gasket999

getting there...

- Messages

- 355

- Location

- Manchester, UK

Hi folks.

ever since the pressurised blast pots became cheaply available there has been a heap of posts about using them, improving them or even copying them to a higher standard.

This forum is full of tips and suggestions for improvements - some work and some haven't stood the test of time.

Stormin, RTBcomp and Brightspark have all provided a great deal of fantastic info as does the section on the home page.

Given that not many people (myself included) are sufficiently proficient in welding to build their own tank from a gas bottle, I wonder if we could combine the available info to produce a "recipe" for a reliable, reasonably performing setup for the DIY user - either freestanding or in a cabinet.

From my searches I thought I'd start off with the known-basics. All of this comes from the forum rather than my own experience:

I obviously have a vested interest here. I've just got a second hand 4hp clarke compressor (18CFM) while I save up for the tandem pump one. I restore cars and also have a job I have to do which will justify me building a basic blasting setup (7 cast iron radiators that have to be blasted and painted - getting this done commercially including two van rentals easily justifies getting a small kit, if it can work. Especially given I'm happy to do these one at a time as I decorate the house).

So if we start on the assumption that we buy the 20 gallon kit and immediately bin/return/forgo or sell off everything except the tank and replace everything else with better components (valves, hoses, nozzles, visor) - what do we recommend?

Given a parts list I'll try and do the donkey work by posting links and the best prices to make it easier for others to buy the recipe.

Personally, I'd say a budget of around £200 is reasonable for the hobbyist - £70 buys the tank, say you flog off the unused, unwanted spares for £15 - that gives a budget of £145 to improve the setup using better quality or better designed components.

Does anyone have any suggestions? Valves? Hoses? Regulator? Dryer/drain?

Machine mart parts are a favourite given the VAT-free events.

ever since the pressurised blast pots became cheaply available there has been a heap of posts about using them, improving them or even copying them to a higher standard.

This forum is full of tips and suggestions for improvements - some work and some haven't stood the test of time.

Stormin, RTBcomp and Brightspark have all provided a great deal of fantastic info as does the section on the home page.

Given that not many people (myself included) are sufficiently proficient in welding to build their own tank from a gas bottle, I wonder if we could combine the available info to produce a "recipe" for a reliable, reasonably performing setup for the DIY user - either freestanding or in a cabinet.

From my searches I thought I'd start off with the known-basics. All of this comes from the forum rather than my own experience:

- A 3hp compressor is a minimum. Given this is going to be running flat-out, a belt drive is preferable. Larger 4hp or tandem setups are preferred.

- The 20 gallon blaster is only slightly more than the 10 gallon one and saves refilling as often.

- The ceramic nozzles are not suited to extended use, neither is the dead-man's handle. The solution is to buy a tungsten nozzle from Ace, chop off the old handle and fit this in the tube with a jubilee clip.

- A 3mm nozzle is the biggest you are likely to be able to use on a 'garage' (3-4HP) compressor.

- The more expensive versions from Eastwood and Clarke are likely made to similar standards as the cheap eBay ones and probably aren't worth three or four times the cost (bit of an assumption on my part here)

- The media has to be dry to avoid blockages.

I obviously have a vested interest here. I've just got a second hand 4hp clarke compressor (18CFM) while I save up for the tandem pump one. I restore cars and also have a job I have to do which will justify me building a basic blasting setup (7 cast iron radiators that have to be blasted and painted - getting this done commercially including two van rentals easily justifies getting a small kit, if it can work. Especially given I'm happy to do these one at a time as I decorate the house).

So if we start on the assumption that we buy the 20 gallon kit and immediately bin/return/forgo or sell off everything except the tank and replace everything else with better components (valves, hoses, nozzles, visor) - what do we recommend?

Given a parts list I'll try and do the donkey work by posting links and the best prices to make it easier for others to buy the recipe.

Personally, I'd say a budget of around £200 is reasonable for the hobbyist - £70 buys the tank, say you flog off the unused, unwanted spares for £15 - that gives a budget of £145 to improve the setup using better quality or better designed components.

Does anyone have any suggestions? Valves? Hoses? Regulator? Dryer/drain?

Machine mart parts are a favourite given the VAT-free events.

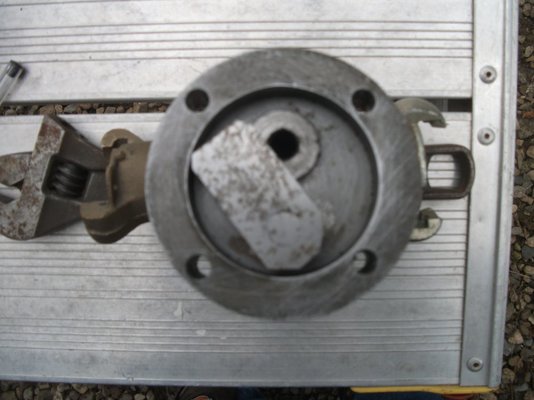

pretty easy to make but takes about 4 hours to make them

pretty easy to make but takes about 4 hours to make them

they work real well on 1.5mm grit .down to kiln dried sand. with the regulating plate sitting proud of the outlet any iregular media doesnt block the orifice it drops to one side and the flow carries on. they just need cleaning out now and again

they work real well on 1.5mm grit .down to kiln dried sand. with the regulating plate sitting proud of the outlet any iregular media doesnt block the orifice it drops to one side and the flow carries on. they just need cleaning out now and again