Hello, as I've gotten an old air compressor with an excellent motor but the tank (at least to me) has a lot of steel missing on the inside due to rusting, tank is from 2011 but it has never been drained, and I don't feel ok with using that tank, I wanted to to the gas bottle to air tank thing. I have just a couple of questions about it.

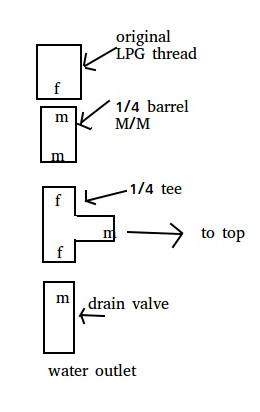

As some of you may know the tap thread is not a standard one, its below 1/2 but bigger than other sizes, so my plan will be to simply re-thread that brass valve with a 1/4 thread. a question about this, what kind of drill bit I have to use before I apply the 1/4 tap? I have a threader set and already did other threads but never a 1/4. In my threader set I got the drill bit for M12, which is 10.5mm, is that any good for the purpose? alternatively I have an 11mm one.

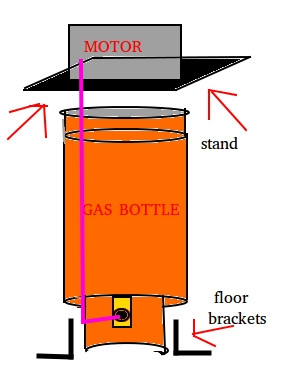

As illustrated on the images I plan to put the bottle upside down, with a tee installed so that I can drain moisture easily.

I wanted to weld 3 brackets on the handle so that I can screw this on the floor, and I would like to weld a sheet on the top on which i could mount the motor. May I weld these items on the specified part without ruining the pressure vessel? I think it won't be a problem because they are not the vessel itself but I'd like to ask anyway.

The pink line will be a copper pipe going from the compressor motor to the bottle, as ideally I would like to simply have a line going there and then have the pressure switch, manometers on the top, but I am not sure if this will give false readings or it can't be done as this items would need to be installed directly on the tank

Thank you for any reply

As some of you may know the tap thread is not a standard one, its below 1/2 but bigger than other sizes, so my plan will be to simply re-thread that brass valve with a 1/4 thread. a question about this, what kind of drill bit I have to use before I apply the 1/4 tap? I have a threader set and already did other threads but never a 1/4. In my threader set I got the drill bit for M12, which is 10.5mm, is that any good for the purpose? alternatively I have an 11mm one.

As illustrated on the images I plan to put the bottle upside down, with a tee installed so that I can drain moisture easily.

I wanted to weld 3 brackets on the handle so that I can screw this on the floor, and I would like to weld a sheet on the top on which i could mount the motor. May I weld these items on the specified part without ruining the pressure vessel? I think it won't be a problem because they are not the vessel itself but I'd like to ask anyway.

The pink line will be a copper pipe going from the compressor motor to the bottle, as ideally I would like to simply have a line going there and then have the pressure switch, manometers on the top, but I am not sure if this will give false readings or it can't be done as this items would need to be installed directly on the tank

Thank you for any reply