Not right good at taking pictures while doing stuff but think there are enough here to constitute a build thread.

My 10mm blowtorch whilst good wasn't getting a big enough area of steel hot enough so needed to make something a little bigger.

Had a look round the web and youtube and opted for an idea off youtube, mainly because I had some scrap pipe and scaff tube that seemed to fit together quite well.

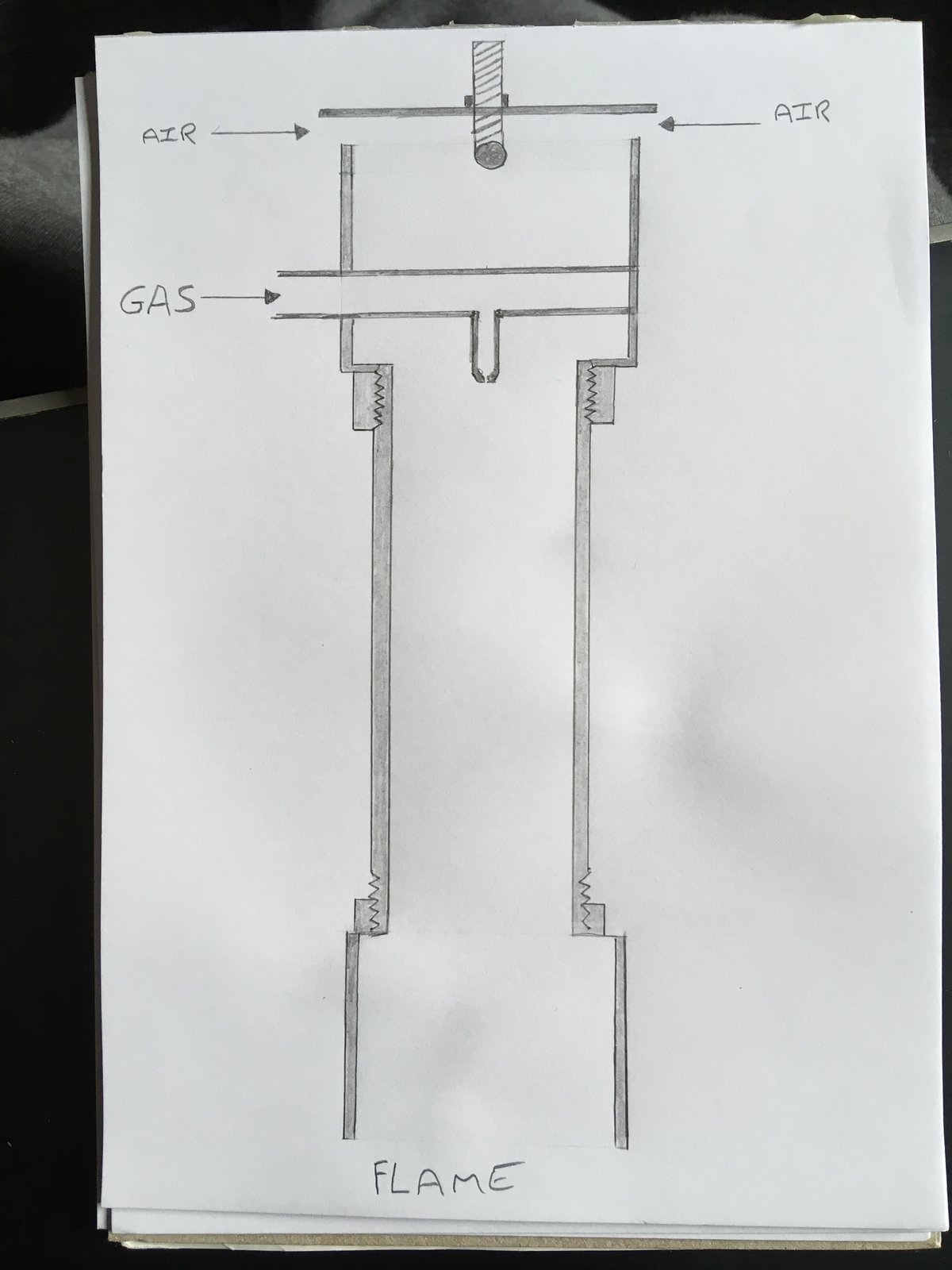

I've drawn this diagram to illustrate the basic principle.

The pipe is something like 1 1/2" diameter I think and this piece was threaded both ends so made an ideal choice. Cut some scaff tube for both ends and cut down a threaded coupler to create a nut for one end as I only had the one nut.

Welded the coupler to one scaff tube and the nut I had to the other.

Then needed to make a central thread to screw on the adjustable choke. An M8 bolt to some round bar would suffice for this.

Needed to create some round cutouts in the top scaff tube piece to allow the choke to sit flat onto the tube when fully screwed down, out with the file and cut a couple of cutouts.

welded into position

The basis of the gas jet is a mig tip screwed into a pipe. I had some 12mm OD steel tube so cut a couple of inches of that and drilled an tapped an M6 threaded hole. Needed some way to fit the 15mm gas ball valve to this pipe so brazed on some 15mm copper pipe, the 12mm steel pipe fitted nicely inside the 15mm copper pipe.

The tube welded into the scaff tube head with the mig tip screwed in place.

all screwed together

with the valve on needed a way to fit the 8mm ID hose to the 15mm pipe so drilled down the centre of an M8 bolt and cut off the head. A 15 to 10mm reducer and an inch or so of 10mm pipe got me down to an ID that the drilled bolt could fit into and brazed it into position. Ran some of the braze into the threads to stop gas leaking down the threads. Hose fits on well with a jubilee clip to secure.

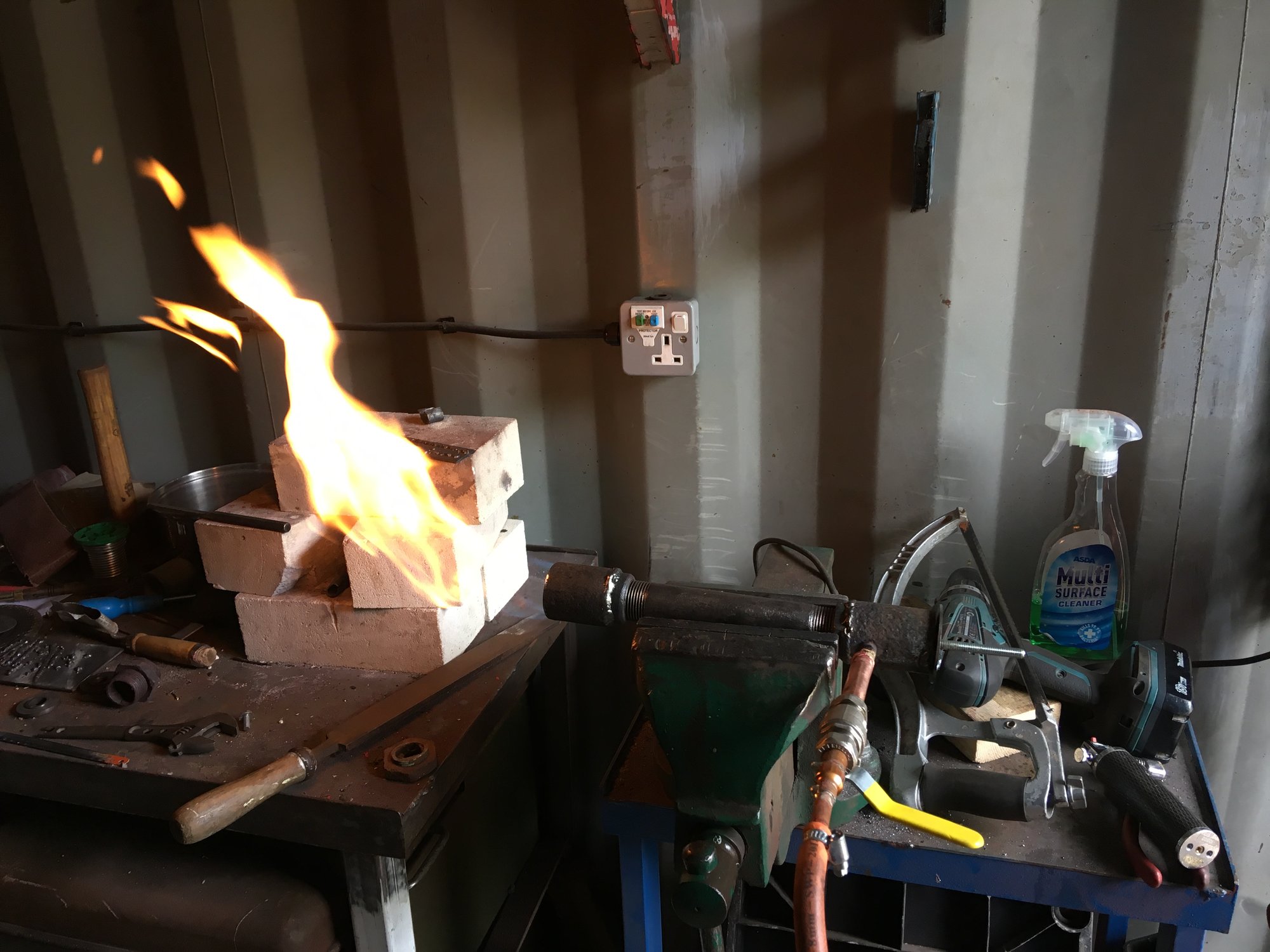

With the gas hose connected and a soapy water leak test it was time to ignite.

My 10mm blowtorch whilst good wasn't getting a big enough area of steel hot enough so needed to make something a little bigger.

Had a look round the web and youtube and opted for an idea off youtube, mainly because I had some scrap pipe and scaff tube that seemed to fit together quite well.

I've drawn this diagram to illustrate the basic principle.

The pipe is something like 1 1/2" diameter I think and this piece was threaded both ends so made an ideal choice. Cut some scaff tube for both ends and cut down a threaded coupler to create a nut for one end as I only had the one nut.

Welded the coupler to one scaff tube and the nut I had to the other.

Then needed to make a central thread to screw on the adjustable choke. An M8 bolt to some round bar would suffice for this.

Needed to create some round cutouts in the top scaff tube piece to allow the choke to sit flat onto the tube when fully screwed down, out with the file and cut a couple of cutouts.

welded into position

The basis of the gas jet is a mig tip screwed into a pipe. I had some 12mm OD steel tube so cut a couple of inches of that and drilled an tapped an M6 threaded hole. Needed some way to fit the 15mm gas ball valve to this pipe so brazed on some 15mm copper pipe, the 12mm steel pipe fitted nicely inside the 15mm copper pipe.

The tube welded into the scaff tube head with the mig tip screwed in place.

all screwed together

with the valve on needed a way to fit the 8mm ID hose to the 15mm pipe so drilled down the centre of an M8 bolt and cut off the head. A 15 to 10mm reducer and an inch or so of 10mm pipe got me down to an ID that the drilled bolt could fit into and brazed it into position. Ran some of the braze into the threads to stop gas leaking down the threads. Hose fits on well with a jubilee clip to secure.

With the gas hose connected and a soapy water leak test it was time to ignite.