Hi

I bought a SE15C150 on Friday, the seller said it needed a new motor after it was checked out by a sparky. I've taken the motor apart and it's very clean inside, I've measured the resistance of the coils - 2.3, 0.8 and 3.1 ohms, the two smaller value's added together should give the resistance of the third which it does.

I can only presume that it's failed an insulation resistance test, I'm hoping I can borrow a Megger tester and test it out myself. It's a 230V motor and I read that it should be tested at 500V DC, someone mentioned applying the test voltage for 60 second's before measuring the resistance and others have just measured the resistance straight off so I'm not sure what's correct?

I've been stripping the pump down and there are some differences to the SE16C150 which gasket999 rebuilt four year's ago.

Only one crankshaft bearing at the pulley end, a bush at the other end. No big end cap so the connecting rods will have to slip off the end of the crank.

How to remove the crankshaft, press it out from the bush end?

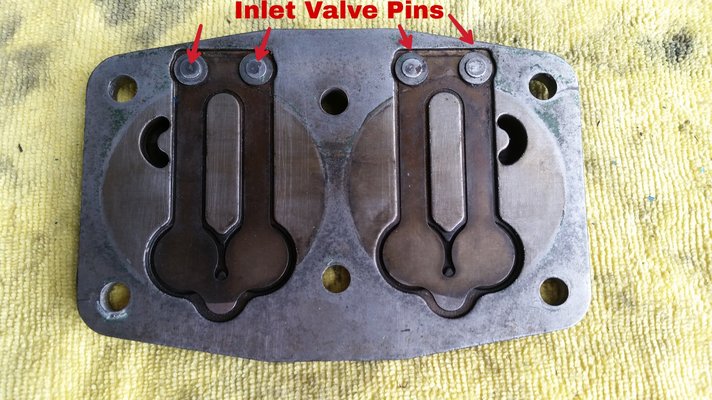

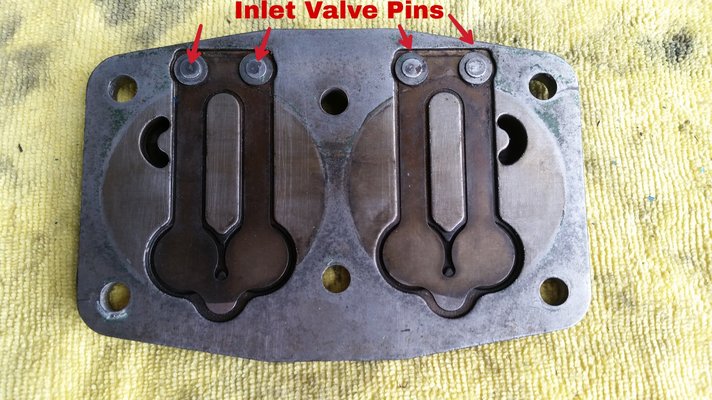

Also, the inlet valves are pinned onto the valve plate. I was thinking about grinding off the heads and knocking the pins out, I can then tap the holes and use some stainless socket head screws to fit them back on.

I bought a SE15C150 on Friday, the seller said it needed a new motor after it was checked out by a sparky. I've taken the motor apart and it's very clean inside, I've measured the resistance of the coils - 2.3, 0.8 and 3.1 ohms, the two smaller value's added together should give the resistance of the third which it does.

I can only presume that it's failed an insulation resistance test, I'm hoping I can borrow a Megger tester and test it out myself. It's a 230V motor and I read that it should be tested at 500V DC, someone mentioned applying the test voltage for 60 second's before measuring the resistance and others have just measured the resistance straight off so I'm not sure what's correct?

I've been stripping the pump down and there are some differences to the SE16C150 which gasket999 rebuilt four year's ago.

Only one crankshaft bearing at the pulley end, a bush at the other end. No big end cap so the connecting rods will have to slip off the end of the crank.

How to remove the crankshaft, press it out from the bush end?

Also, the inlet valves are pinned onto the valve plate. I was thinking about grinding off the heads and knocking the pins out, I can then tap the holes and use some stainless socket head screws to fit them back on.

Last edited: