i was recently asked by a friend to make a set of stands to raise his cornerweight pads up off the floor 300/400mm so he can use his 2 post lift to raise/lower the car onto them and work at a nicer height...

a bit like these:

http://www.demon-tweeks.co.uk/oncirrus/system/trans.png

but higher....

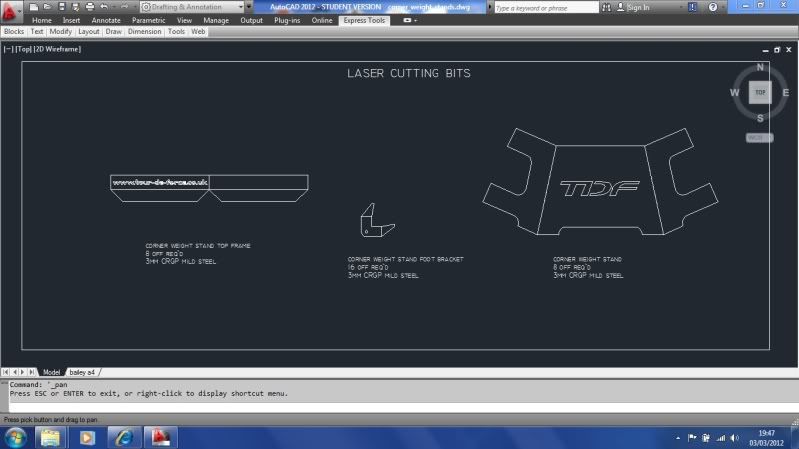

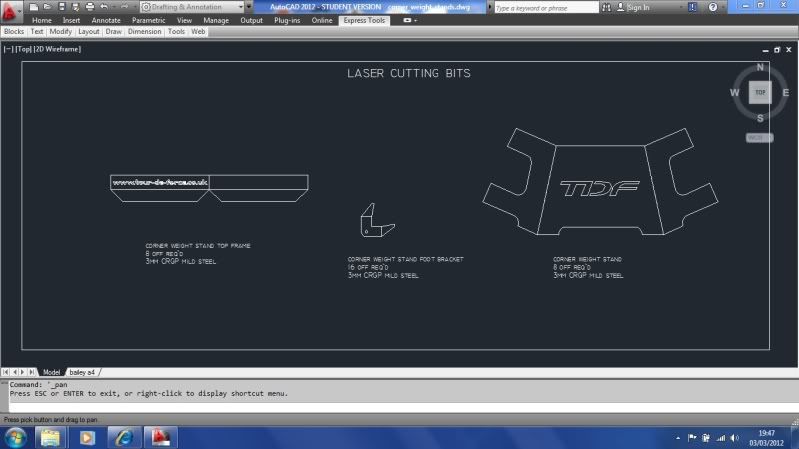

so i set about having a play on autocad, he`s just launched a re-vamped website so i thought it`d be nice to incorporate his logo/website in the same font... (bit of a PITA transfering JPEG into DWG format but i got there in the end and fired this over to my local laser profilers:

3 days later and 30 minutes on the press i had the building blocks:

fired up the tig and got them all tacked up:

really pleased with the quality of the cutting:

then came the bit i was dreading....

MIG`ing them up, i make no excuses i fecking hate MIG welding, its dirty, smelly, and i`m no good at it hahahaha

fortunatly luck was on my side and things went ok:

a quick hunt on Ebay sourced some M10 feet and the stands were ready for delivery and powdercoat * :

*- well, not quite finished, i had to holesaw a 35mm hole in the top flange of each stand for the power wire to pass through....

and thats about it, putting the feet inside the corners rather than outside would have been easier, and probably stronger but then they wouldn`t be stackable, and i know workshop space is precious so went this route instead..

will get a final pic once there powdered....

Stu

a bit like these:

http://www.demon-tweeks.co.uk/oncirrus/system/trans.png

but higher....

so i set about having a play on autocad, he`s just launched a re-vamped website so i thought it`d be nice to incorporate his logo/website in the same font... (bit of a PITA transfering JPEG into DWG format but i got there in the end and fired this over to my local laser profilers:

3 days later and 30 minutes on the press i had the building blocks:

fired up the tig and got them all tacked up:

really pleased with the quality of the cutting:

then came the bit i was dreading....

MIG`ing them up, i make no excuses i fecking hate MIG welding, its dirty, smelly, and i`m no good at it hahahaha

fortunatly luck was on my side and things went ok:

a quick hunt on Ebay sourced some M10 feet and the stands were ready for delivery and powdercoat * :

*- well, not quite finished, i had to holesaw a 35mm hole in the top flange of each stand for the power wire to pass through....

and thats about it, putting the feet inside the corners rather than outside would have been easier, and probably stronger but then they wouldn`t be stackable, and i know workshop space is precious so went this route instead..

will get a final pic once there powdered....

Stu