Just got my hands on a cheap Cebora 150 DC TIG... Im brand new to TIG so bare with me....

First off I thought i would turn it on (without gas) just to see if it was fit and healthy and could at least strike an ARC... So when i fired it up and struck the grounded work it would burst into a load of sparks just like a stick arc would, it would do this once only and i would have to switch the machine off and back on again to do this again...

So anyway i opened up the machine and the first thing i noticed was that the largest relay upon its own pcb at the back of the machine wasnt opening or closing when i either struck an arc or pulled the torch trigger. I figured it probably should, so i decided to hold it closed myself with a plastic pen and now when i try to scratch start an arc i dont get a burst of sparks like previous, infact when i touch the workpiece I get loads of little teeny weeny sparks that are completely quiet, and seem to fizz arround the tip radiating out about 5mm, plus I can actually lift the tip now and get it to start a teeny bright blue arc, which is very very weedy to say the least, any more than 1-2mm lift and it dies and its absolutely tiny, doesnt light up the area like a good strong arc on other tigs ive seen actually do... Also when i lower or raise the front curretn dial it does nothing to make this arc weaker or stronger at all.

BARE IN MIND IM JUST TESTING THIS THING AND SO FAR IVE NO GAS AT ALL, I JUST WANT TO VERIFY IT IS A CAPABLE MACHINE BEFORE SPENDING ON REGULATOR, FLOW METER AND GAS BOTTLE..

So basicaly I am going to go through each of the seperate pcb boards and test and elliminate any fault if i hopefully come accross one.

So first off can anyone help identify each of the pcbs ive got withing my machine, heres the pics below, this will help me no end.

So heres the pcbs from this machine that ive removed to test.

First off this board below has a big capacitor and some power resistors, plus a square capacitor and not sure what the purpose of this boards for? All components on this board tested fine out of circuit.

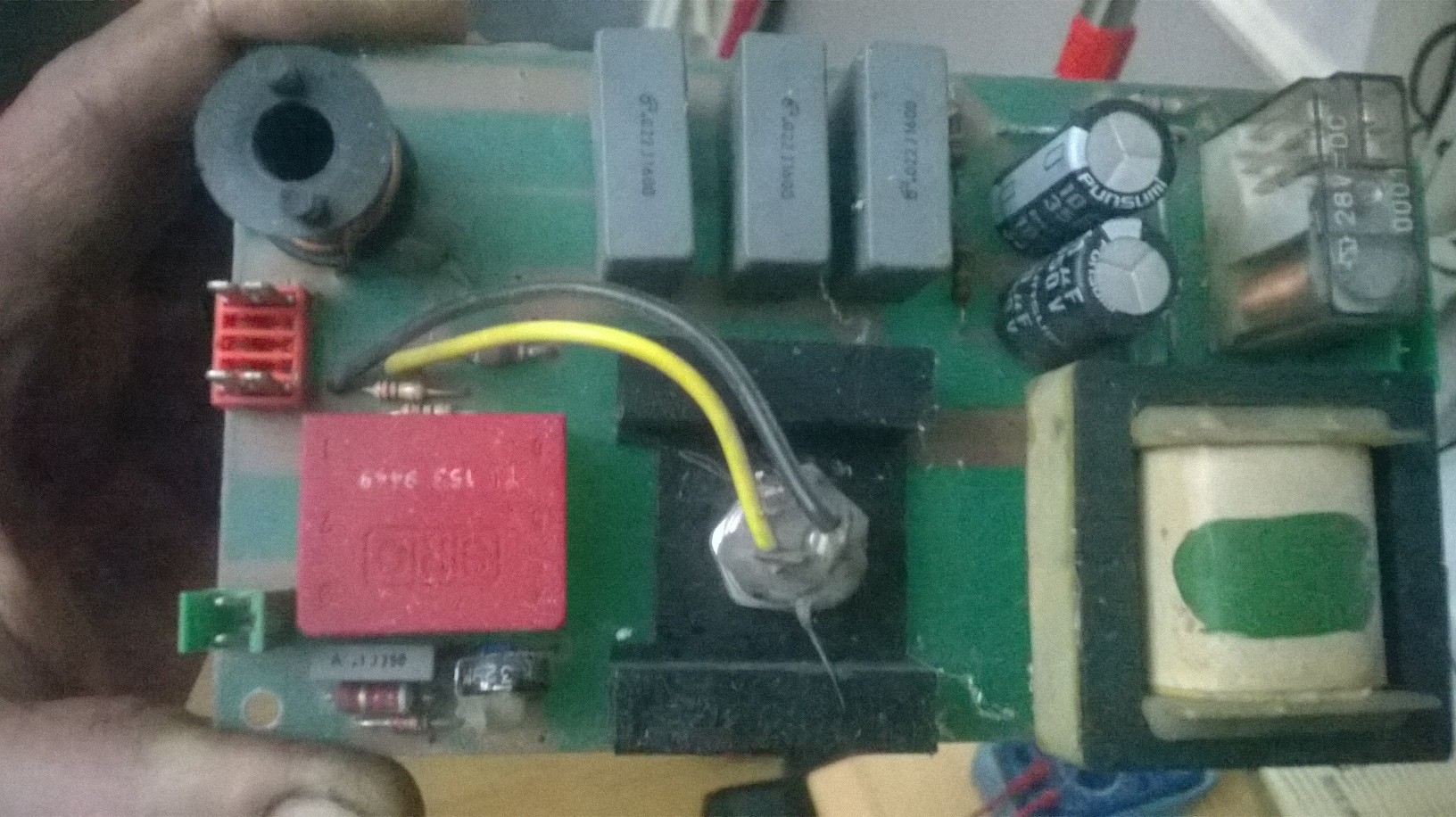

Next the board below im going to hazzard a guess is something to do with the arc that the welder produces and the only reason ive come to this conclusion is because when i was searching tinternet to identify all the components i found out that the red square thing is what they call a pulse transformer. So me and my wisdom figured this is something to do with a HF start or maybe some pulse required to hold the arc when in use? Im likely wrong, but hey.... Im sure you guys will straighten me oot..

Oh also i learnt about Theyristors because of this pcb today, I honest thought the studded silver thing sat on the big black heatsink was some kind of power diode like what you find on the plates of a mig welders rectifier arrangement. but when testing it as a diode it wasnt testing right and i thought I had a duff rectifier, so in my search for a new one i obviously learnt these are actually Thyristors or SCR's and this one out of circuit tested just fine. I tested the resistors, the caps but i havent done the transformers, i really didnt want to take them outa circuit and mess on, i figured i can do some tests whilst the machine is on and test for voltages.

I havent tested the relay on this board just yet, ive not yet sorted a 24vdc source to do so.

Now this is the main relay below that im having to hold closed to eneable the machine to even try to make an arc. the diodes tested fine, though again i need to sort a few batteries in the morning to make a 24vdc source and i will test all relays.

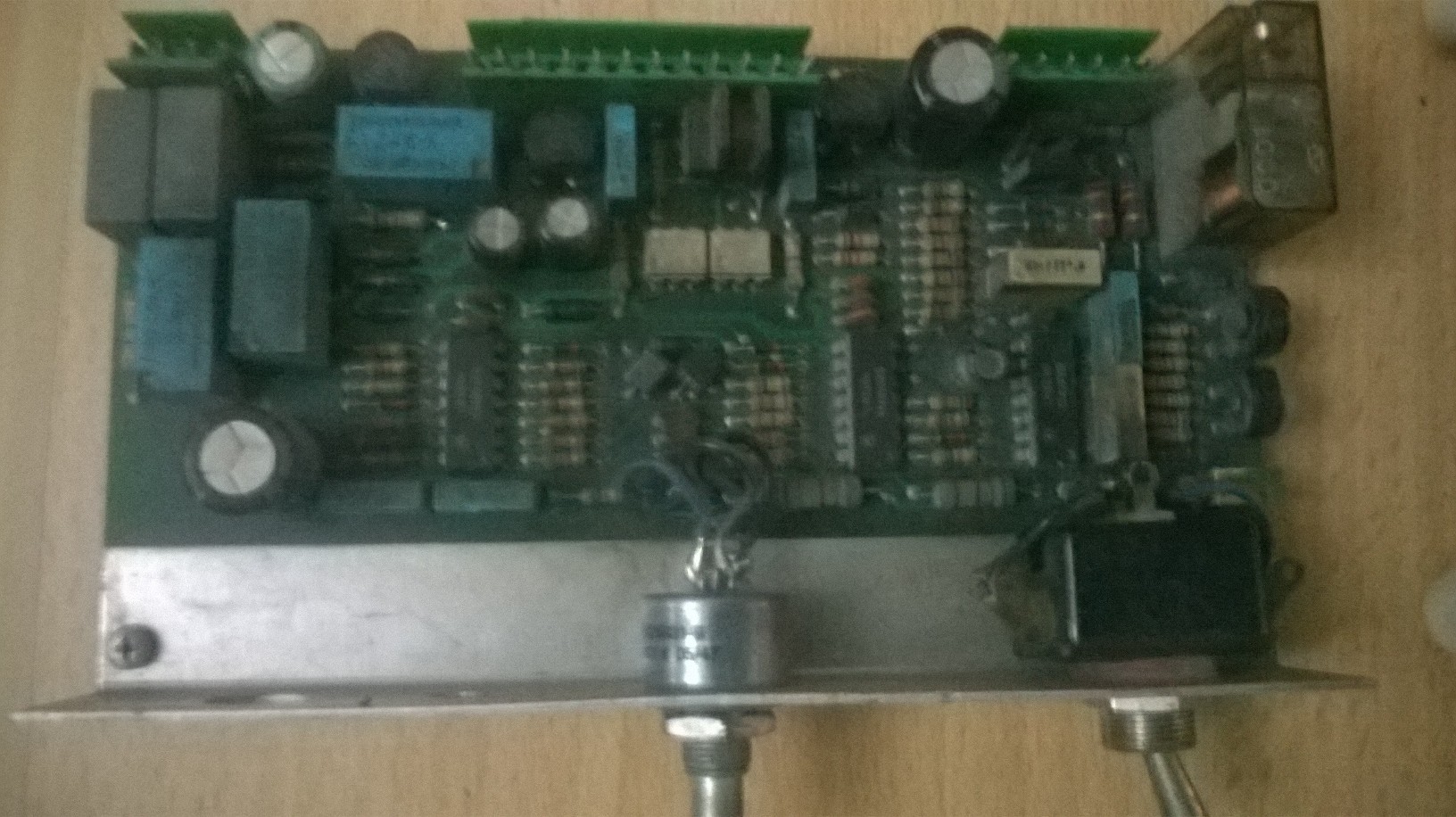

Below is the main pcb. Only tested the black 3, 4-pin bridge rectifiers.. which tested fine. I will get round to testing the blue relays once i sort a 24vdc source, also the clear relay in the top right, the black chips are texas instruments OP Amps and there are 2x LM339N and 1x LM324W.

Below is the main pcb. Only tested the black 3, 4-pin bridge rectifiers.. which tested fine. I will get round to testing the blue relays once i sort a 24vdc source, also the clear relay in the top right, the black chips are texas instruments OP Amps and there are 2x LM339N and 1x LM324W.

The 2x little white chips in the center I havent a clue what they are and cant read them just yet, need to source a magnify glass in morning...

One last thing like i was saying the machine didnt seem to increase or decrease the arc strength when i turned the current dial, BUT! the dial/potentiometer here has tested fine....

First off I thought i would turn it on (without gas) just to see if it was fit and healthy and could at least strike an ARC... So when i fired it up and struck the grounded work it would burst into a load of sparks just like a stick arc would, it would do this once only and i would have to switch the machine off and back on again to do this again...

So anyway i opened up the machine and the first thing i noticed was that the largest relay upon its own pcb at the back of the machine wasnt opening or closing when i either struck an arc or pulled the torch trigger. I figured it probably should, so i decided to hold it closed myself with a plastic pen and now when i try to scratch start an arc i dont get a burst of sparks like previous, infact when i touch the workpiece I get loads of little teeny weeny sparks that are completely quiet, and seem to fizz arround the tip radiating out about 5mm, plus I can actually lift the tip now and get it to start a teeny bright blue arc, which is very very weedy to say the least, any more than 1-2mm lift and it dies and its absolutely tiny, doesnt light up the area like a good strong arc on other tigs ive seen actually do... Also when i lower or raise the front curretn dial it does nothing to make this arc weaker or stronger at all.

BARE IN MIND IM JUST TESTING THIS THING AND SO FAR IVE NO GAS AT ALL, I JUST WANT TO VERIFY IT IS A CAPABLE MACHINE BEFORE SPENDING ON REGULATOR, FLOW METER AND GAS BOTTLE..

So basicaly I am going to go through each of the seperate pcb boards and test and elliminate any fault if i hopefully come accross one.

So first off can anyone help identify each of the pcbs ive got withing my machine, heres the pics below, this will help me no end.

So heres the pcbs from this machine that ive removed to test.

First off this board below has a big capacitor and some power resistors, plus a square capacitor and not sure what the purpose of this boards for? All components on this board tested fine out of circuit.

Next the board below im going to hazzard a guess is something to do with the arc that the welder produces and the only reason ive come to this conclusion is because when i was searching tinternet to identify all the components i found out that the red square thing is what they call a pulse transformer. So me and my wisdom figured this is something to do with a HF start or maybe some pulse required to hold the arc when in use? Im likely wrong, but hey.... Im sure you guys will straighten me oot..

Oh also i learnt about Theyristors because of this pcb today, I honest thought the studded silver thing sat on the big black heatsink was some kind of power diode like what you find on the plates of a mig welders rectifier arrangement. but when testing it as a diode it wasnt testing right and i thought I had a duff rectifier, so in my search for a new one i obviously learnt these are actually Thyristors or SCR's and this one out of circuit tested just fine. I tested the resistors, the caps but i havent done the transformers, i really didnt want to take them outa circuit and mess on, i figured i can do some tests whilst the machine is on and test for voltages.

I havent tested the relay on this board just yet, ive not yet sorted a 24vdc source to do so.

Now this is the main relay below that im having to hold closed to eneable the machine to even try to make an arc. the diodes tested fine, though again i need to sort a few batteries in the morning to make a 24vdc source and i will test all relays.

The 2x little white chips in the center I havent a clue what they are and cant read them just yet, need to source a magnify glass in morning...

One last thing like i was saying the machine didnt seem to increase or decrease the arc strength when i turned the current dial, BUT! the dial/potentiometer here has tested fine....