Dutch Welder

Member

- Messages

- 402

- Location

- Oss, The Netherlands

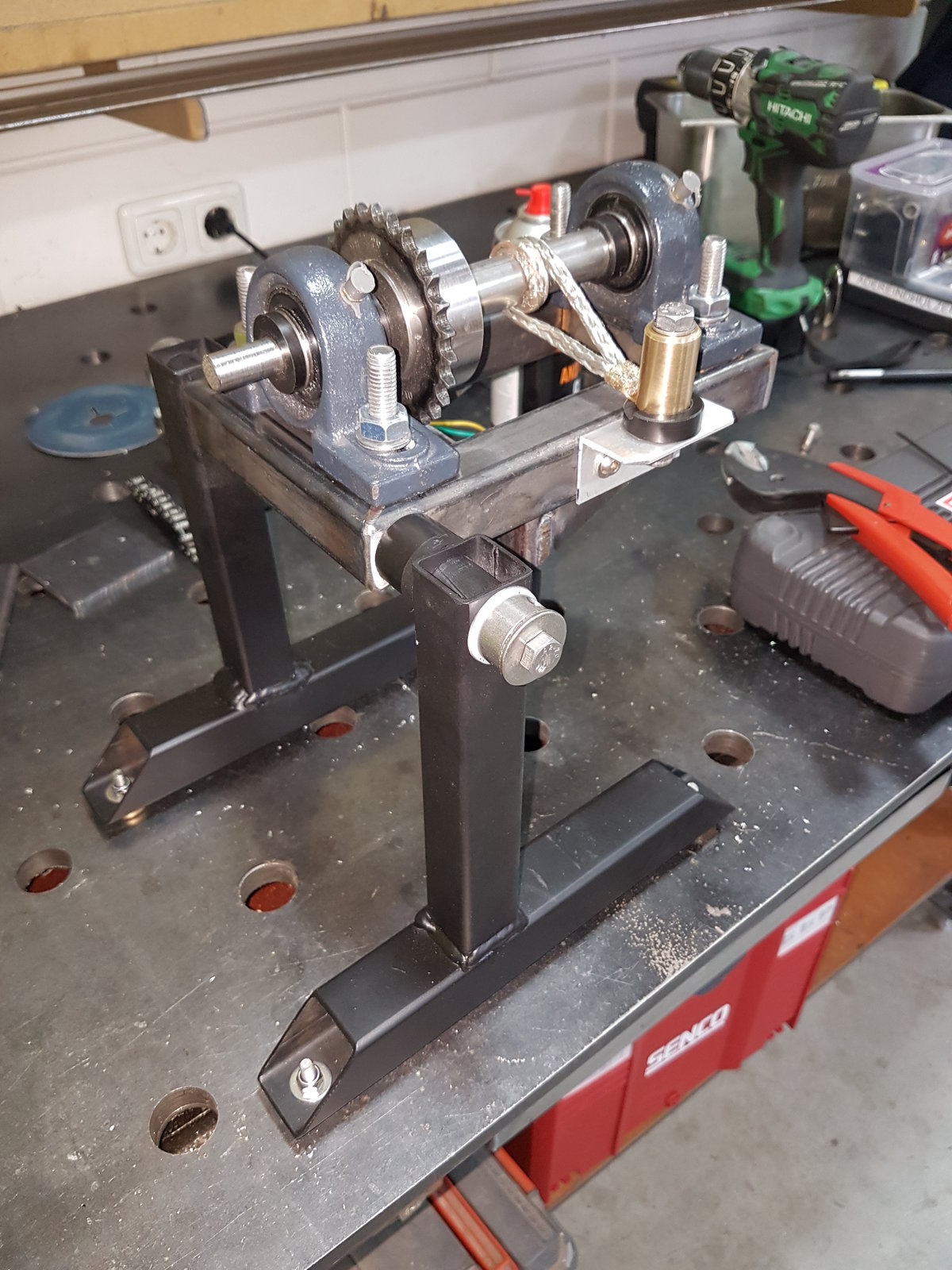

I made a welding manipulator/rotator some time ago,l but it was quite cumbersome and bulky.

It used a 230v 3 phase motor, a 100:1 reduction gearbox and a VFD.

This led to a relatively heavy and bulky rotator

I don't use it much, and if I do it's for small parts like a fitting on a catchtank.

So I wanted a smaller version which can be chucked under the bench easily.

I've found a topic on a US forum where they used a stepper motor and an arduino for speed control.

http://weldingweb.com/showthread.php?669931-Chinese-positioner-Anyone-use-one

I have made some improvements to the original version.

In the original version the arc can possibly travel through the bearings and into the Arduino/Stepper driver/power supply, this was a thing I wanted to avoid, as I've found an Arduino being really prone to outside interference. As an example the test setup would refuse to stop when the stop button was pressed, this turned out to be the CCW rotation wire was running parallel to the stepper driver wires, and the induced energy was enough to trigger the Arduino to rotate CCW

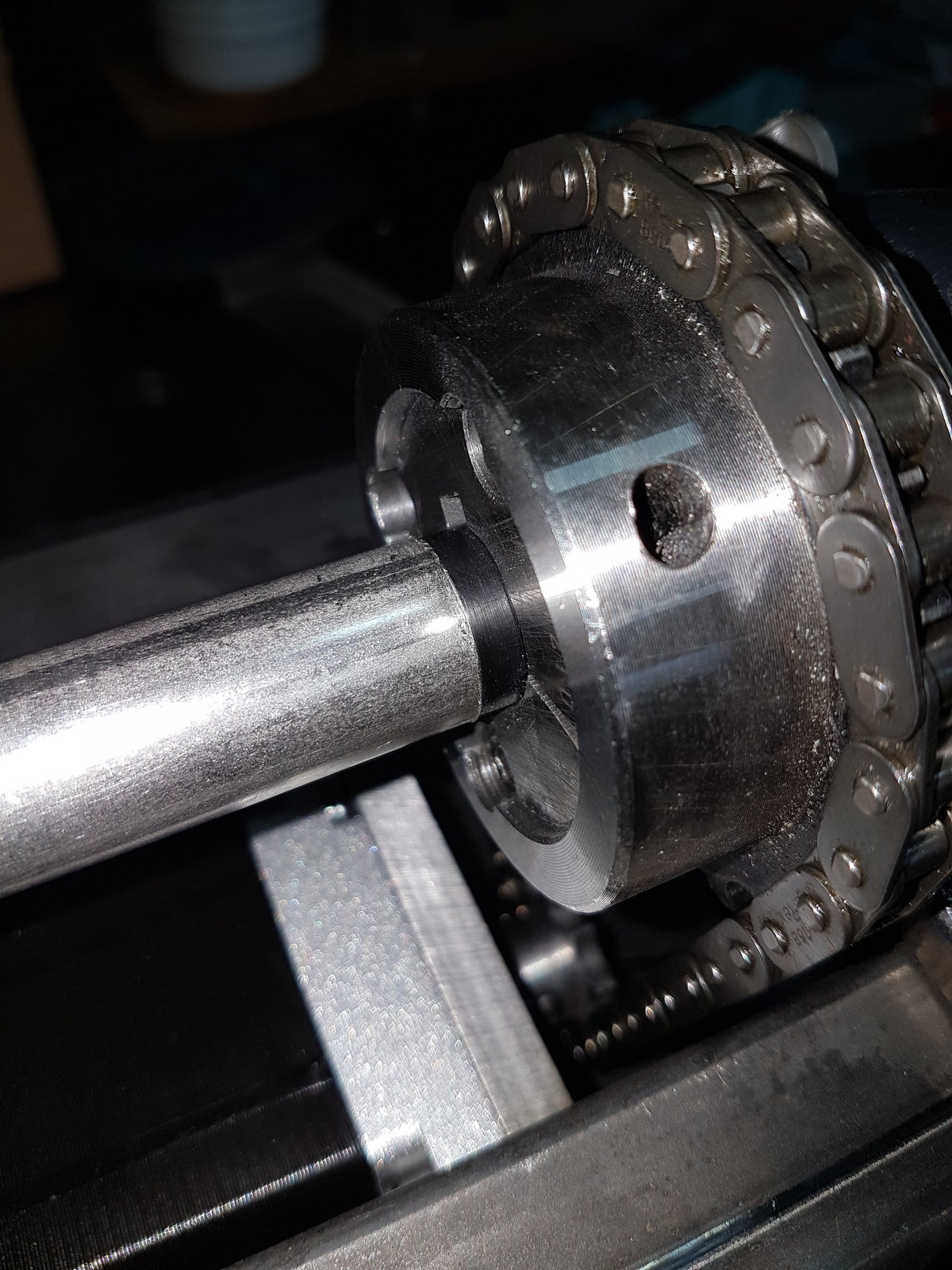

That is why I turned down the steel shaft at the places where the bearings and the sprocket sit, and sleeved it at those locations with a non conducting plastic sleeve, turned down to the original diameter of the steel shaft.This way the arc can not travel through the bearings.

I did the same at the pivot locations, there is a plastic bush inserted there, so again, the ground/arc energy can never reach the Arduino. The black part is hollow, and has a solid shaft running through it.

On the rear side a bush clamps the shaft, I am now working on a solution to stop the shaft from rotating, without it being electrically conducting, and in the front there is going to be a handle (where the bolt is now) If it tighten the handle the unit can be clamped in any postion between vertical and horizontal.

I am probably going to weld a small piece of iron angle to the rear bush, with a plastic spacer between it and the frame, this way the shaft can not rotate. I tried the locking action by holding the rear bush with a vice grip and tightening the front bolt with a spanner, and with some moderate force I can not rotate the frame by putting my weight on it. More then enough clamping force for me.

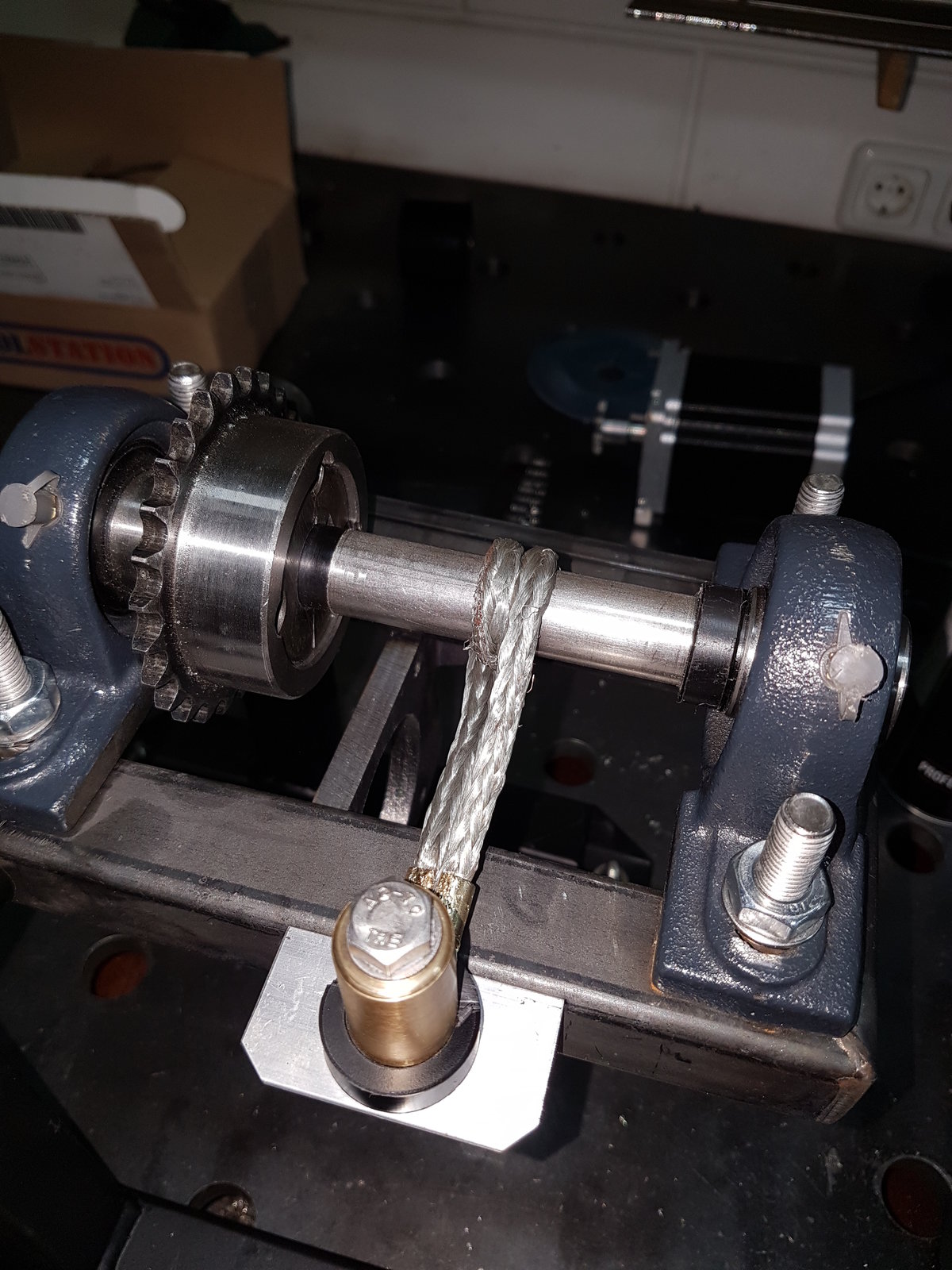

The ground is transfered to the shaft (and the plate or chuck mounted to it via a flexible woven braid and a brass stub, this is connected to the frame mechanically, but is isolated electrically by again using a plastic bush which prevents the bolt or the stub from actually contacting any other metal parts. I will put some heat shrink on here, so that only the loop around the shaft will be exposed.

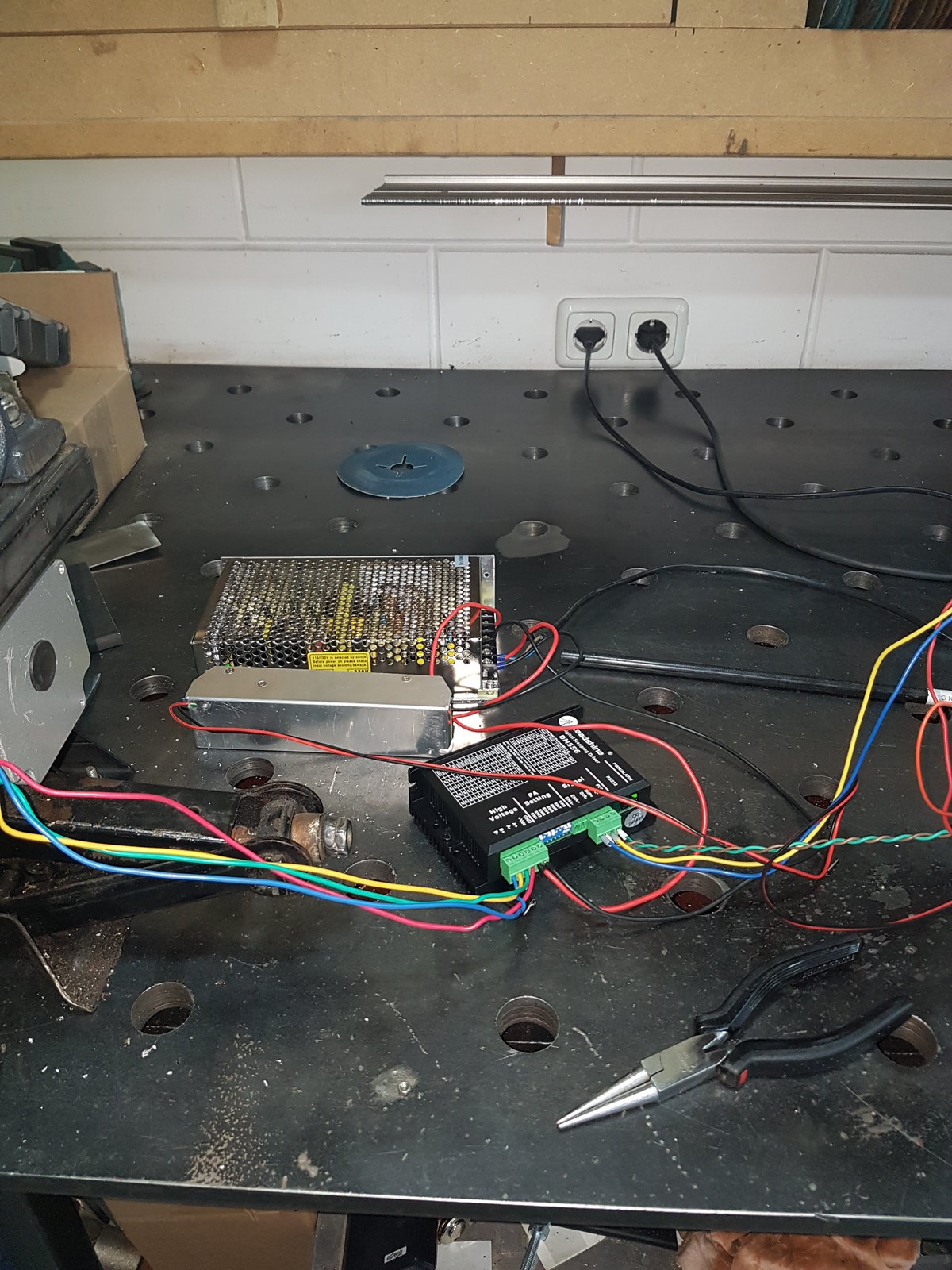

Powersupplies, 26v for the stepper driver, 12v for the Arduino and the stepper driver (6 amp max driving current) I am driving a Nema 34 stepper, the original version uses a smalle less powerfull version, but I had this already.

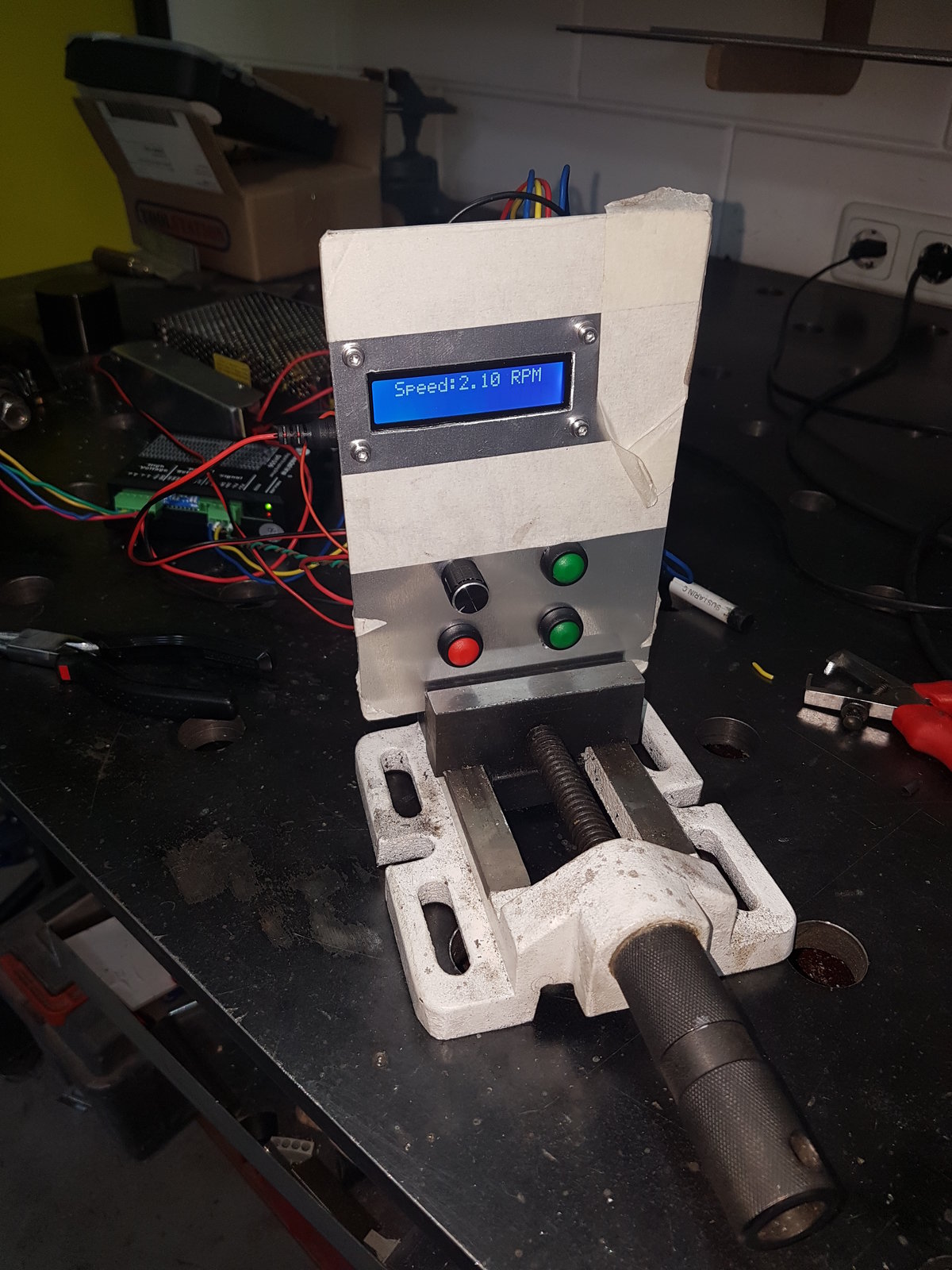

This is the control panel.

Speed can be set from 0.1 to 10 RPM (with the current program, but can be set much higher)

Red button is Stop, the 2 green buttons control CW or CCW rotation.

Only thing missing is a power switch, it's going to be mounted to the right of the LCD screen.

I am expecting the plastic box which houses it all to come in tomorrow, then I can finish it all.

It used a 230v 3 phase motor, a 100:1 reduction gearbox and a VFD.

This led to a relatively heavy and bulky rotator

I don't use it much, and if I do it's for small parts like a fitting on a catchtank.

So I wanted a smaller version which can be chucked under the bench easily.

I've found a topic on a US forum where they used a stepper motor and an arduino for speed control.

http://weldingweb.com/showthread.php?669931-Chinese-positioner-Anyone-use-one

I have made some improvements to the original version.

In the original version the arc can possibly travel through the bearings and into the Arduino/Stepper driver/power supply, this was a thing I wanted to avoid, as I've found an Arduino being really prone to outside interference. As an example the test setup would refuse to stop when the stop button was pressed, this turned out to be the CCW rotation wire was running parallel to the stepper driver wires, and the induced energy was enough to trigger the Arduino to rotate CCW

That is why I turned down the steel shaft at the places where the bearings and the sprocket sit, and sleeved it at those locations with a non conducting plastic sleeve, turned down to the original diameter of the steel shaft.This way the arc can not travel through the bearings.

I did the same at the pivot locations, there is a plastic bush inserted there, so again, the ground/arc energy can never reach the Arduino. The black part is hollow, and has a solid shaft running through it.

On the rear side a bush clamps the shaft, I am now working on a solution to stop the shaft from rotating, without it being electrically conducting, and in the front there is going to be a handle (where the bolt is now) If it tighten the handle the unit can be clamped in any postion between vertical and horizontal.

I am probably going to weld a small piece of iron angle to the rear bush, with a plastic spacer between it and the frame, this way the shaft can not rotate. I tried the locking action by holding the rear bush with a vice grip and tightening the front bolt with a spanner, and with some moderate force I can not rotate the frame by putting my weight on it. More then enough clamping force for me.

The ground is transfered to the shaft (and the plate or chuck mounted to it via a flexible woven braid and a brass stub, this is connected to the frame mechanically, but is isolated electrically by again using a plastic bush which prevents the bolt or the stub from actually contacting any other metal parts. I will put some heat shrink on here, so that only the loop around the shaft will be exposed.

Powersupplies, 26v for the stepper driver, 12v for the Arduino and the stepper driver (6 amp max driving current) I am driving a Nema 34 stepper, the original version uses a smalle less powerfull version, but I had this already.

This is the control panel.

Speed can be set from 0.1 to 10 RPM (with the current program, but can be set much higher)

Red button is Stop, the 2 green buttons control CW or CCW rotation.

Only thing missing is a power switch, it's going to be mounted to the right of the LCD screen.

I am expecting the plastic box which houses it all to come in tomorrow, then I can finish it all.