daxliniere

Member

- Messages

- 174

- Location

- North London, UK

Hey gang,

I need to true the jaws of my 3-jaw lathe chuck and have been thinking about building a small toolpost grinder. It doesn't need to be the world's most rigid or highest powered since I'm really just making it to avoid buying a new 3-jaw chuck.

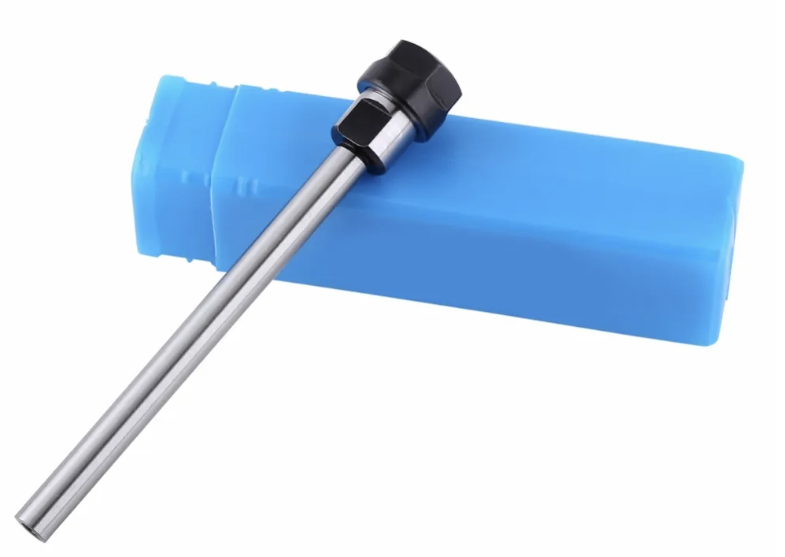

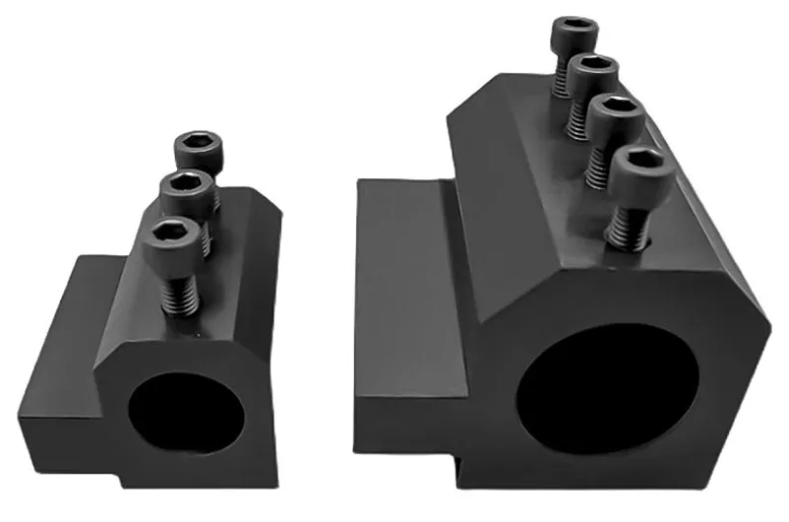

The current plan is to use an ER11 collet holder as the spindle, a pair of needle bearings (8mm ID, 12mm OD, 12mm long), maybe a thrust bearing on each end and an auxiliary boring bar holder or linear bearing block (with linear bearings replaced with needle bearings). I'm unsure of what I'll use to spin it or how I'll couple that motor, but probably a Dremel since it's 36,000 RPM and I own it already.

Anyone got any thoughts on this?

All the best,

Dax.

I need to true the jaws of my 3-jaw lathe chuck and have been thinking about building a small toolpost grinder. It doesn't need to be the world's most rigid or highest powered since I'm really just making it to avoid buying a new 3-jaw chuck.

The current plan is to use an ER11 collet holder as the spindle, a pair of needle bearings (8mm ID, 12mm OD, 12mm long), maybe a thrust bearing on each end and an auxiliary boring bar holder or linear bearing block (with linear bearings replaced with needle bearings). I'm unsure of what I'll use to spin it or how I'll couple that motor, but probably a Dremel since it's 36,000 RPM and I own it already.

Anyone got any thoughts on this?

All the best,

Dax.