You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best way to fix this motor

- Thread starter jimbo84

- Start date

Agroshield

Member

- Messages

- 6,382

See if you can open up the U-shaped bit that is folded over the wire. Solder into the base of the U. Close it up when finished.

Probably some JB Weld around it once tested as vibration might fracture it again.

I think they are made with the U's open, or maybe as L's and then bent over at the end of the winding process.

Probably some JB Weld around it once tested as vibration might fracture it again.

I think they are made with the U's open, or maybe as L's and then bent over at the end of the winding process.

Agroshield

Member

- Messages

- 6,382

They are not soldered originally.

But right now, the wire that was continuous when the item was manufactured, has a break in it. It is discontinuous. What alternatives to solder might there be for restoring its continuity?

Ok but what has the motor come out of out of interest?But right now, the wire that was continuous when the item was manufactured, has a break in it. It is discontinuous. What alternatives to solder might there be for restoring its continuity?

Nomad

Member

- Messages

- 2,300

- Location

- North Devon (for how long?)

As a tinkerer / DIY type ( not a motor expert) some ideas :

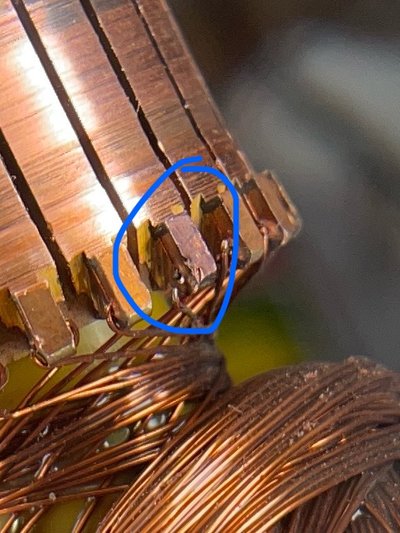

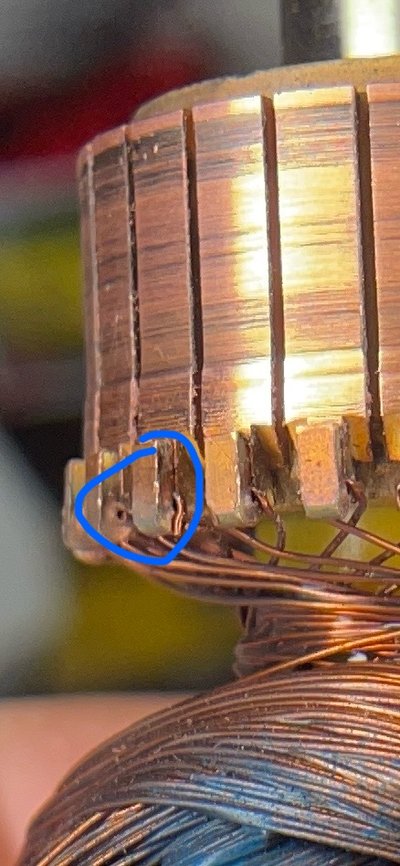

It's been crimped - open up the crimp to remove the broken end of the wire.

The wire originally over-shoots the crimp and connects from the left, will the snapped wire reach the crimp if you go direct and connect to the right side of the crimp?

Some of the other crimps have 2 wire connected ( looped in & out), the one in your photo looks to only have 1 (broken) wire - am I looking at it right?

It's been crimped - open up the crimp to remove the broken end of the wire.

The wire originally over-shoots the crimp and connects from the left, will the snapped wire reach the crimp if you go direct and connect to the right side of the crimp?

Some of the other crimps have 2 wire connected ( looped in & out), the one in your photo looks to only have 1 (broken) wire - am I looking at it right?

Ok but what has the motor come out of out of interest?

I was in need of a pendant drill, I took a punt on a box of bits as spares and repairs on ebay, this was one of the motors in the box.

A member on here kindly sorted me out with a working set up so the box of spares and repairs off ebay isn’t needed I’ve got one of the other items in the box working so I can sell that on to cover what I paid for the ebay box so this motor stands me at nothing.

They are quite spendy to buy new which is why I was hoping I might be able to repair it.

As a tinkerer / DIY type ( not a motor expert) some ideas :

It's been crimped - open up the crimp to remove the broken end of the wire.

The wire originally over-shoots the crimp and connects from the left, will the snapped wire reach the crimp if you go direct and connect to the right side of the crimp?

Some of the other crimps have 2 wire connected ( looped in & out), the one in your photo looks to only have 1 (broken) wire - am I looking at it right?

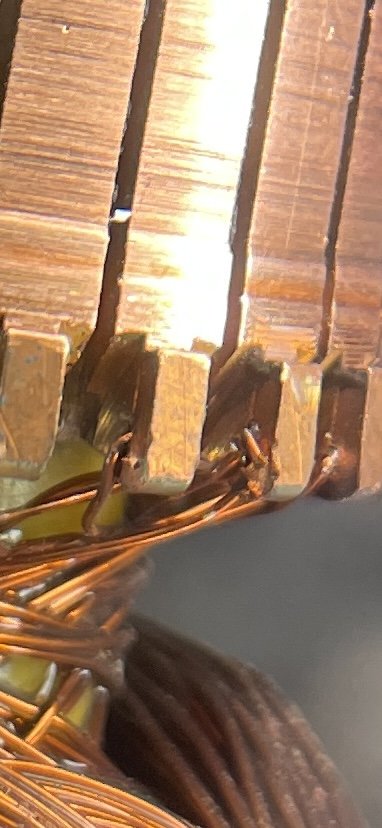

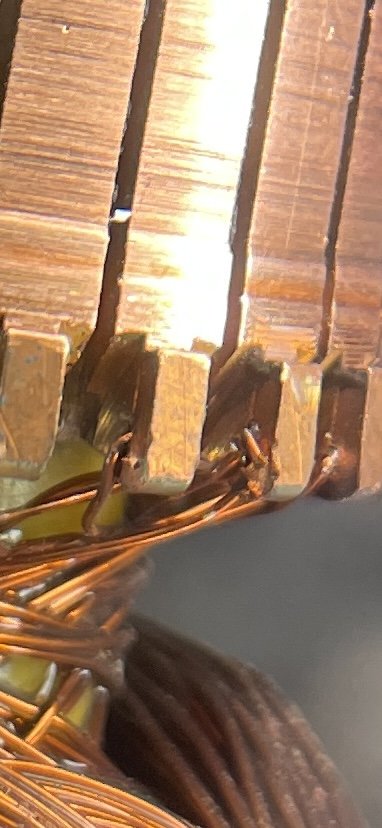

There isn’t enough slack on them to get them into the crimps enough, there’s just enough to get them to where they are broken. Even if I could pull a bit more on them I think the extra tension may just snap them again.

To add, there’s at least 3 broken.

I didn’t think of the heat, good point.Bear in mind the commutator gets hot. Something I never really factored in as a schoolboy when I rewound a motor for an RC car and soldered the triple windings in. Went like stink for all of about 30 seconds before it died a death . Autopsy showed it had thrown all the soft solder off the commutator. It seems Automotive starter motors etc that have soldered in windings are done with a higher temperature solder for this very reason…

I’ve had a bit of a look at this today. Bent down one of the clamps as suggested and bringing the cable in from the opposite side of the clamp to what it was originally seems to just give it enough slack.

I need to get some better magnification to be able to do this, my eyes are strained just from looking at it.

On closer inspection there are at least 13 snapped wires so I suspect FOD has made its way into the motor.

The vent is right where these snapped wires are. Some suspect damage to one of the wire clamps suggests this too.

I’m debating whether it’s worth the time and effort. One or two wires would be doable but this many seems hard work.

Open clamp with the wire coming in from the opposite side.

Damage

I need to get some better magnification to be able to do this, my eyes are strained just from looking at it.

On closer inspection there are at least 13 snapped wires so I suspect FOD has made its way into the motor.

The vent is right where these snapped wires are. Some suspect damage to one of the wire clamps suggests this too.

I’m debating whether it’s worth the time and effort. One or two wires would be doable but this many seems hard work.

Open clamp with the wire coming in from the opposite side.

Damage

Agroshield

Member

- Messages

- 6,382

Perhaps send this person an enquiry and see if they have any suggestions or can offer an economic repair:

Thanks for the link. I'll send him an email and see what they think.Perhaps send this person an enquiry and see if they have any suggestions or can offer an economic repair: