I have made a couple of modifications to my CUT50p pilot arc plasma cutter and thought I would share. If nothing else please have a look at modification number one as there is a safety issue I found on mine and could affect others, I have seen others on here that have found similar with their cheap Chinese kit.

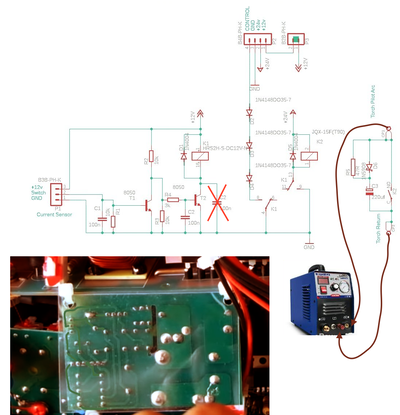

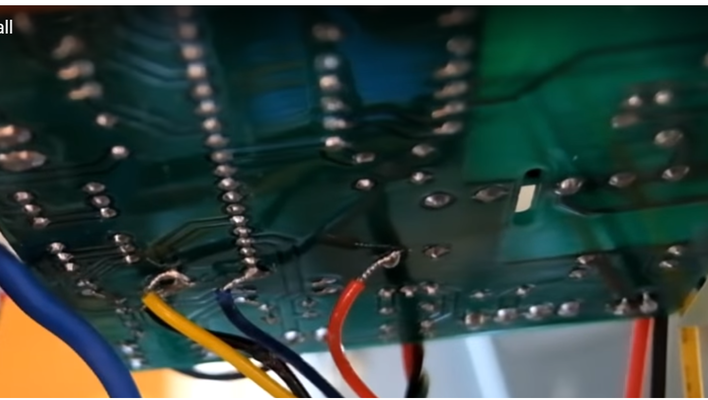

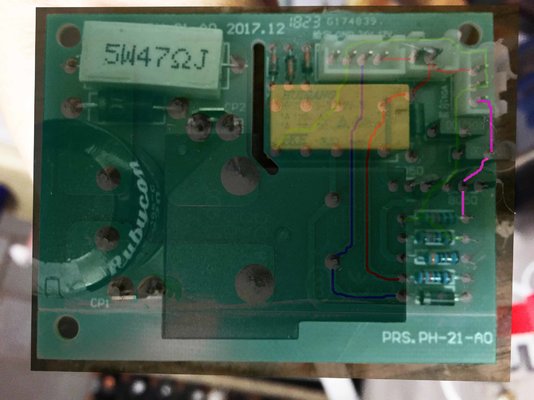

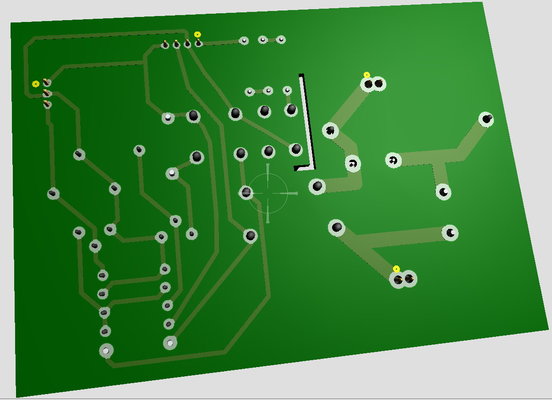

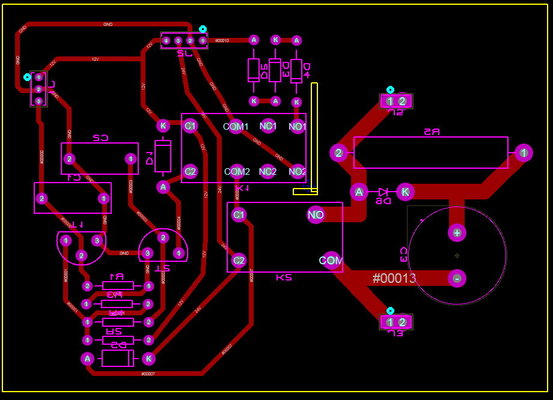

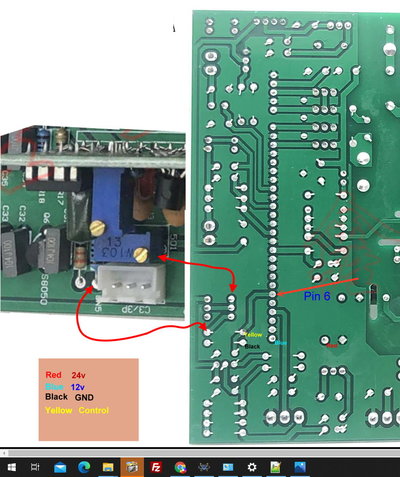

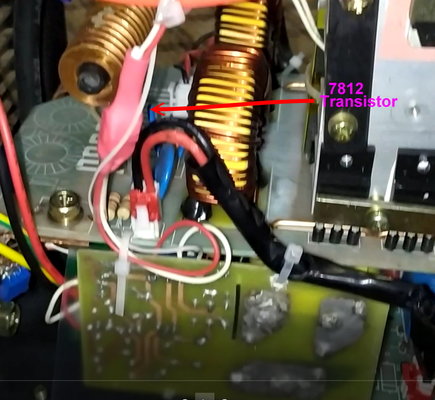

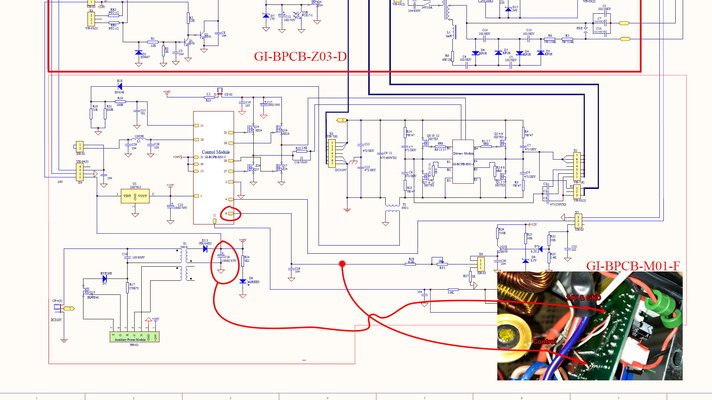

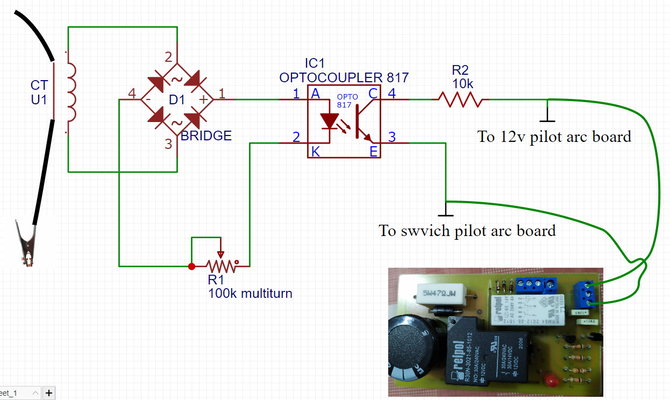

I bought the plasma cutter knowing its limitations, build quality and its warranty would be more or less non-existent, the modifications I have done will have blown away any chance of a warranty claim if there was any. Before I get into too much detail the usual safety warning if you don’t know what you are doing don’t attempt this, there are capacitors on the boards which charge up to high voltages and can remain like this for a long time after power is removed. I dropped the add in pilot arc board on a steel bench and the capacitor rated at 250V made quite a spark and it had been disconnected from the mains for at least 4 weeks. The plasma cutter I bought looked like below, the two things I didn’t like were the impossibly short mains lead with a dodgy plug on the end and the pilot arc connection, I therefore decided to change the torch connector to a Trafimet type one. It is my firm belief that the pilot arc was an addition to the original design, this is backed up by the poor way the pilot arc board is fitted, more on this later. This modification won’t make your plasma cutter perform any better, I just really hated the pilot arc connection I guess that is just me.

Modification 1

If your plasma cutter or cheap welder has a normal 13A plug check the fuse, I found below under the fuse carrier that had been hot melt glued in.

If you have this cut the plug off chuck it away and either stick a standard 13A fused plug or a 16A industrial plug on the end. I was quite impressed that they had managed to solder such a large piece of copper in without melting the plastic plug body. For me the only 16A plug I have feeds the compressor and I needed to plug it into a 32A feed I use on my Mig, wasn’t convinced the internal wiring was up to a 32A supply so fitted this with a 16A type C MCB.

Modification 2

My second modification concerns that pilot arc connection I hated, I purchased a Trafimet Central type connector from Aliexpress, cost me around £23 delivered for both plug and socket if you are looking for one search for “fy0023”. What I got looked like below but also included a springy cable strain relief and disconnect tool this is shown in a picture later.

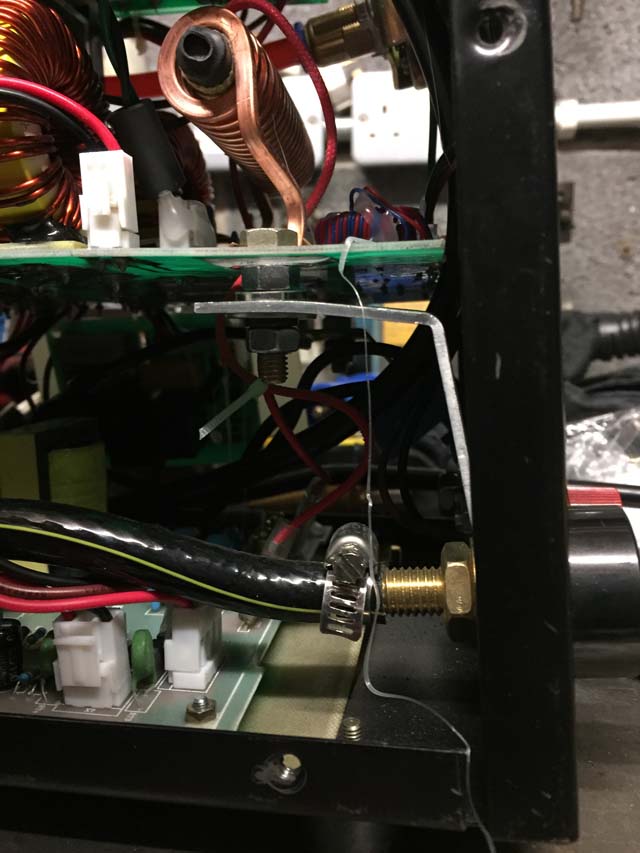

The existing torch connection looks like this

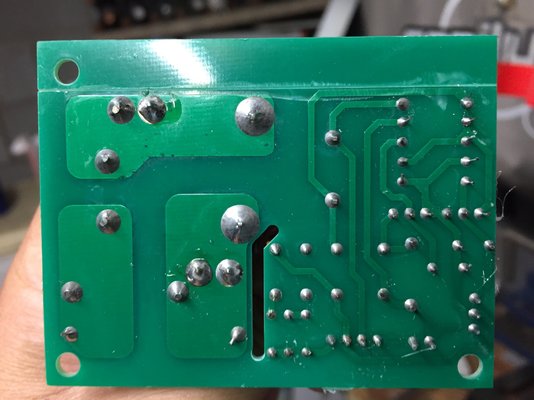

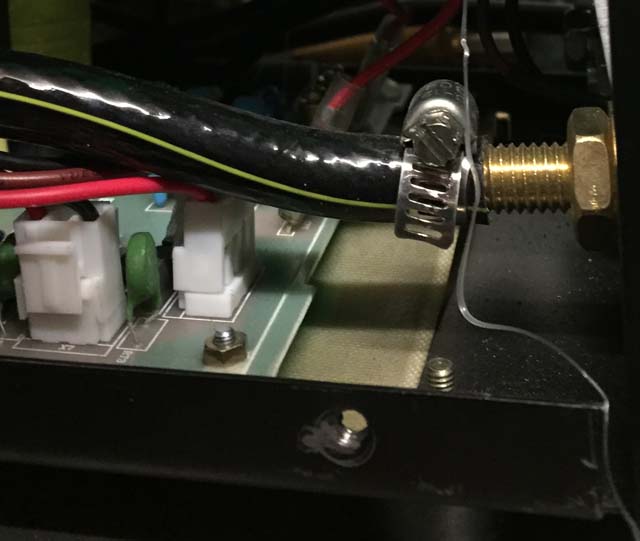

And once removed like this

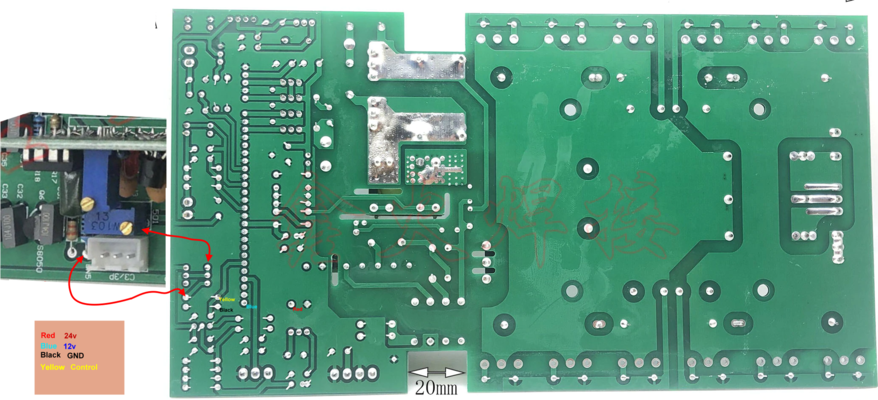

The whole front panel can be removed to make it easier by disconnecting the electrical connections, you’ll need to peel off the hot melt glue from the plugs after making a note of where everything goes and undoing 3 screws on the base. The new connector has a larger hole, I opened mine up to 30mm which covered the original anti-rotation lug holes, the new connector also has a single anti-rotation lug and I just added this with a file after drilling out. If I was doing again I would consider moving the new connector up, you will notice from below that the air hose is very close to the PCB connector on the original torch connection. The new connector is longer and the front panel slopes slightly back and interfered with the PCB connector. I only realised this after and got around it by unsoldering the connector from the PCB and soldering the wires directly into the PCB.

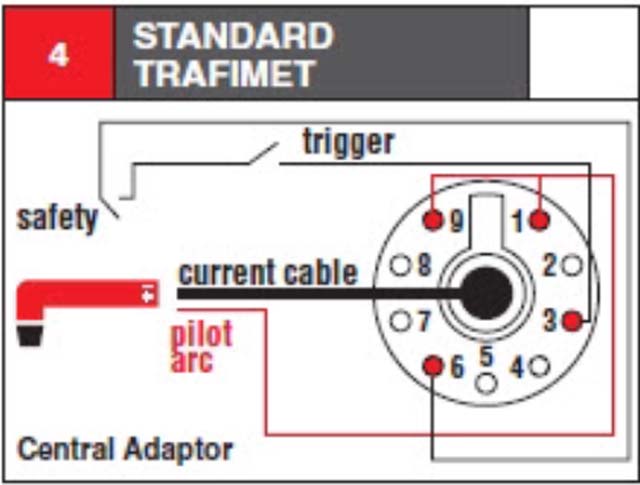

There appears to be many pin out variants on the way you connect these Trafimet connectors, from the Trafimet catalogue I decided to use the Trafimet standard pin out as below.

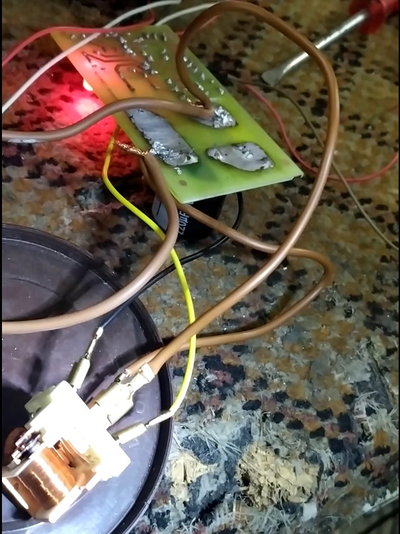

Once fitted the connector looked like below, the switch wires are soldered and heat shrink insulated, the two pilot arc connections from the Trafimet connector has been removed from the red pilot arc terminal and soldered to the two blue components and the thicker wire which goes off to the pilot arc board. There are spare wires on the Trafimet I left disconnected but available for use if needed.

The main plasma connection to the PCB is via an aluminium bracket, I had to manufacture a new one as the dimensions are different and the hole was bigger. The air hose connector is smaller than the original (6mm), I slid a small piece of tube over first to pad it out and tightened the jubilee clip.

The torch connector is show below it has a ¼ BSPP male thread for the main connection and is supplied with an adaptor to M12 female. I think the original plasma connector is M16, I made an adaptor out of the original front panel connector 1/4bsp to M16, I wouldn’t recommend this, and there is plenty of room in the connector for an adapter. The pilot arc and switch connections are via push in pins, I guess you need a specific crimp tool for these which most won’t have, the pins need to remain circular when fitted so I soldered my wires into the pins. The pins just seem to push in and not lock in unless there is a trick to.

To be continued

I bought the plasma cutter knowing its limitations, build quality and its warranty would be more or less non-existent, the modifications I have done will have blown away any chance of a warranty claim if there was any. Before I get into too much detail the usual safety warning if you don’t know what you are doing don’t attempt this, there are capacitors on the boards which charge up to high voltages and can remain like this for a long time after power is removed. I dropped the add in pilot arc board on a steel bench and the capacitor rated at 250V made quite a spark and it had been disconnected from the mains for at least 4 weeks. The plasma cutter I bought looked like below, the two things I didn’t like were the impossibly short mains lead with a dodgy plug on the end and the pilot arc connection, I therefore decided to change the torch connector to a Trafimet type one. It is my firm belief that the pilot arc was an addition to the original design, this is backed up by the poor way the pilot arc board is fitted, more on this later. This modification won’t make your plasma cutter perform any better, I just really hated the pilot arc connection I guess that is just me.

Modification 1

If your plasma cutter or cheap welder has a normal 13A plug check the fuse, I found below under the fuse carrier that had been hot melt glued in.

If you have this cut the plug off chuck it away and either stick a standard 13A fused plug or a 16A industrial plug on the end. I was quite impressed that they had managed to solder such a large piece of copper in without melting the plastic plug body. For me the only 16A plug I have feeds the compressor and I needed to plug it into a 32A feed I use on my Mig, wasn’t convinced the internal wiring was up to a 32A supply so fitted this with a 16A type C MCB.

Modification 2

My second modification concerns that pilot arc connection I hated, I purchased a Trafimet Central type connector from Aliexpress, cost me around £23 delivered for both plug and socket if you are looking for one search for “fy0023”. What I got looked like below but also included a springy cable strain relief and disconnect tool this is shown in a picture later.

The existing torch connection looks like this

And once removed like this

The whole front panel can be removed to make it easier by disconnecting the electrical connections, you’ll need to peel off the hot melt glue from the plugs after making a note of where everything goes and undoing 3 screws on the base. The new connector has a larger hole, I opened mine up to 30mm which covered the original anti-rotation lug holes, the new connector also has a single anti-rotation lug and I just added this with a file after drilling out. If I was doing again I would consider moving the new connector up, you will notice from below that the air hose is very close to the PCB connector on the original torch connection. The new connector is longer and the front panel slopes slightly back and interfered with the PCB connector. I only realised this after and got around it by unsoldering the connector from the PCB and soldering the wires directly into the PCB.

There appears to be many pin out variants on the way you connect these Trafimet connectors, from the Trafimet catalogue I decided to use the Trafimet standard pin out as below.

Once fitted the connector looked like below, the switch wires are soldered and heat shrink insulated, the two pilot arc connections from the Trafimet connector has been removed from the red pilot arc terminal and soldered to the two blue components and the thicker wire which goes off to the pilot arc board. There are spare wires on the Trafimet I left disconnected but available for use if needed.

The main plasma connection to the PCB is via an aluminium bracket, I had to manufacture a new one as the dimensions are different and the hole was bigger. The air hose connector is smaller than the original (6mm), I slid a small piece of tube over first to pad it out and tightened the jubilee clip.

The torch connector is show below it has a ¼ BSPP male thread for the main connection and is supplied with an adaptor to M12 female. I think the original plasma connector is M16, I made an adaptor out of the original front panel connector 1/4bsp to M16, I wouldn’t recommend this, and there is plenty of room in the connector for an adapter. The pilot arc and switch connections are via push in pins, I guess you need a specific crimp tool for these which most won’t have, the pins need to remain circular when fitted so I soldered my wires into the pins. The pins just seem to push in and not lock in unless there is a trick to.

To be continued