Darrell Dieringer

New Member

- Messages

- 7

- Location

- USA - Seattle, WA

I've been using my buddy's Dan-Mig 140 Mono. I used it earlier today and it worked fine. Until it stopped making an arc - mid project of course.

I managed to find a number of posts on these forums regarding the Dan-Mig 140 Mono (aka Migatronic 140 Mono). This post (https://www.mig-welding.co.uk/forum/threads/dan-mig-140-mono.98734/) and others it lead me to helped me troubleshoot.

My buddy is the original owner of the machine and I know he has made no modifications to it.

Here's what I've checked:

Here's what happened:

I know enough about electronics to follow a schematic, locate components, and operate a multi meter safely. As far as failed circuit board component diagnosis, I'll need some hand holding.

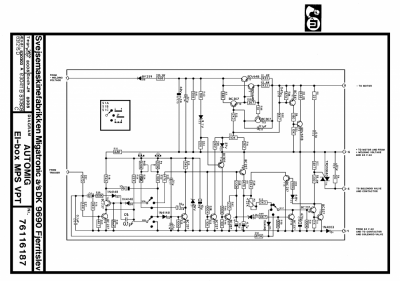

I've identified the triac on the control board appearing as TXD10K40 in the schematic appearing in https://www.mig-welding.co.uk/forum/threads/dan-mig-140-mono.98734/.

I know it's an AC switching component. In a couple of posts on these forums that triac is mentioned in discussion of wire feed problems, though the consensus suggested the wire feed motor is likely a 24V DC motor and that an AC switching component probably doesn't drive it.

I haven't found a definitive reference regarding what that triac does control, so I thought maybe it is causing my "no arc" problem.

On my welder, however, that triac is a "Q2006L4" (well, i'm reasonably sure the last digit is a "4"). With the help of googling "how to test a triac with an ohm meter" and my best amateur skills, it does seem to test fine (though I could be wrong).

I'd appreciate any advice you can offer regarding further troubleshooting. I'm happy to post photos of anything you think might be helpful.

Thank you in advance.

I managed to find a number of posts on these forums regarding the Dan-Mig 140 Mono (aka Migatronic 140 Mono). This post (https://www.mig-welding.co.uk/forum/threads/dan-mig-140-mono.98734/) and others it lead me to helped me troubleshoot.

My buddy is the original owner of the machine and I know he has made no modifications to it.

Here's what I've checked:

- contactor clicks (and plastic button moves) when trigger is pulled

- wire feed works normally when trigger is pulled

- contactor has continuity when energized

- wall plug is wired correctly and wires are properly secured within it

- cord from wall plug is properly connected to terminal block within welder chasis

- welding ground (earth) cord has continuity and is in good condition

- both fuses are correctly sized and have continuity

- both fuse holders have proper continuity when tested from the terminals on their backsides

Here's what happened:

- The machine started welding fine today. It worked for a few welds quite well

- Then, I started getting a weaker arc.

- Then the arc "sputtered".

- Then it failed.

- The "weaker-sputter-fail" timeline was about five minutes of normal intermittent use.

- I hadn't moved the machine (so no sudden impacts or bumps or knocks), nor had I changed any settings.

I know enough about electronics to follow a schematic, locate components, and operate a multi meter safely. As far as failed circuit board component diagnosis, I'll need some hand holding.

I've identified the triac on the control board appearing as TXD10K40 in the schematic appearing in https://www.mig-welding.co.uk/forum/threads/dan-mig-140-mono.98734/.

I know it's an AC switching component. In a couple of posts on these forums that triac is mentioned in discussion of wire feed problems, though the consensus suggested the wire feed motor is likely a 24V DC motor and that an AC switching component probably doesn't drive it.

I haven't found a definitive reference regarding what that triac does control, so I thought maybe it is causing my "no arc" problem.

On my welder, however, that triac is a "Q2006L4" (well, i'm reasonably sure the last digit is a "4"). With the help of googling "how to test a triac with an ohm meter" and my best amateur skills, it does seem to test fine (though I could be wrong).

I'd appreciate any advice you can offer regarding further troubleshooting. I'm happy to post photos of anything you think might be helpful.

Thank you in advance.