Thanks in anticipation.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to make an inside flange

- Thread starter nickk

- Start date

daedalusminos

Member

- Messages

- 2,326

- Location

- Norwich

Can't you cut a square from the corner then fold up each edge and solder (or similar)?

I think the only way you form that in a continuous flange would be to press it from a sheet then trim the excess....that would require tooling and a press.

I think the only way you form that in a continuous flange would be to press it from a sheet then trim the excess....that would require tooling and a press.

AndersK

Member

- Messages

- 1,490

- Location

- Sweden

If you can accept round corners it would much easier to flip that flange.

Whit a sharp corner it will require a lot of stretching in a small area.

If you want to give it a go anyway I would start with a blunt chisel or bolster in the middle of the triangular area to stretch and work slowly outwards.

Don't cut the excess to a corner, fillet it to avoid tearing.

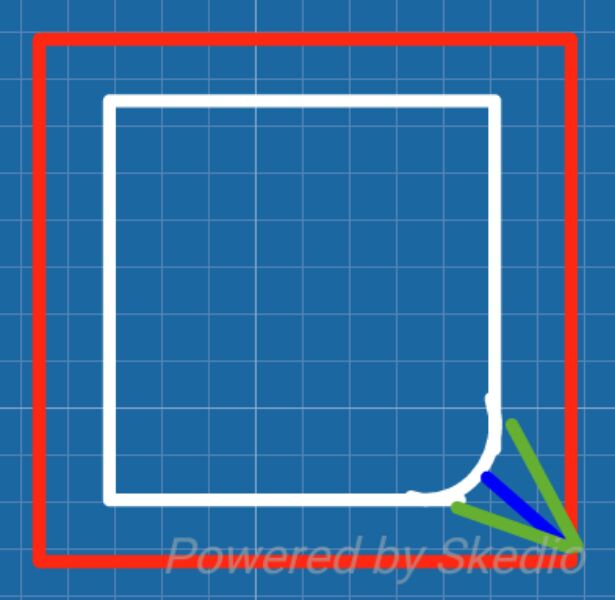

Red lines is your template.

White is sheet metal

Begin stretching along blue line and work towards the green.

Haven't done much in copper but I assume you need to stop and anneal multiple times.

Whit a sharp corner it will require a lot of stretching in a small area.

If you want to give it a go anyway I would start with a blunt chisel or bolster in the middle of the triangular area to stretch and work slowly outwards.

Don't cut the excess to a corner, fillet it to avoid tearing.

Red lines is your template.

White is sheet metal

Begin stretching along blue line and work towards the green.

Haven't done much in copper but I assume you need to stop and anneal multiple times.