MattH

Member

- Messages

- 4,515

- Location

- Cornwall

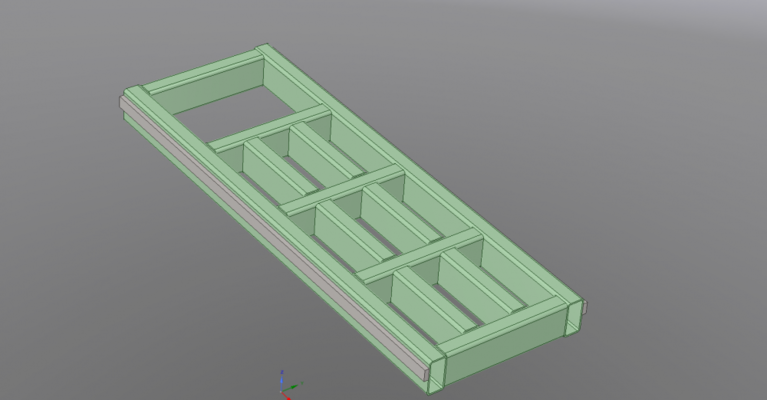

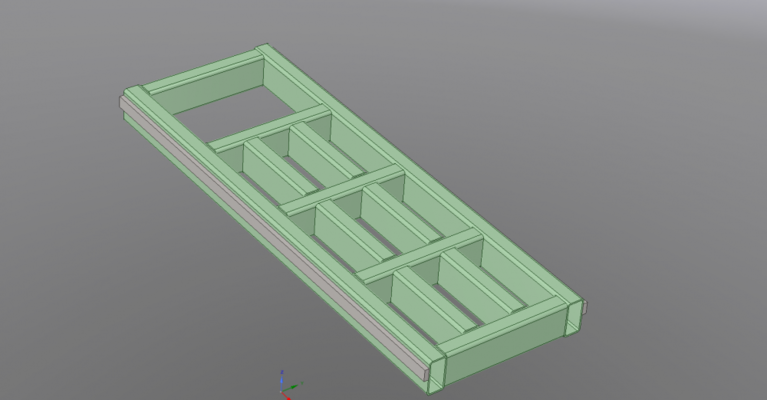

I need to weld this structure and would like advise on how to minimise distortion and the best process to use?

The important factors are that the long box sections remain as parallel and straight as possible and that the entire structure remains as flat and level as can be.

The overall size is 550mm wide and 1600mm long.

The long side boxes will have a piece of 15x40mm flat bar welded down their length but will then be machined back to true and straight before welding.

The box will be 120mmx60mmx5mm wall thickness. I have 150A MIG and a 160A DC/AC MMA available. I was thinking of tacking up with the MIG and then using the Arc to complete all the welds.

I have a 24" square cast iron surface plate that I can use to clamp to and jig up the pieces (only half the structure at a time though due to the length).

I know the MIG doesn't have the power for full penetration but that is not necessarily required, this structure will not be load bearing. It just needs to be stiff and true.

The important factors are that the long box sections remain as parallel and straight as possible and that the entire structure remains as flat and level as can be.

The overall size is 550mm wide and 1600mm long.

The long side boxes will have a piece of 15x40mm flat bar welded down their length but will then be machined back to true and straight before welding.

The box will be 120mmx60mmx5mm wall thickness. I have 150A MIG and a 160A DC/AC MMA available. I was thinking of tacking up with the MIG and then using the Arc to complete all the welds.

I have a 24" square cast iron surface plate that I can use to clamp to and jig up the pieces (only half the structure at a time though due to the length).

I know the MIG doesn't have the power for full penetration but that is not necessarily required, this structure will not be load bearing. It just needs to be stiff and true.