Memmeddu

Member

- Messages

- 4,753

- Location

- Italia Sardegna

So since I'm in lockdown with absolutely nothing to do I was wondering about learning more about carbon arc brazing .

I've read various threads online about this technique but I didn't completely understand how it works

This thread would be meant to put together some knowledge about prior starting another thread in the projects section where I will cover the building of the torch .

So what I've understood is that a buzz box would be the preferred power source for this process , someone says that an inverter welder would work but AC is better in this case (heaven electrodes consumption)

Current settings way lower than carbon arc gouging so my little buzz box would be enough (200A)

But I can't understand which size of electrodes and current settings I would need to use (heating stuff for bending)

Another thing I was reading about is eyes protection

Which shade I should use?

About this I'm thinking to get a traditional aulekro helmet (with double glasses and pc clear lenses inside)

Construction wise I'm searching out for various designs and trying to understand which one would be the best

The clamp holder design seems to be the easiest way to make a torch

This involves a kind of clamp that when is compressed will make the carbons touch together and start the arc

There is also the slide design

This involves to use a sliding element on the handle to adjust the distance between the tips of the carbon electrodes

Another design is the "Lincoln style?" I've seen Lincoln electric arc brazing torches online and those use a mechanism which turns the rod holders to adjust the distance between the rods

This design is the most complex but also the most elegant I might say

Heat shield useful or not?

I've seen some torches use a kind of heat shield between the Arc and the handle ,some others don't .

The rod holders

Various possibility here to make them

But what to use?

Copper isn't an option (too much expensive and hard to find here)

Alluminum tubing (I have some) but the parts that hold the electrode would be steel

So steel might be easier to work with , cheaper , and I can weld it .

Steel rods o steel tubing

Steel rods are easier to weld

Steel tubing I could put the copper strands inside of it

So essentially a lot things in mind but actually not clue of how to proceed

I can buy one already made but where's the satisfaction to use something Made with your hands ?

Thanks in advance and sorry for the long thread object

I've read various threads online about this technique but I didn't completely understand how it works

This thread would be meant to put together some knowledge about prior starting another thread in the projects section where I will cover the building of the torch .

So what I've understood is that a buzz box would be the preferred power source for this process , someone says that an inverter welder would work but AC is better in this case (heaven electrodes consumption)

Current settings way lower than carbon arc gouging so my little buzz box would be enough (200A)

But I can't understand which size of electrodes and current settings I would need to use (heating stuff for bending)

Another thing I was reading about is eyes protection

Which shade I should use?

About this I'm thinking to get a traditional aulekro helmet (with double glasses and pc clear lenses inside)

Construction wise I'm searching out for various designs and trying to understand which one would be the best

The clamp holder design seems to be the easiest way to make a torch

This involves a kind of clamp that when is compressed will make the carbons touch together and start the arc

There is also the slide design

This involves to use a sliding element on the handle to adjust the distance between the tips of the carbon electrodes

Another design is the "Lincoln style?" I've seen Lincoln electric arc brazing torches online and those use a mechanism which turns the rod holders to adjust the distance between the rods

This design is the most complex but also the most elegant I might say

Heat shield useful or not?

I've seen some torches use a kind of heat shield between the Arc and the handle ,some others don't .

The rod holders

Various possibility here to make them

But what to use?

Copper isn't an option (too much expensive and hard to find here)

Alluminum tubing (I have some) but the parts that hold the electrode would be steel

So steel might be easier to work with , cheaper , and I can weld it .

Steel rods o steel tubing

Steel rods are easier to weld

Steel tubing I could put the copper strands inside of it

So essentially a lot things in mind but actually not clue of how to proceed

I can buy one already made but where's the satisfaction to use something Made with your hands ?

Thanks in advance and sorry for the long thread object

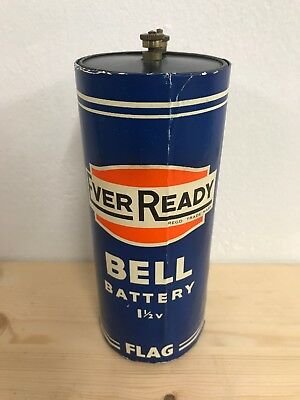

I also remember the ones sold as a kit that could be used straight off a truck battery

I also remember the ones sold as a kit that could be used straight off a truck battery