I've decided that I might as well plumb in my new compressor with 1/2" copper to help with air temp/water vapour when spray painting down the road.

I'm planning to solder where possible (exceptions being ball valves and tees).

I know that horizontal piping should be angled down slightly (min. 1 in 100) with the flow of air; is this achieved while using normal 90deg elbows? I ask because other than 45deg elbows I can't see anything in between and I don't want to crack the solder and cause leaks by forcing an angle.

I'm planning to solder where possible (exceptions being ball valves and tees).

I know that horizontal piping should be angled down slightly (min. 1 in 100) with the flow of air; is this achieved while using normal 90deg elbows? I ask because other than 45deg elbows I can't see anything in between and I don't want to crack the solder and cause leaks by forcing an angle.

I have a few pics if you would like me to write up in a pm.

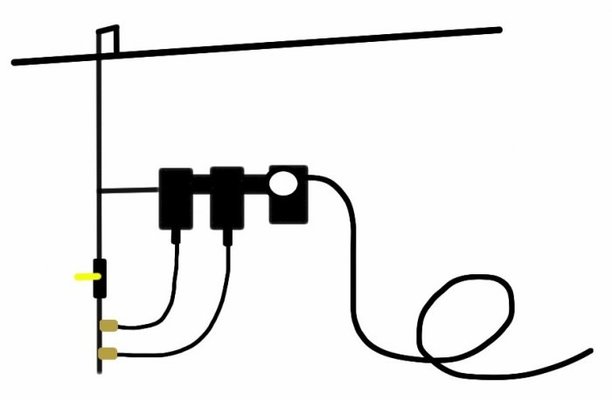

I have a few pics if you would like me to write up in a pm. The upside is that it simplifies the piping such that I really only need one run with drains at each end. I'll tee off the main line as normspanners suggested into a filter/reg then QR.

The upside is that it simplifies the piping such that I really only need one run with drains at each end. I'll tee off the main line as normspanners suggested into a filter/reg then QR.