Burdekin

Chief Bodger

- Messages

- 6,659

- Location

- Aberdeen

I just wanted to say what an excellent forum you have here. I read the forum quite often but have never posted.

Many moons ago I did an apprenticeship as a fitter and turner in a remote bauxite mine in Cape York in Australia. Absolutely great place to do an apprenticeship and live (for a while) and I learnt the basis for all my trade skills here from some really fine tradesman. The mine was a great place to do my apprenticeship and we were moved from section to section to learn the different aspects of the trade. I also fancied learning to weld and fabricate so I asked the boilershop supervisor if he would mind me spending time in his shop which he didn't have a problem with so I got permission from the apprentice master and I got to spend a few months in the boilershop. Being young and keen I worked hard, did heaps of overtime and spent time with all the boilermakers who I asked loads of questions. It turned out I picked up welding very easily with good coaching from the tradesman and I also went on two welding courses and got a couple of welding tickets. I've always thoroughly enjoyed fabricating ever since.

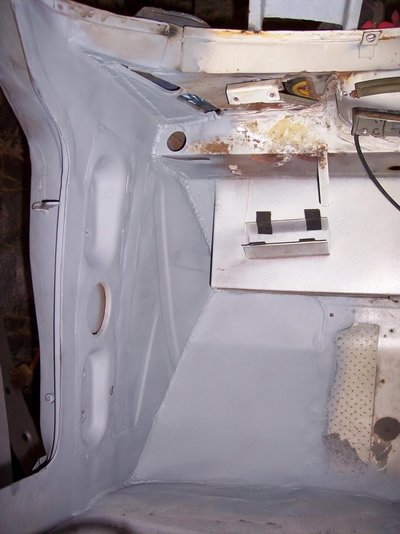

After my apprenticeship my old boilershop supervisor put me in charge of the pumps and bores section which also overhauled and made all the vibrating screens for the process plant so I continued to do fabricating as part of my job making new panels for the vibrating screens and helped rebuild the ship loader after it was blown into the river during a cyclone etc. After leaving the mine I spent two years working as a tradesman and in one job I did a lot of Tig welding stainless piping. When I had finally saved enough to put myself through uni it was off to do mechanical engineering then worked in mines throughout Australia until 10 years ago when I moved to Aberdeeen in Scotland to work in the oil industry and offshore in the north sea. Spent 4 years working hard offshore and in the office before I decided an office job is more what I wanted so now I'm based in the office full time. I've always continued to build and fix things in my spare time from beach buggies, old cars to houses. Now I pretty much just work on my two old Volvos in my workshop, a 1966 Amazon Estate and a 1970 P1800E. The Amazon is pretty much standard and I'm currently scrapping the underseal off and have done a couple of wee weld repairs, have a few more to do before I paint the underside. The P1800 is a major project, I've rebuilt quite a lot of it as they rust quite badly so many days of fabricating and welding so far with many more to come. I'm modernising the P1800 and welding it onto an extended MX5 so I still have a lot of work to do to finish this project but it is really enjoyable and couldn't live without my workshop and projects. I'm also lucky to have a very tolerant wife who doesn't mind me working late at nights or weekends in my workshop.

Anyway that is pretty much me, I probably won't post much here as I post regularly on the Volvo forum but will continue to linger in the background here and enjoy this fine forum as well...

Many moons ago I did an apprenticeship as a fitter and turner in a remote bauxite mine in Cape York in Australia. Absolutely great place to do an apprenticeship and live (for a while) and I learnt the basis for all my trade skills here from some really fine tradesman. The mine was a great place to do my apprenticeship and we were moved from section to section to learn the different aspects of the trade. I also fancied learning to weld and fabricate so I asked the boilershop supervisor if he would mind me spending time in his shop which he didn't have a problem with so I got permission from the apprentice master and I got to spend a few months in the boilershop. Being young and keen I worked hard, did heaps of overtime and spent time with all the boilermakers who I asked loads of questions. It turned out I picked up welding very easily with good coaching from the tradesman and I also went on two welding courses and got a couple of welding tickets. I've always thoroughly enjoyed fabricating ever since.

After my apprenticeship my old boilershop supervisor put me in charge of the pumps and bores section which also overhauled and made all the vibrating screens for the process plant so I continued to do fabricating as part of my job making new panels for the vibrating screens and helped rebuild the ship loader after it was blown into the river during a cyclone etc. After leaving the mine I spent two years working as a tradesman and in one job I did a lot of Tig welding stainless piping. When I had finally saved enough to put myself through uni it was off to do mechanical engineering then worked in mines throughout Australia until 10 years ago when I moved to Aberdeeen in Scotland to work in the oil industry and offshore in the north sea. Spent 4 years working hard offshore and in the office before I decided an office job is more what I wanted so now I'm based in the office full time. I've always continued to build and fix things in my spare time from beach buggies, old cars to houses. Now I pretty much just work on my two old Volvos in my workshop, a 1966 Amazon Estate and a 1970 P1800E. The Amazon is pretty much standard and I'm currently scrapping the underseal off and have done a couple of wee weld repairs, have a few more to do before I paint the underside. The P1800 is a major project, I've rebuilt quite a lot of it as they rust quite badly so many days of fabricating and welding so far with many more to come. I'm modernising the P1800 and welding it onto an extended MX5 so I still have a lot of work to do to finish this project but it is really enjoyable and couldn't live without my workshop and projects. I'm also lucky to have a very tolerant wife who doesn't mind me working late at nights or weekends in my workshop.

Anyway that is pretty much me, I probably won't post much here as I post regularly on the Volvo forum but will continue to linger in the background here and enjoy this fine forum as well...