FergalFarty

Member

- Messages

- 203

- Location

- Bristol

Last night at my evening course I had my first ever go at vertical fillets. The instructor said you always TIG uphill, whereas MIG can be up or down depending on material thickness. Is there any situation where you would TIG downhill?

Anyway here's some photos of my welds. All 5mm mild steel on a massive Lincoln Squarewave 355, WP26 torch, 2.5mm blue tungsten (I think). Please let me know if you think my diagnosis of the weld problems is correct.

Thanks

Fergal

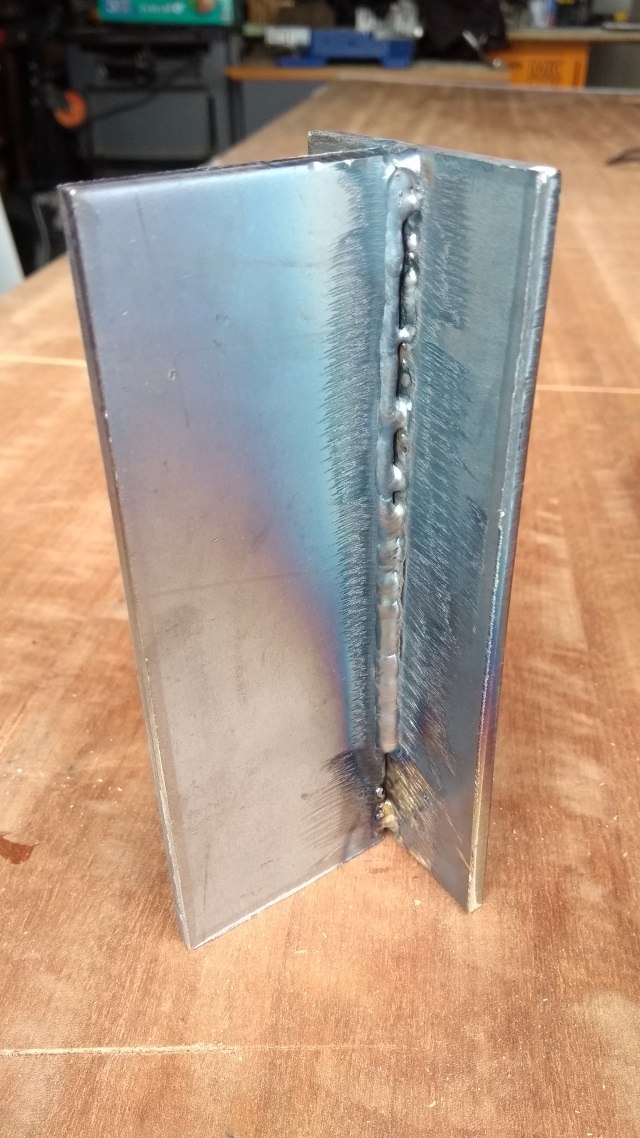

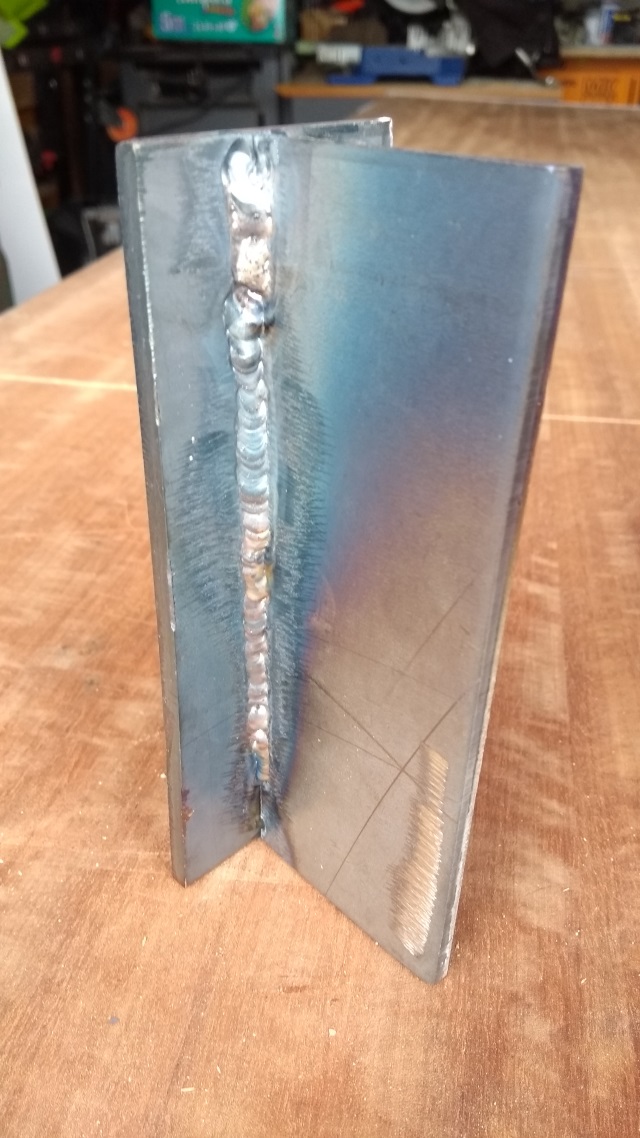

1st attempt 120A I think. Too cold.

2nd attempt 130A, still too cold.

3rd attempt 140A maybe? started off ok, I think I let the arc get too long on the second half.

4th try 160A and a bit more stickout. Much better!

Anyway here's some photos of my welds. All 5mm mild steel on a massive Lincoln Squarewave 355, WP26 torch, 2.5mm blue tungsten (I think). Please let me know if you think my diagnosis of the weld problems is correct.

Thanks

Fergal

1st attempt 120A I think. Too cold.

2nd attempt 130A, still too cold.

3rd attempt 140A maybe? started off ok, I think I let the arc get too long on the second half.

4th try 160A and a bit more stickout. Much better!