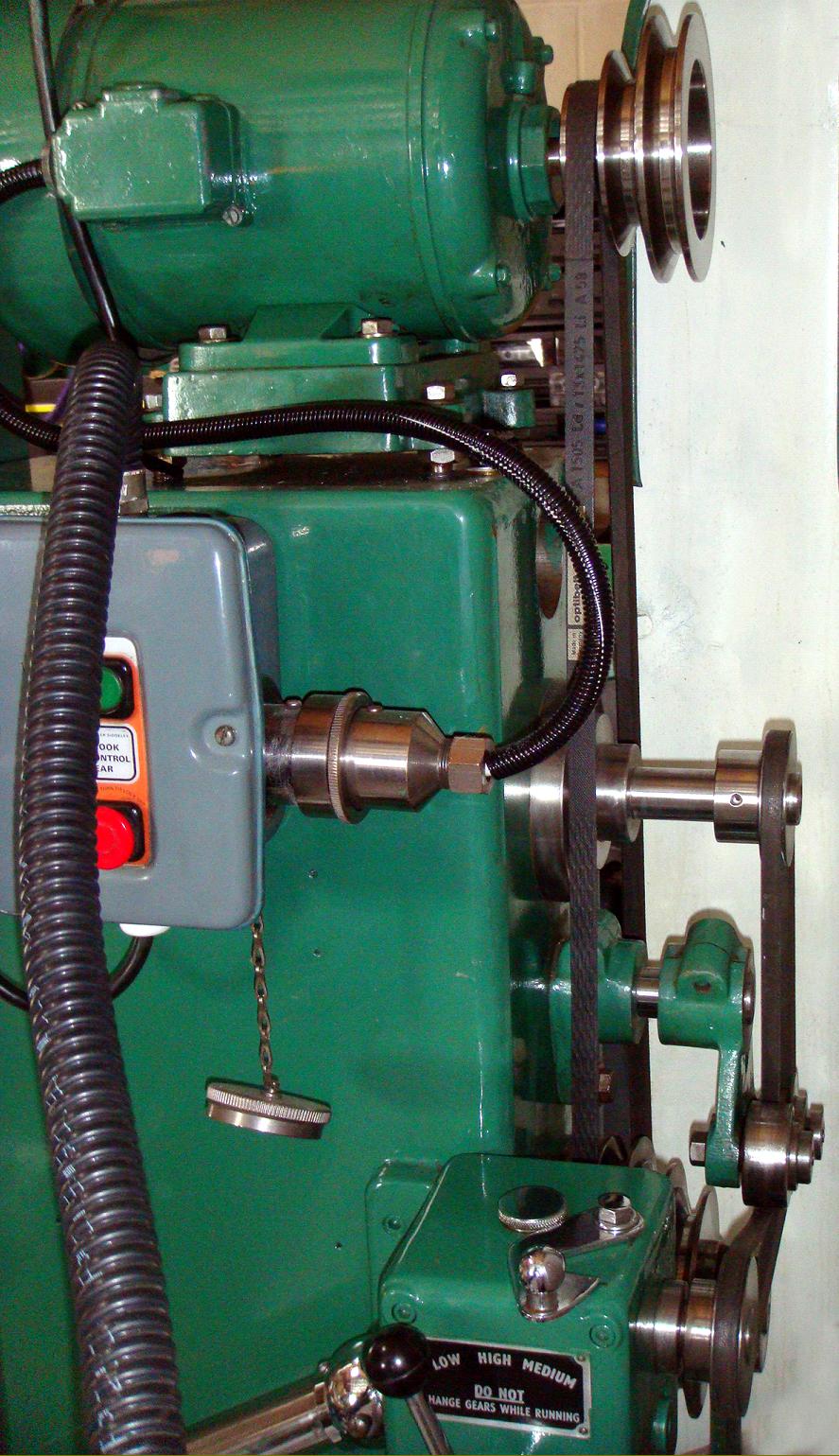

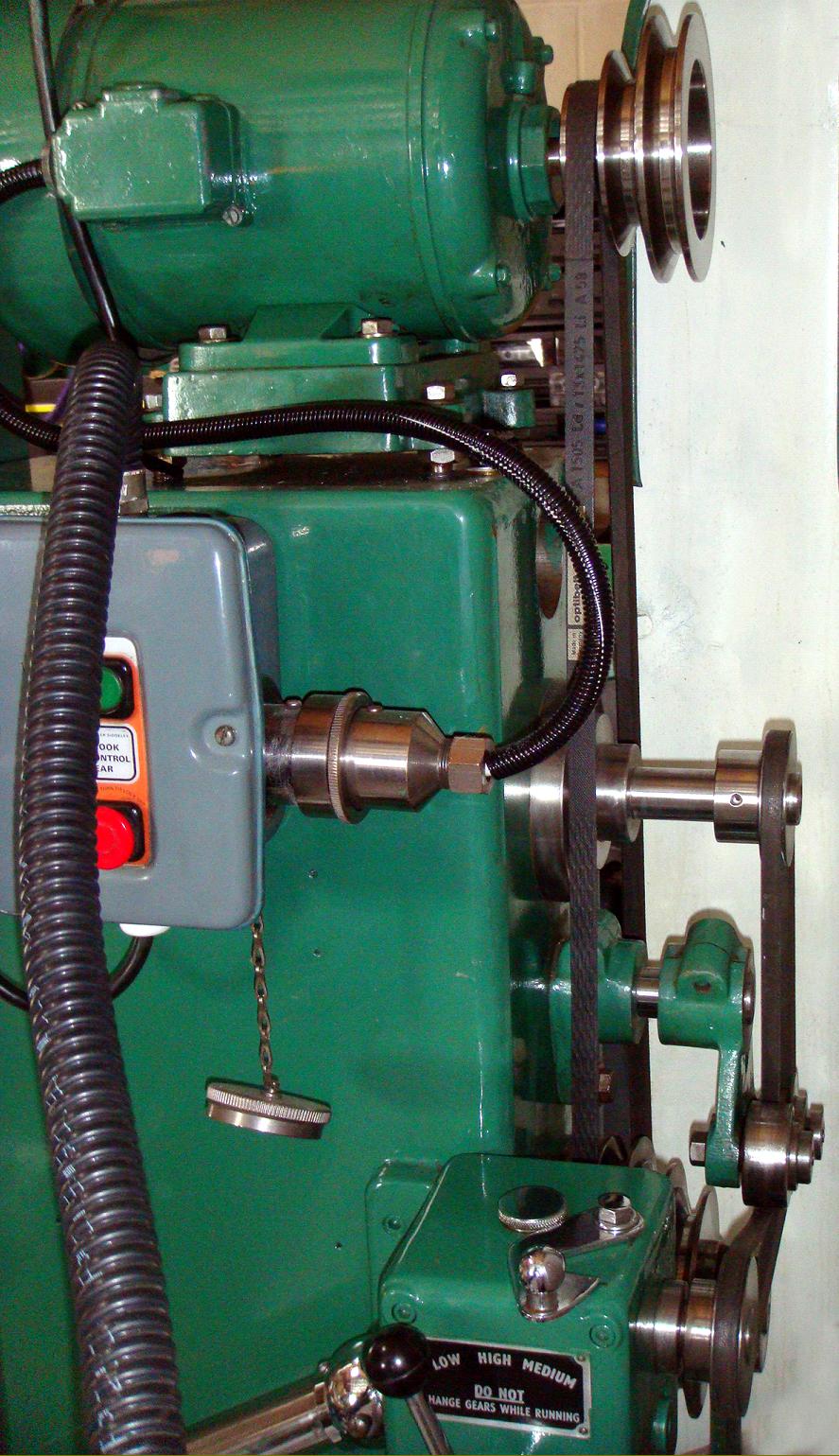

The motor on my mill had been swapped out for a bigger motor and the original pulley had been bored out. I have refurbished the original motor and want to put the original 3 way pulley back on. There is not enough meat in the pulley to use a taperlock bush so will be turning a sleeve, wall thickness will be approx 4mm.

Looking at the size of the old and the new they are probably 5/8" (circa 15.9mm) and 15/16" (circa 23.7mm) respectively and it needs to be just over 2" long. The mill motor/pulley is identical to

I will be cutting 2 key-ways in the sleeve and one in the pulley, not the full 2" and opposite sides of the sleeve. There is a grub screw in the smaller pulley.

I have both brass and aluminium rod handy, but will have to buy in some steel. If ali or brass is no good, what grade of steel is better for turning/boring?

Cheers

Andy

Looking at the size of the old and the new they are probably 5/8" (circa 15.9mm) and 15/16" (circa 23.7mm) respectively and it needs to be just over 2" long. The mill motor/pulley is identical to

I will be cutting 2 key-ways in the sleeve and one in the pulley, not the full 2" and opposite sides of the sleeve. There is a grub screw in the smaller pulley.

I have both brass and aluminium rod handy, but will have to buy in some steel. If ali or brass is no good, what grade of steel is better for turning/boring?

Cheers

Andy