oceanobsession

Member

- Messages

- 321

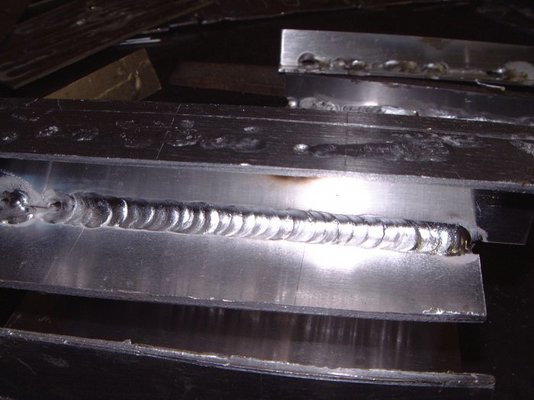

After many hours things seem to be getting a little better. you try that many different things that you dont know what has worked and what hasent. but

ive produced a few exceptable fillet welds. i was not holding to tungstone

close enough. also not enough power. also the right angle with the torch helps to melt just infront of you. where i was going wrong before was melting

both surfaces then dab in the rod but not moving the puddle forward dab in the rod again and so on looks great but when you look after its a mess to much filler i think another problem is the aluminium im welding is 2mm and it

is a fine line between moving the puddle forward and going through see what

you think folks

ocean

ive produced a few exceptable fillet welds. i was not holding to tungstone

close enough. also not enough power. also the right angle with the torch helps to melt just infront of you. where i was going wrong before was melting

both surfaces then dab in the rod but not moving the puddle forward dab in the rod again and so on looks great but when you look after its a mess to much filler i think another problem is the aluminium im welding is 2mm and it

is a fine line between moving the puddle forward and going through see what

you think folks

ocean

on that one Woz. I just cant get my head around the perspective in the photo.

on that one Woz. I just cant get my head around the perspective in the photo. !

!