ChrisBenoy

New Member

- Messages

- 4

Hi all, been reading this forum for a while and have read a lot, just had my first attempts at welding some metal together, would be nice to get some honest opinions on what i'm doing wrong/any setup changes I might need to do.

Have been working on classic cars for a few years so it has always seemed like a good skill to have. I suspect almost all the welding i'll be doing once I get good enough will be on thin bodywork (0.8-1mm steel) so this is what I have started to learn with.

I realise that its probably a fair bit easier to learn on thicker metal but I thought i'd give it a go.

The equipment (which actually all belongs to my dad) is a SIP Migmate 105 turbo using 0.6mm wire and an argon/co2 mix (couldnt tell you what percentage, i'm guessing something fairly standard) at 10 LPM (in a garage) I gave it a service the other day as it hasnt been used for many years so it has a new tip, shroud and liner (sadly only a plastic one so far). I am also using an auto darkening helmet (great piece of kit). I realise that this isn't the finest welder in the world but it should be ok on thin metal and it seems to be working.

I started off using the lowest power setting (1 of 6) and about medium wire speed, this would work but the penetration was a bit intermittent with too much weld building up on top, I then tried 2 of 6 and this worked much more nicely.

I haven't taken any pictures of my welds on a flat piece of steel, it seems like so long ago that I did them (3/4 hours?) all the pics are of my attempts to butt weld using the thin metal technique.

This one started nicely but I ended up making a hash of it due to the wire feed not running very nicely, I loosened a few things off inside the welder and that seems to have fixed it. Too late for this weld though.

=======================================================

=======================================================

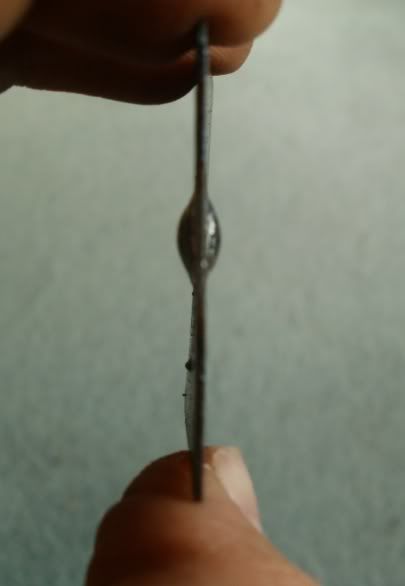

This one looked fairly neat but didn't penetrate very far. After this was the point when I turned up the power on the welder.

=======================================================

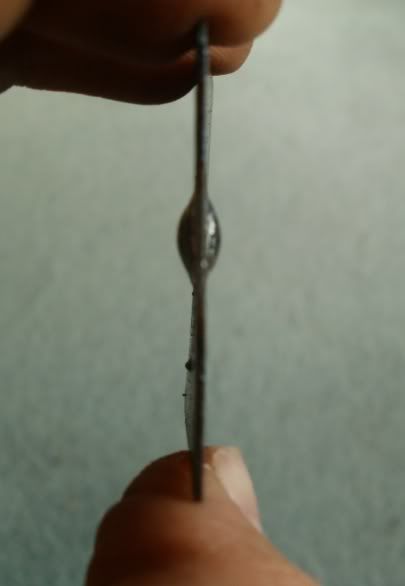

With the power up it seemed to weld better. Not exactly neat and tidy but an improvement?

=======================================================

I then decided to do another double sided one.

=======================================================

This was the last one I did, I finally realised that I wasn't overlapping the stiches as much as I needed to to get a good finish. This was only a quick run but it worked better than most the rest

=======================================================

As you can see from the photos these are just a small selection of the welds, I had cleaned up an offcut of a car panel and just cut that up and welded random bits that lined up together. I'd like to hear everyones opinion on how I can improve.

Thanks,

Chris

p.s sorry for the long post.

Have been working on classic cars for a few years so it has always seemed like a good skill to have. I suspect almost all the welding i'll be doing once I get good enough will be on thin bodywork (0.8-1mm steel) so this is what I have started to learn with.

I realise that its probably a fair bit easier to learn on thicker metal but I thought i'd give it a go.

The equipment (which actually all belongs to my dad) is a SIP Migmate 105 turbo using 0.6mm wire and an argon/co2 mix (couldnt tell you what percentage, i'm guessing something fairly standard) at 10 LPM (in a garage) I gave it a service the other day as it hasnt been used for many years so it has a new tip, shroud and liner (sadly only a plastic one so far). I am also using an auto darkening helmet (great piece of kit). I realise that this isn't the finest welder in the world but it should be ok on thin metal and it seems to be working.

I started off using the lowest power setting (1 of 6) and about medium wire speed, this would work but the penetration was a bit intermittent with too much weld building up on top, I then tried 2 of 6 and this worked much more nicely.

I haven't taken any pictures of my welds on a flat piece of steel, it seems like so long ago that I did them (3/4 hours?) all the pics are of my attempts to butt weld using the thin metal technique.

This one started nicely but I ended up making a hash of it due to the wire feed not running very nicely, I loosened a few things off inside the welder and that seems to have fixed it. Too late for this weld though.

=======================================================

=======================================================

This one looked fairly neat but didn't penetrate very far. After this was the point when I turned up the power on the welder.

=======================================================

With the power up it seemed to weld better. Not exactly neat and tidy but an improvement?

=======================================================

I then decided to do another double sided one.

=======================================================

This was the last one I did, I finally realised that I wasn't overlapping the stiches as much as I needed to to get a good finish. This was only a quick run but it worked better than most the rest

=======================================================

As you can see from the photos these are just a small selection of the welds, I had cleaned up an offcut of a car panel and just cut that up and welded random bits that lined up together. I'd like to hear everyones opinion on how I can improve.

Thanks,

Chris

p.s sorry for the long post.

....if your bodywork man is approachable ,try and spend a day or two with him,offer to come and make tea

....if your bodywork man is approachable ,try and spend a day or two with him,offer to come and make tea  .....you will pick up tips on making patches,distortion,finishing etc ,will speed up your learning considerably ....if the fella is retireing i expect he would be happy for the help.....just a thought

.....you will pick up tips on making patches,distortion,finishing etc ,will speed up your learning considerably ....if the fella is retireing i expect he would be happy for the help.....just a thought