Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,951

- Location

- NE London - UK

I came by a new spin indexer a few weeks back with a selection of 5C collets. All well and good, but fairly restricted in the range. Whilst looking around for a matching tailstock, I came upon the Stephenson 5C Indexer which also takes ER32 collets. This set me thinking

The Stephenson uses an oversized collet closer nut and the threaded portion of the indexer spindle, which is usually machined parallel, has the thread right to the end. I believe it then uses a special sleeve to fit inside the spindle.

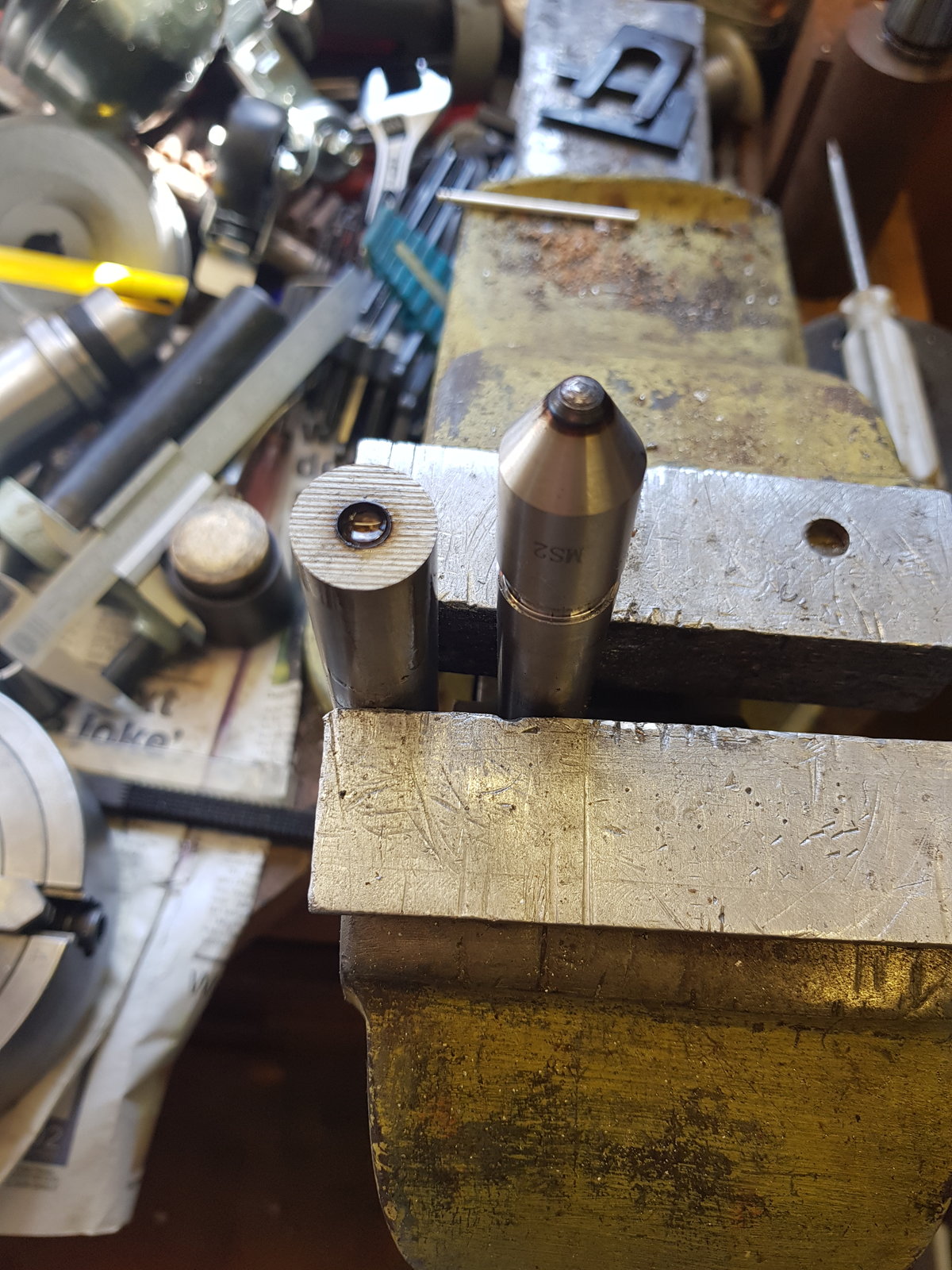

After several mental iterations of how I was going to achieve a modification so that mine was AC/DC, so to speak , I picked up an ER adaptor that I made two or three years ago, to fit the quill on my Progress 2 to allow me to mill. It worked but was not entirely successful since there was too much run out. It was relegated to a space on the bench, where it got buried. It surfaced during a tidy up and seemed to be the obvious starting point since it saved me having to machine the taper and thread cut again.

, I picked up an ER adaptor that I made two or three years ago, to fit the quill on my Progress 2 to allow me to mill. It worked but was not entirely successful since there was too much run out. It was relegated to a space on the bench, where it got buried. It surfaced during a tidy up and seemed to be the obvious starting point since it saved me having to machine the taper and thread cut again.

I did a Millyard on it. Think about it, visualise how it's going to look, and do it. No need for anything other than a few measurements to ensure everything was more or less feasible. Drawings are for amateurs.

First off I set the compound for 10°

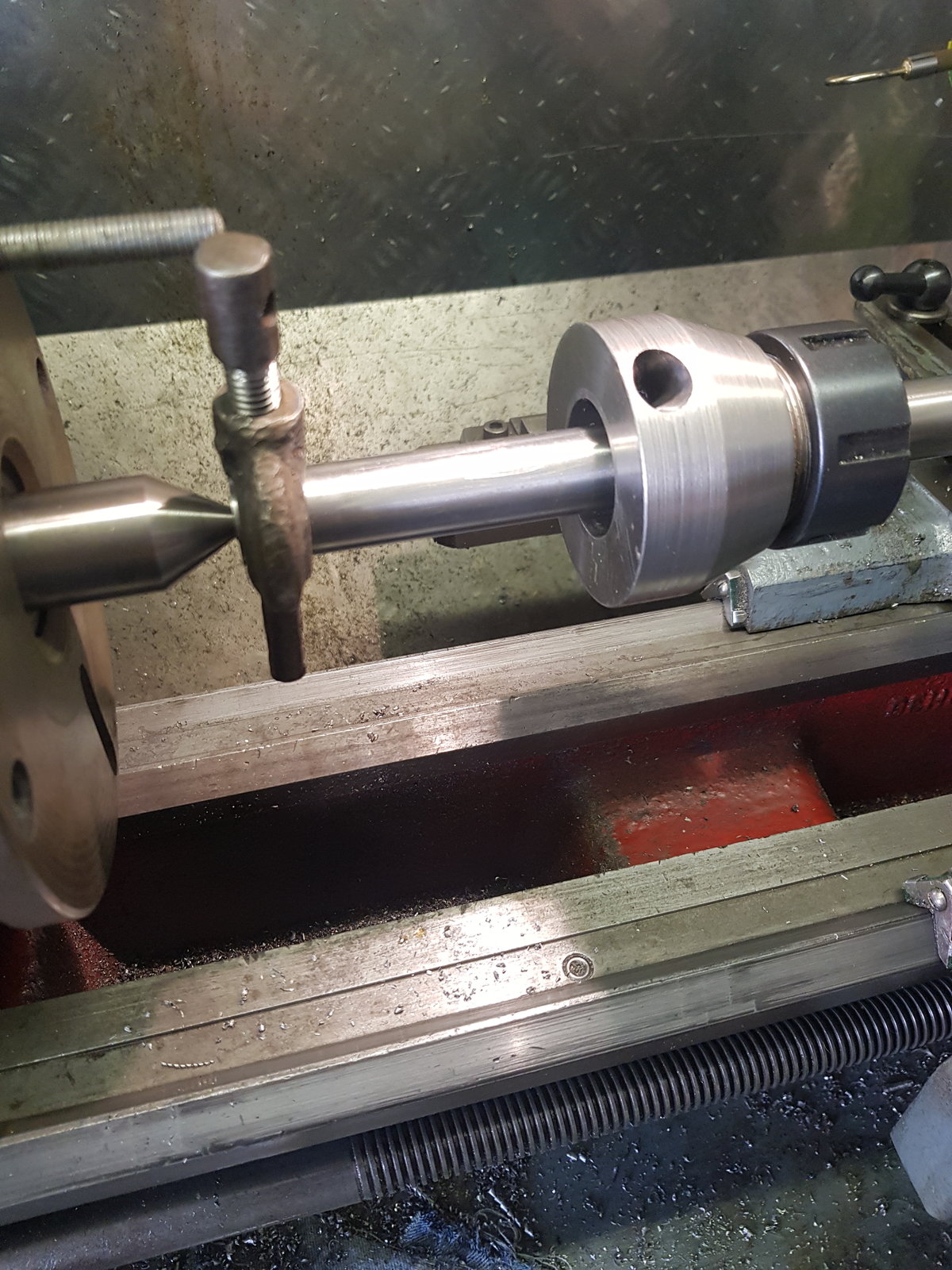

I then chucked it on the lathe between centres, mounted on a piece of 20mm silver steel, and set to.

Christ knows what the steel is, but it was damned tough (like every piece of odd stock that I've collected)

After quite some time with stops for coffee, thought, and the odd measurement, it became this

Having a root around in the scrap box I turned up a piece of 1" gas nipple. Just right methinks

It's a little light in places but I thought there'd be enough steel for it to work. I rough turned the OD and bored the ID to size for the spigot on the rear of the chuck head. Once again I got the silver soldering kit out

I now need to buy some more as there's been a run on it at No.40

By midnight I'd glued it together

Time for bed I think, except I was too awake and thought I'd just do a little more, since everything was going so well

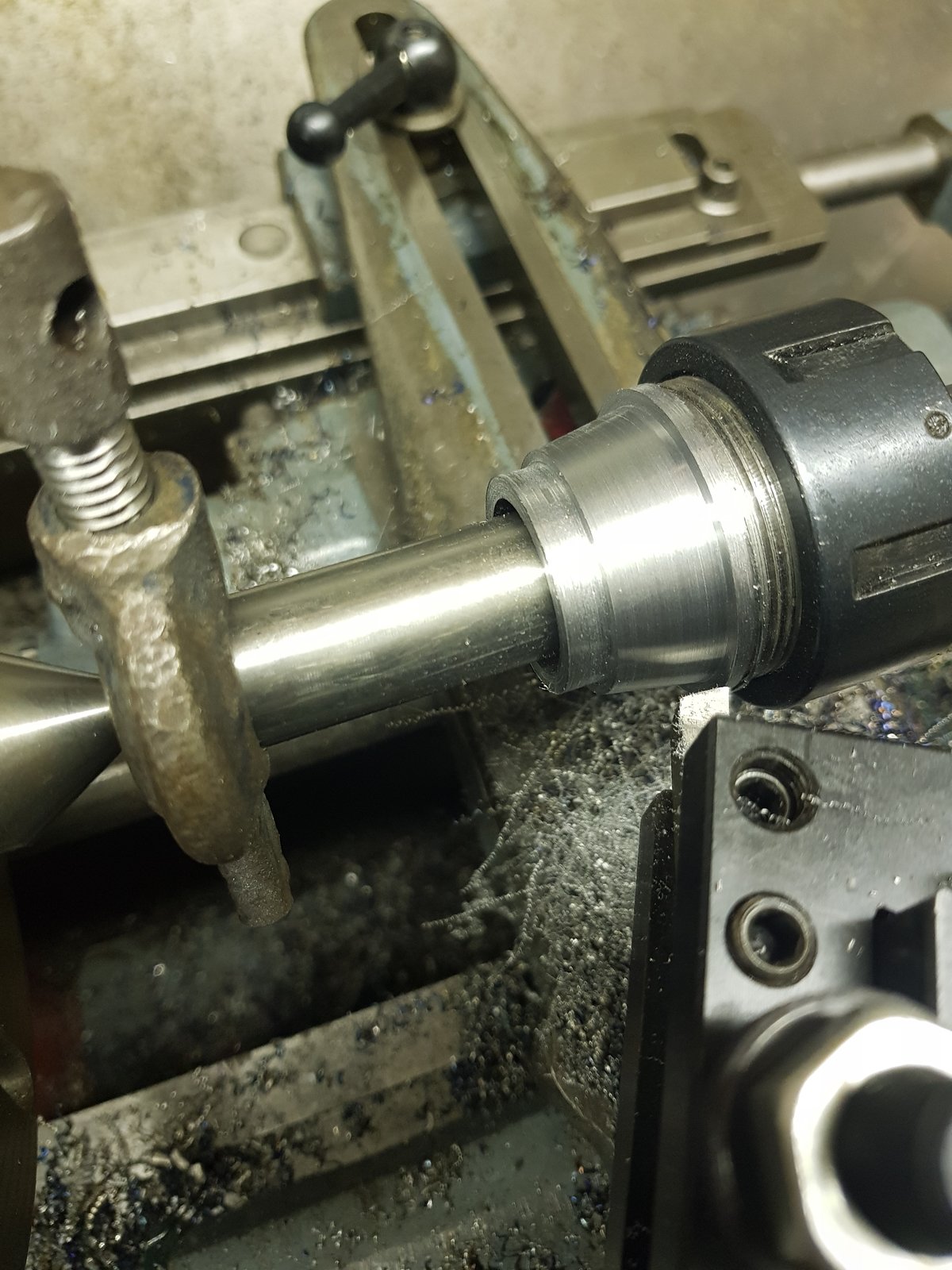

I'd spent some time pontificating (don't worry, it's legal now) as to how I was going to hold a gnarly old piece of gas barrel and centre it so that I could turn the rest of the diameter to size. I hit upon the wonderful idea of having a centre in the spindle together with the four-jaw and a collet in the ER chuck so that I could centre the chuck end up and hopefully get some sort of accuracy. I spent a long time fiddling, tweaking, hitting with a lead hammer, but I couldn't get it running truer than about 3 thou. It was late, so that would have to do, I wanted to do some turning now. Five minutes into this I started getting some serious chatter which was strange since it was running between centres. I then noticed that the silver steel bar was warm. No, it was hot. Actually, the nearer you got to the tail stock the hotter it got, because the apprentice had forgotten to lubricate the DEAD centre (that I'd spent some time on in the afternoon adapting it so that it would come out of the tail stock quill more easily).

It did a pretty fair impression of friction welding

In trying to remove the silver steel from the ER chuck, I found it almost impossible to undo the closer nut, it seemed to have picked up quite badly, to the point where even with it on the bench it was all I could do to get a couple of turns out of it, but at least it was enough to release the bar.

It was at this point, with the potential of having knackered the centre and completely buggering up the thread on the chuck body and nut that I thought "Now it's time for bed." Pausing only to liberally douse everything in WD40, I retired for the night, a not very happy bunny.

The Stephenson uses an oversized collet closer nut and the threaded portion of the indexer spindle, which is usually machined parallel, has the thread right to the end. I believe it then uses a special sleeve to fit inside the spindle.

After several mental iterations of how I was going to achieve a modification so that mine was AC/DC, so to speak

, I picked up an ER adaptor that I made two or three years ago, to fit the quill on my Progress 2 to allow me to mill. It worked but was not entirely successful since there was too much run out. It was relegated to a space on the bench, where it got buried. It surfaced during a tidy up and seemed to be the obvious starting point since it saved me having to machine the taper and thread cut again.

, I picked up an ER adaptor that I made two or three years ago, to fit the quill on my Progress 2 to allow me to mill. It worked but was not entirely successful since there was too much run out. It was relegated to a space on the bench, where it got buried. It surfaced during a tidy up and seemed to be the obvious starting point since it saved me having to machine the taper and thread cut again. I did a Millyard on it. Think about it, visualise how it's going to look, and do it. No need for anything other than a few measurements to ensure everything was more or less feasible. Drawings are for amateurs.

First off I set the compound for 10°

I then chucked it on the lathe between centres, mounted on a piece of 20mm silver steel, and set to.

Christ knows what the steel is, but it was damned tough (like every piece of odd stock that I've collected)

After quite some time with stops for coffee, thought, and the odd measurement, it became this

Having a root around in the scrap box I turned up a piece of 1" gas nipple. Just right methinks

It's a little light in places but I thought there'd be enough steel for it to work. I rough turned the OD and bored the ID to size for the spigot on the rear of the chuck head. Once again I got the silver soldering kit out

I now need to buy some more as there's been a run on it at No.40

By midnight I'd glued it together

Time for bed I think, except I was too awake and thought I'd just do a little more, since everything was going so well

I'd spent some time pontificating (don't worry, it's legal now) as to how I was going to hold a gnarly old piece of gas barrel and centre it so that I could turn the rest of the diameter to size. I hit upon the wonderful idea of having a centre in the spindle together with the four-jaw and a collet in the ER chuck so that I could centre the chuck end up and hopefully get some sort of accuracy. I spent a long time fiddling, tweaking, hitting with a lead hammer, but I couldn't get it running truer than about 3 thou. It was late, so that would have to do, I wanted to do some turning now. Five minutes into this I started getting some serious chatter which was strange since it was running between centres. I then noticed that the silver steel bar was warm. No, it was hot. Actually, the nearer you got to the tail stock the hotter it got, because the apprentice had forgotten to lubricate the DEAD centre (that I'd spent some time on in the afternoon adapting it so that it would come out of the tail stock quill more easily).

It did a pretty fair impression of friction welding

In trying to remove the silver steel from the ER chuck, I found it almost impossible to undo the closer nut, it seemed to have picked up quite badly, to the point where even with it on the bench it was all I could do to get a couple of turns out of it, but at least it was enough to release the bar.

It was at this point, with the potential of having knackered the centre and completely buggering up the thread on the chuck body and nut that I thought "Now it's time for bed." Pausing only to liberally douse everything in WD40, I retired for the night, a not very happy bunny.

But it was sticky in a couple of places. A clean of both threads with a chaser and thread file soon had that sorted. The Centre, what can I say, a job for another day. Find a new centre, shorten the bar, becaus ethat wasn't helping things and drill new centre holes. Realise that the centre drill that you're using is short and doesn't allow the centre to locate properly

But it was sticky in a couple of places. A clean of both threads with a chaser and thread file soon had that sorted. The Centre, what can I say, a job for another day. Find a new centre, shorten the bar, becaus ethat wasn't helping things and drill new centre holes. Realise that the centre drill that you're using is short and doesn't allow the centre to locate properly