- Messages

- 6,329

Hi thought id put on some pics of an ongoing overhall job im doing for our local docks, have about 40 of these to do + its sister part the turntable, the drawbars are from the 50ton trailers used to haul timber and steel around the docks..

This is the abused drawbar all the chalked parts are for the scrap bin, eyes are replaced when needed this ones good so its staying. Note the bits of plate on it from the many patch up jobs from the onsite fitters.

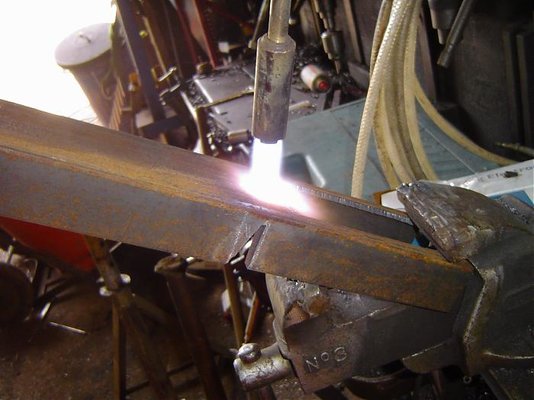

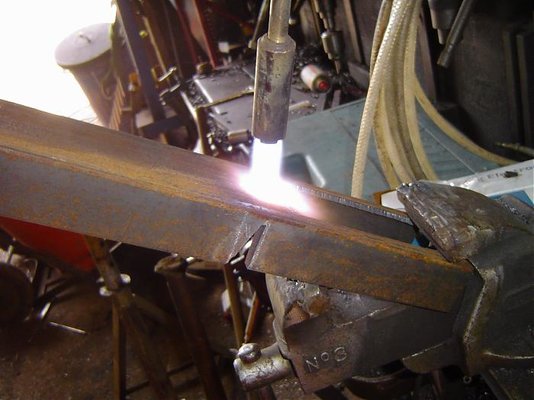

I use 2 bits of 40mm solid bar for the back plate, I always arc big material from that school im afraid, note the nice peal from the slag good sign you have your heat and speed right, the T welds on on this back part will have a 4mm root followed by 2* 5mm passes.

2 new side rails are made, these are shaped with the plasma the cut out is to weld the eye in place, they are given a bit of heat then bent.

Building a good jig for multiple work makes life much more easy, the parts are simply banged into position and clamped, no more use of a tape or square is needed, all the remaining welds are then done with the mig.

Finished, note the added 1/2 inch centre brace, there is also a number welded on each one, a tab and a costing is kept for all kit on the docks.

Cheers for looking il dig out some more projects if there of intrest.

This is the abused drawbar all the chalked parts are for the scrap bin, eyes are replaced when needed this ones good so its staying. Note the bits of plate on it from the many patch up jobs from the onsite fitters.

I use 2 bits of 40mm solid bar for the back plate, I always arc big material from that school im afraid, note the nice peal from the slag good sign you have your heat and speed right, the T welds on on this back part will have a 4mm root followed by 2* 5mm passes.

2 new side rails are made, these are shaped with the plasma the cut out is to weld the eye in place, they are given a bit of heat then bent.

Building a good jig for multiple work makes life much more easy, the parts are simply banged into position and clamped, no more use of a tape or square is needed, all the remaining welds are then done with the mig.

Finished, note the added 1/2 inch centre brace, there is also a number welded on each one, a tab and a costing is kept for all kit on the docks.

Cheers for looking il dig out some more projects if there of intrest.