whensparksfly

Member

- Messages

- 658

- Location

- ireland

how do you all get a straw coloured steel tig weld I want to hear your views on this topic.

how do you all get a straw coloured steel tig weld I want to hear your views on this topic.

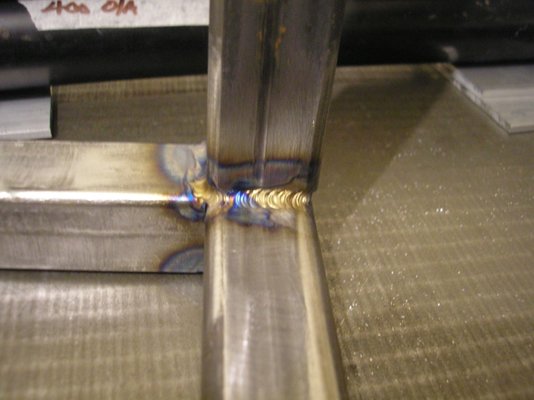

Not really* although i wasn't rushing either. Length of the weld is another reason why it came out golden/straw... if it'd been 50 x 50 x 3 box the weld would've probably been darker (mostly blues probably) because while a #7 cup isn't exactly big most of the weld along one side of 25mm box stays under the cup even when you wrap the corners- i stopped short at the right of the pic and the weld along that face i purposely left underfilled as stuff is to be welded onto that corner later

If it'd been 1.5mm wall there'd be more heat tinting in general and the weld would've been darker despite welding at 60ish amps instead of the 110 i was using. Less mass to the part = the heat travels further.

* Don't get me wrong, i'm not knocking the guy as he's waaaaay neater than i'll ever be but watch how sloooooowly he's welding and how he keeps turning the part so the weld is always right in front of him

Some of the reasons why i'll never be that neat are probably down to hand steadiness but mostly it's down to patience. I weld stainless a chunk faster than that and aluminium a LOT faster. I want to finish, get paid and go to the pub, not post pictures of pretty welds on faceache

never quite understood these motorsport welders.