rtbcomp

Moderator

- Messages

- 18,549

- Location

- Sheffield UK

I've just acquired two of these, this is about getting the first one, nearest the camera, up and running.

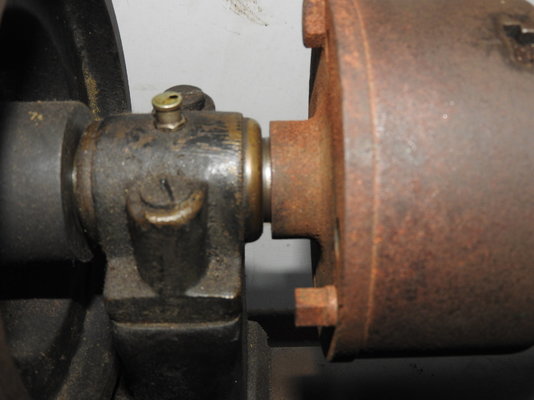

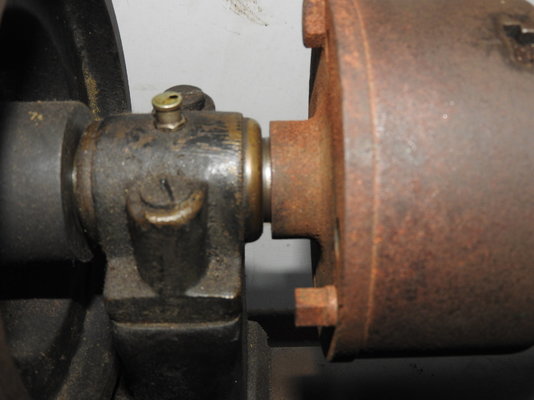

The first thing I noticed was that when you screwed a chuck on it jammed the spindle. This was because the spindle was too far to the left due to some washers which were placed between the bearing and the locating collar. These were removed and the end-float taken up by moving the pulley to the left. There is now some clearance between the chuck thread and the bearing.

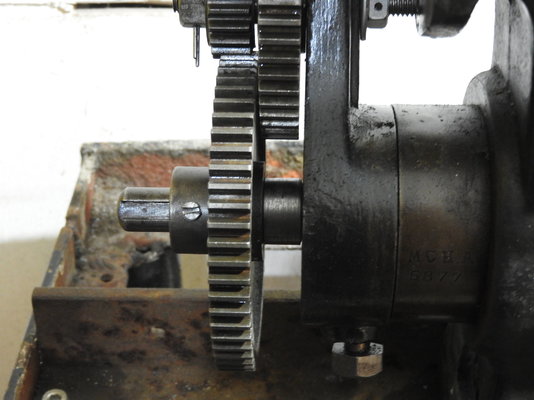

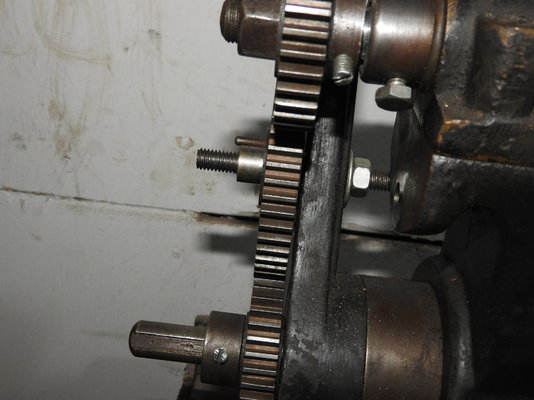

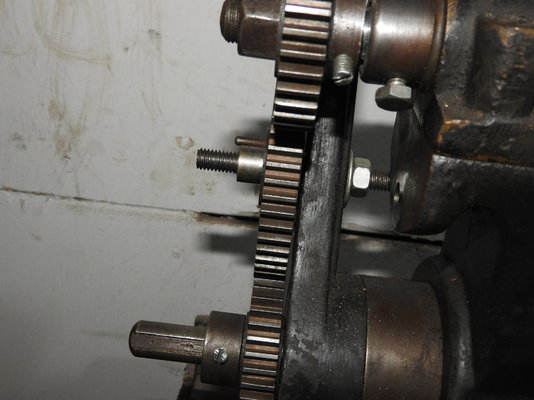

Sorting this also allowed the change wheels to line up properly.

There was no means of locking the final change wheel to the leadscrew, so a spare spacer was drilled and tapped 1/4 BSW and a grub screw made to secure it; so now the spindle turns freely and drives the saddle.

The first thing I noticed was that when you screwed a chuck on it jammed the spindle. This was because the spindle was too far to the left due to some washers which were placed between the bearing and the locating collar. These were removed and the end-float taken up by moving the pulley to the left. There is now some clearance between the chuck thread and the bearing.

Sorting this also allowed the change wheels to line up properly.

There was no means of locking the final change wheel to the leadscrew, so a spare spacer was drilled and tapped 1/4 BSW and a grub screw made to secure it; so now the spindle turns freely and drives the saddle.

- you planning a motor?

- you planning a motor?