Hi

My neighbour where I work does metal fabircation (beams, structures etc etc) and he is having all the staff tested. I don't know what the test is called I will find it out tomorrow for you when they get in.

They are having issue with the weld cracking when tested and aren't sure what they are doing wrong so I suggested to post it on here for them just trying to help them.

10mm mild steel

1mm wire

35 degree vee

2mm gap between joints

they are using about 190amps on a cebora mig

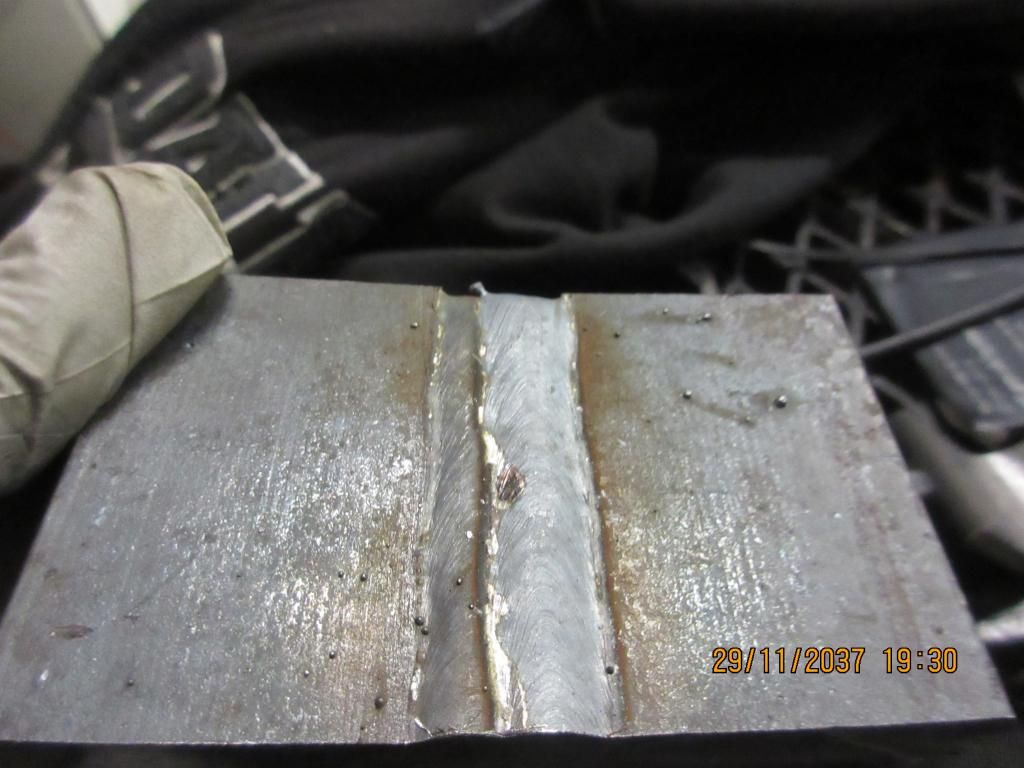

see the fracture

Fracture

Same piece

After welding

How it looks after welding

Profile

Bottom of the weld

Just some testing of welds etc but you can see the workpiece

Any ideas what is wrong guys? If you need more info let me know and i'll find out.

Thanks

My neighbour where I work does metal fabircation (beams, structures etc etc) and he is having all the staff tested. I don't know what the test is called I will find it out tomorrow for you when they get in.

They are having issue with the weld cracking when tested and aren't sure what they are doing wrong so I suggested to post it on here for them just trying to help them.

10mm mild steel

1mm wire

35 degree vee

2mm gap between joints

they are using about 190amps on a cebora mig

see the fracture

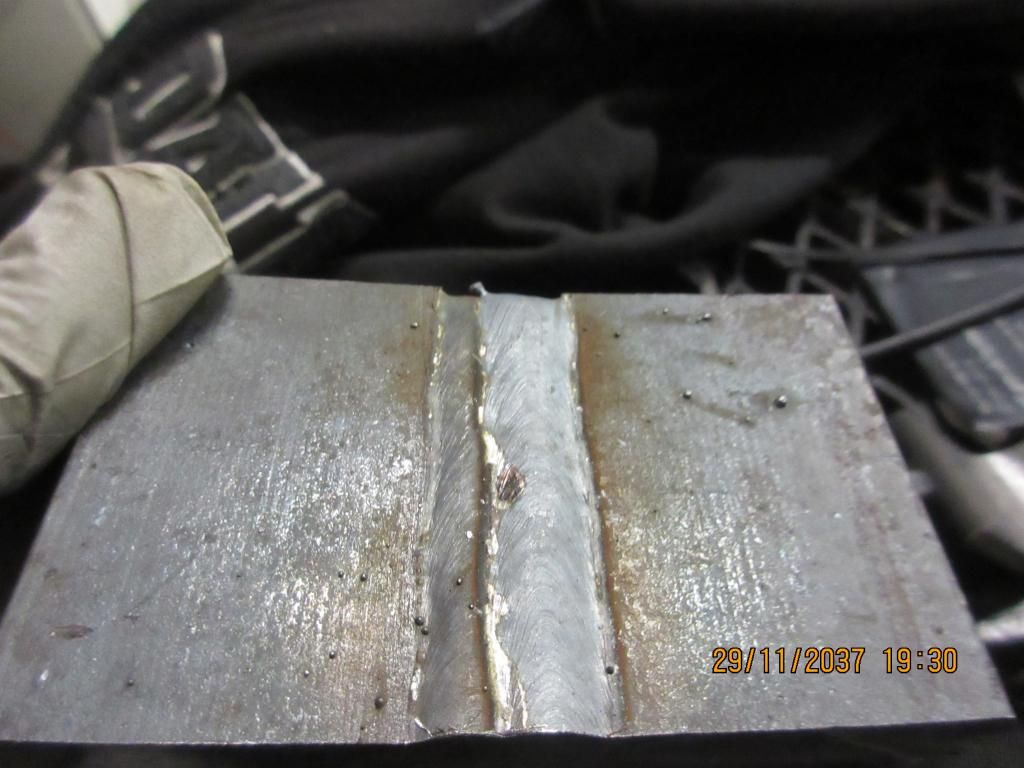

Fracture

Same piece

After welding

How it looks after welding

Profile

Bottom of the weld

Just some testing of welds etc but you can see the workpiece

Any ideas what is wrong guys? If you need more info let me know and i'll find out.

Thanks